Decorative element comprising heating element made of carbon material

A technology for decorative elements and heating elements, which can be applied to ohmic resistance heating parts, electric heating devices, electrical components, etc., and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

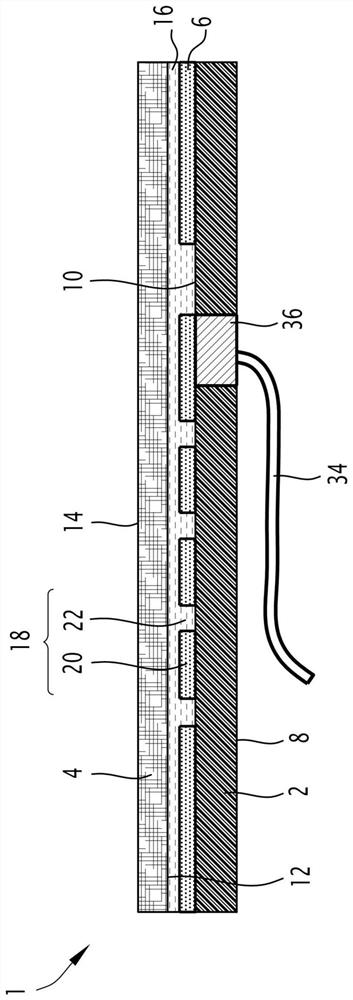

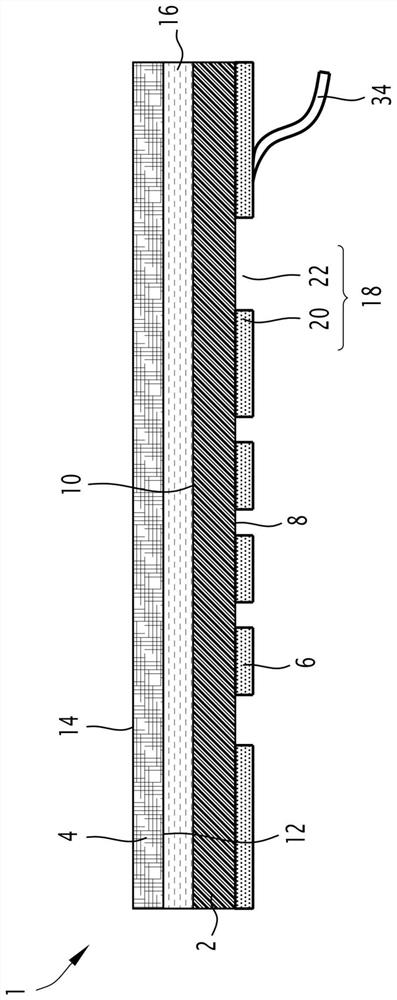

[0032] refer to figure 1 and figure 2 , describes a vehicle trim element 1 comprising at least a support layer 2 , a decorative layer 4 and a functional layer 6 . Such trim elements are intended, for example, to form door panels, dashboard covers or center console covers or the like.

[0033] The support layer 2 is arranged to impart its shape and mechanical properties, in particular its stiffness, to the decorative element 1 . Thus, the support layer 2 is eg made of a substantially rigid material for a door panel, eg plastic or composite material. According to one embodiment, the support layer 2 is made of a composite material (also known under the English name NFPP for "Natural Fiber Polypropylene") comprising natural fibers in a polypropylene matrix. Natural fibers are selected, for example, from flax, hemp, kenaf and / or wood. The support layer 2 is formed, for example, by hot pressing in a pressing tool having the desired shape of the support layer 2 corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com