Jam production equipment

A production equipment and jam technology, applied in the field of jam production equipment, can solve the problems of jam cover falling easily, affecting production efficiency, affecting sealing performance, etc., and achieving the effects of preventing tilting, improving production efficiency and preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

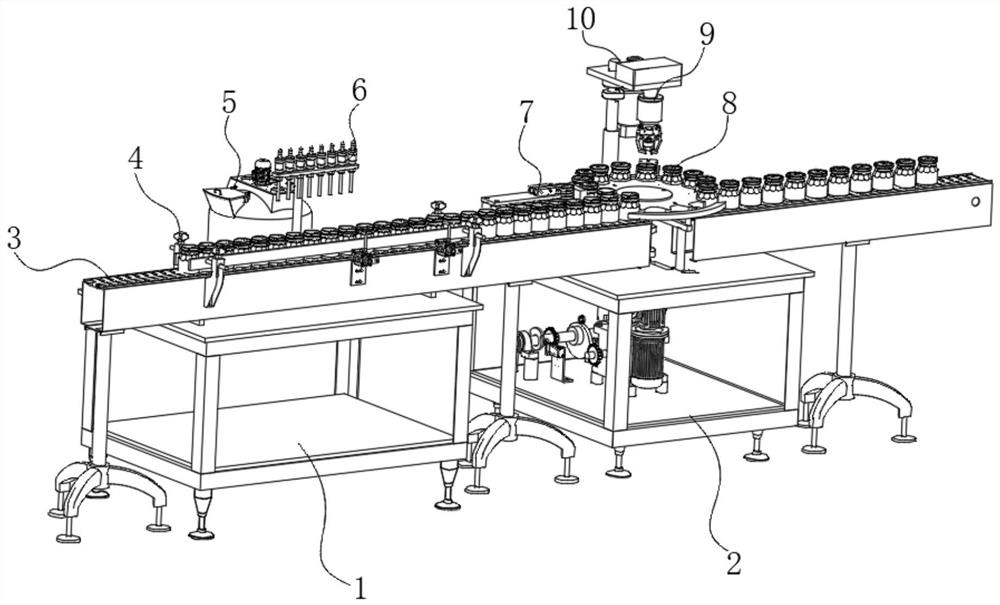

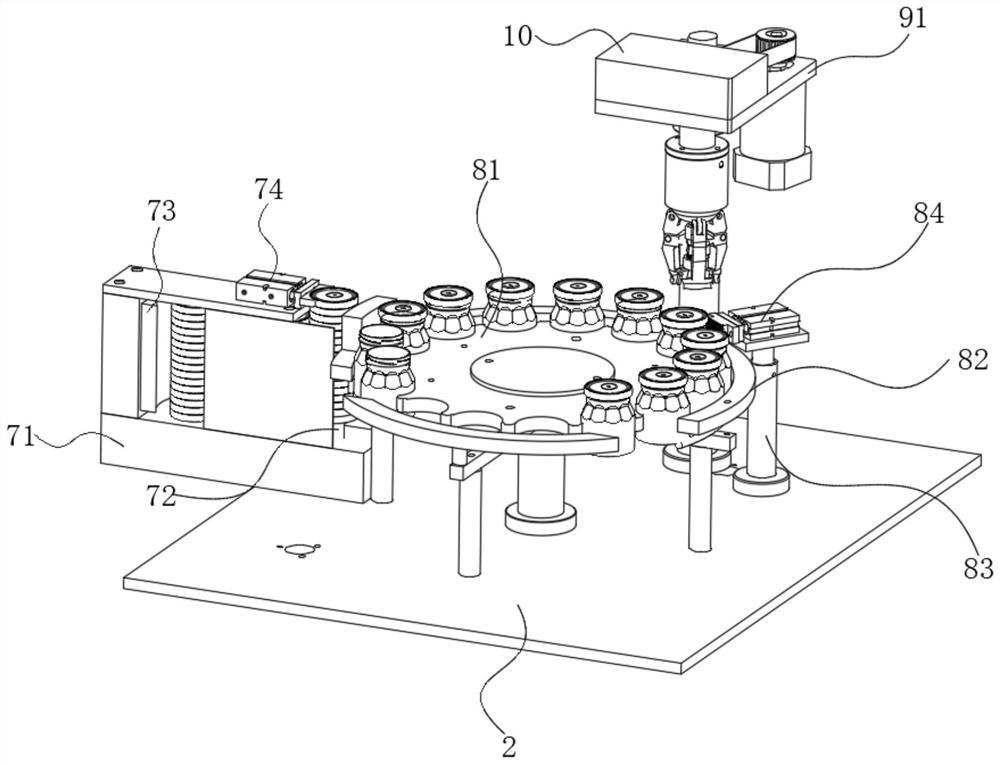

[0030] refer to figure 1 , the present invention provides a technical solution: a jam production equipment, comprising a base 1, a base 2 2, a conveyor belt 3, a mixing bucket 5, an upper cover assembly 7, a turntable assembly 8 and a screw cap assembly 9, wherein the conveyor belt 3 is erected above the base one 1 and the base two 2;

[0031] The top of the base-1 is fixed with a mixing barrel 5, and the mixing barrel 5 is connected with a filling head 6 by a flexible tube. 3. The guide plates 4 are fixed on both sides by adjusting bolts. The guide plates 4 can adjust the jam jar to be directly below the filling head 6. Specifically, the guide plates 4 can adjust the position of the jam jar by adjusting the bolts. , so that the jam jar is in the middle position of the conveyor belt 3, which is convenient for filling by the filling head 6, and multiple jam jars can be filled at the same time through the provided multiple filling heads 6, which increases the production efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com