A kind of trace element composite strengthening high-strength aluminum-lithium alloy and preparation method thereof

A trace element, high-strength technology, applied in the field of aluminum-lithium alloy materials, can solve the problems of complex process, easy oxidation of Li element, increase cost, etc., and achieve the effect of avoiding complex process, inhibiting grain growth and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

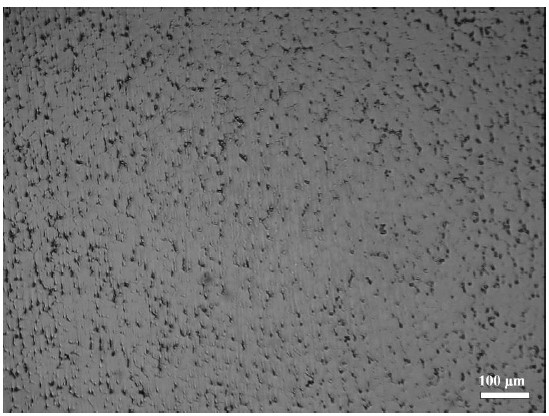

Embodiment 1

[0040]The preparation of high-strength cast aluminum-lithium alloy by the method of the present application includes the following steps:

[0041] S1: Prepare raw materials according to the required alloy composition, and preheat the raw materials: Considering the burning loss of elements, Cu, Li, Mg, and Zn all use master alloys in the configuration of raw materials, which are Al-60%Cu, Al- 20%Li, Al-30%Mg, Al-30%Zn, the burn loss rates considered for the above master alloys are 5%, 10%, 10%, and 5%, respectively. The prepared raw materials were kept in an air heating furnace for 1 hour at a temperature of 220°C. The master alloy of Mg and Li is dried in a vacuum drying oven to remove moisture.

[0042] S2: vacuum smelting the raw materials to obtain molten metal after smelting: before smelting, the graphite crucible needs to be coated with boron nitride coating, the mass fraction of solid boron nitride in the boron nitride coating must be greater than 70%, and the coating t...

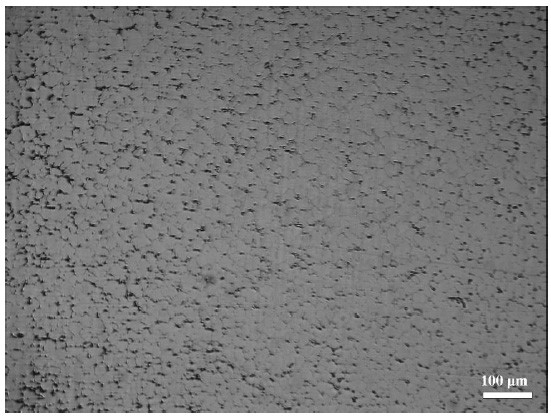

Embodiment 2

[0049] The preparation of high-strength cast aluminum-lithium alloy by the method of the present application includes the following steps:

[0050] S1: Prepare raw materials according to the required alloy composition, and preheat the raw materials: Considering the burning loss of elements, Cu, Li, Mg, and Zn all use master alloys in the configuration of raw materials, which are Al-60%Cu, Al- 20%Li, Al-30%Mg, Al-30%Zn, the burn loss rates considered by the above master alloys are 5%, 15%, 10%, and 5%, respectively. The prepared raw materials were kept in an air heating furnace for 1 hour at a temperature of 220°C. The master alloy of Mg and Li is dried in a vacuum drying oven to remove moisture.

[0051] S2: vacuum smelting the raw materials to obtain molten metal after smelting: before smelting, the graphite crucible needs to be coated with boron nitride coating, the mass fraction of solid boron nitride in the boron nitride coating must be greater than 70%, and the coating t...

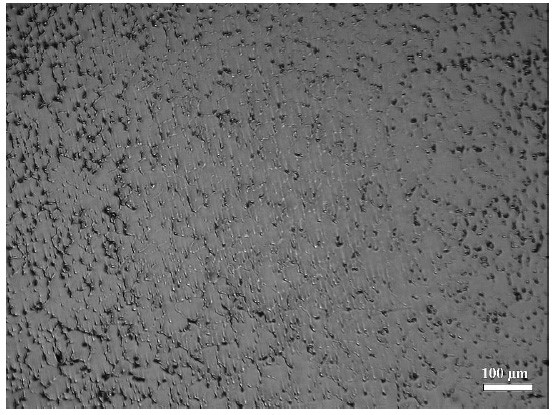

Embodiment 3

[0058] The preparation of high-strength cast aluminum-lithium alloy by the method of the present application includes the following steps:

[0059] S1: Prepare raw materials according to the required alloy composition, and preheat the raw materials: Considering the burning loss of elements, Cu, Li, Mg, and Zn all use master alloys in the configuration of raw materials, which are Al-60%Cu, Al- 20%Li, Al-30%Mg, Al-30%Zn, the burn loss rates considered by the above master alloys are 5%, 15%, 10%, and 5%, respectively. The prepared raw materials were kept in an air heating furnace for 1 hour at a temperature of 220°C. The master alloy of Mg and Li is dried in a vacuum drying oven to remove moisture.

[0060] S2: vacuum smelting the raw materials to obtain molten metal after smelting: before smelting, the graphite crucible needs to be coated with boron nitride coating, the mass fraction of solid boron nitride in the boron nitride coating must be greater than 70%, and the coating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com