Automatic packaging machine

A technology of automatic packaging machine and transmission mechanism, which is applied in the directions of packaging, multiple packages, transportation and packaging, etc. It can solve problems such as poor sealing, reduced production efficiency, and manual coding, so as to improve fatigue resistance and use Longer service life, double production efficiency, and avoid the effect of weak sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

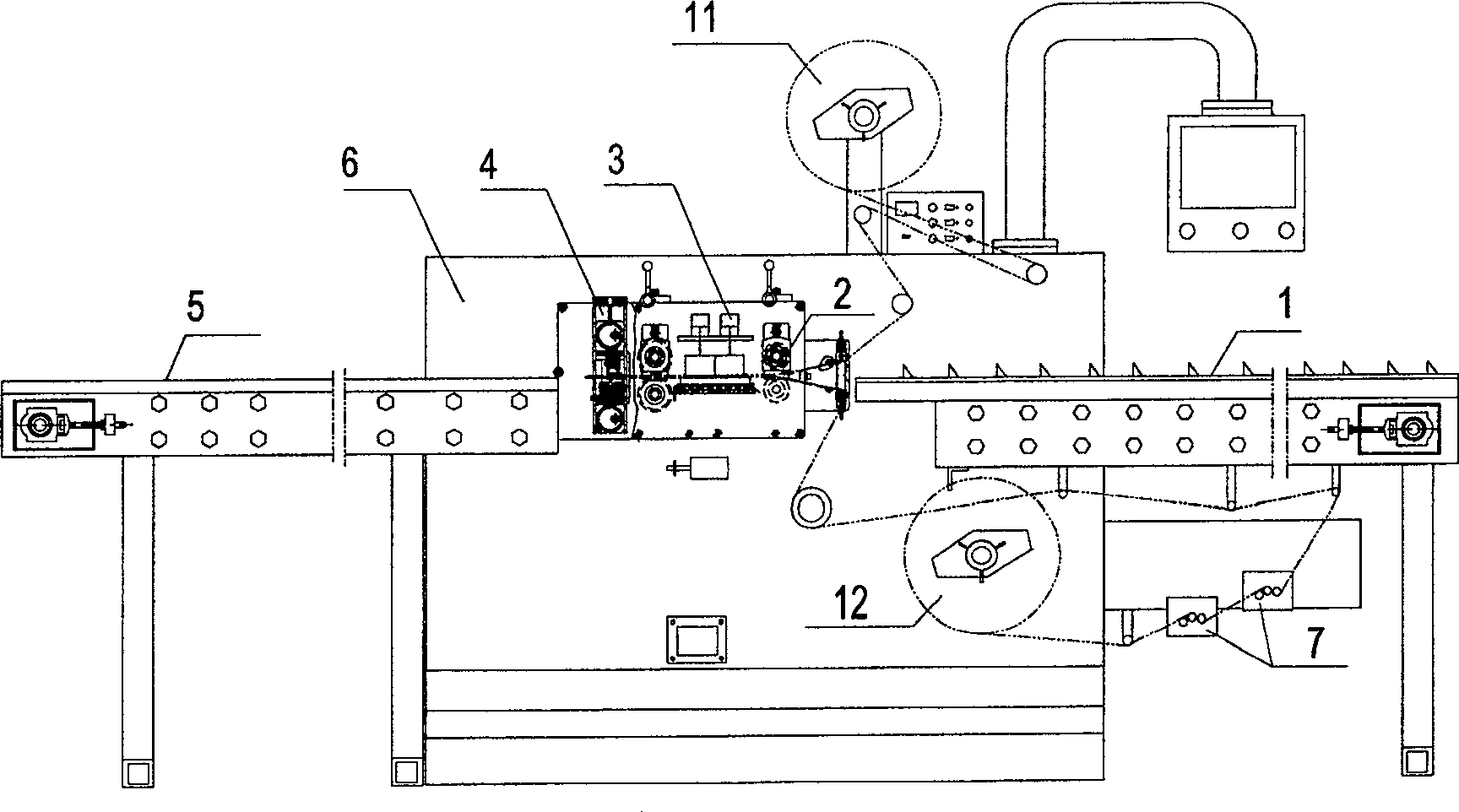

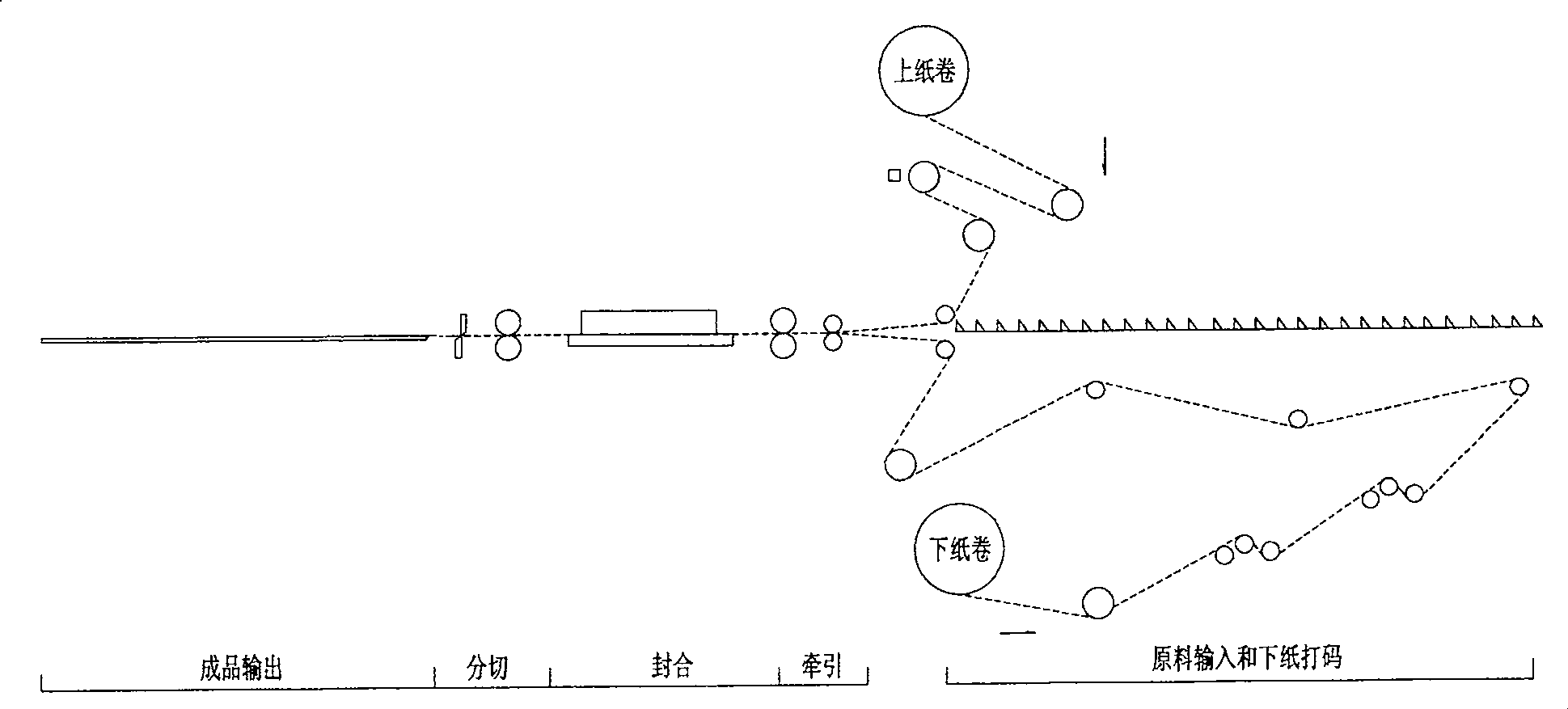

[0031] Embodiment: the technical scheme of the utility model is: as figure 1 As shown, the automatic packaging machine includes raw material input system 1, paper tape traction system 2, synchronous coding system 7, sealing and forming system 3, cutting system 4, finished product output system 5, electric control system, frame 6, chassis and accessories. The upper paper frame 11 and the lower paper frame 12 are respectively used for installing paper rolls used for packaging. Its process is as figure 2 As shown, under the traction of the lower paper belt, it drives the shaft of the coding machine to rotate, and the lower paper is coded through the reversal of the ink wheel and the type wheel. At the same time, the raw material input system inputs the product to be packaged between the upper and lower paper belts, and the upper and lower paper The belt is pulled into the sealing and forming system, and the sealing mold is used to seal and package it. After the cutting system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com