Detachable prestressed steel bar truss laminated slab

A technology of prestressed steel bar and steel truss, which is applied in the field of laminated plate equipment, and can solve the problems of large volume and difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

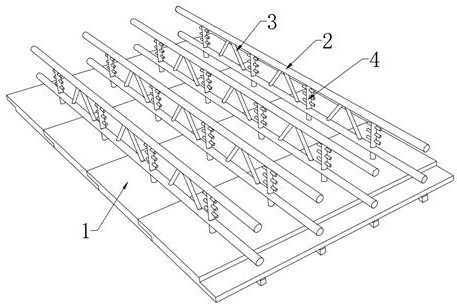

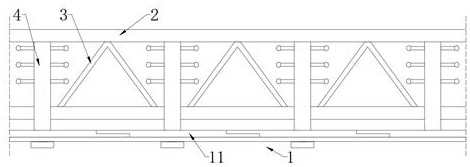

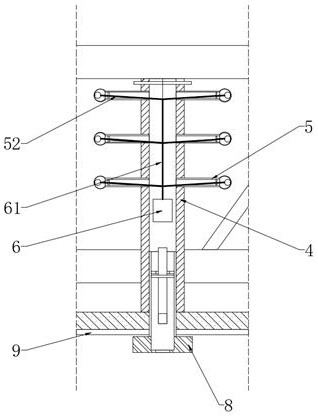

[0044] See Figure 1-9, a removable prestressed reinforcement truss stacking board, including formwork 1, formwork 1 fixed connection with multiple evenly distributed detection cylinders 4, multiple detection cylinders 4 fixed connection between two reinforced trusses 2, two reinforced trusses 2 fixed connection between multiple keel reinforcement 3, detection cylinder 4 fixed connected with multiple symmetrical settings of the branch measuring cylinder 5, multiple branch measuring cylinder 5 away from the detection cylinder 4 end fixed connection with a permeable filter membrane 51, permeable filter membrane 51 internally set finite expansion ball 52, Branch tube 5 internal sliding connection has a mobile plug 54, the detection cylinder 4 is provided with a heavy pull block 6, the upper end of the heavy pull block 6 is fixed to the main pull line 61, multiple limit expansion balls 52 are fixedly connected to the pull branch line 53, and multiple pull branch lines 53 are fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com