Small metal thin-wall part grabbing robot

A thin metal, robot technology, applied in the field of parts grabbing, can solve problems such as blanking grabbing, and achieve the effects of improving stability, improving the application effect of workpieces, and improving overall work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

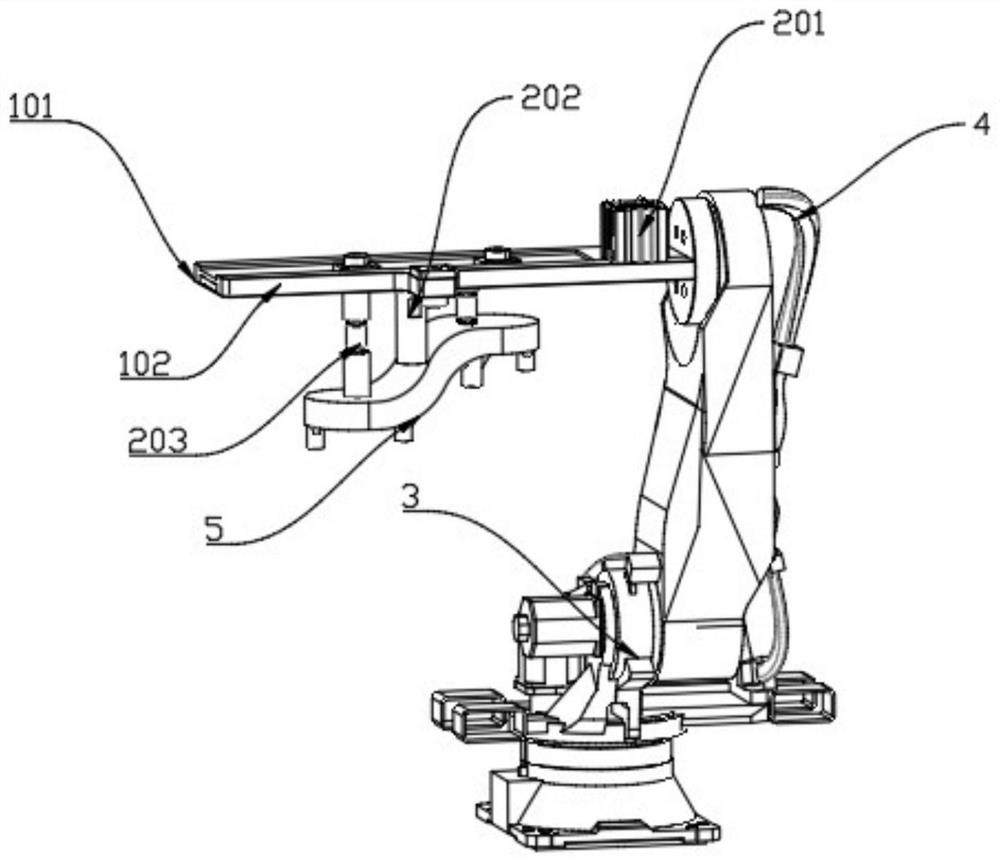

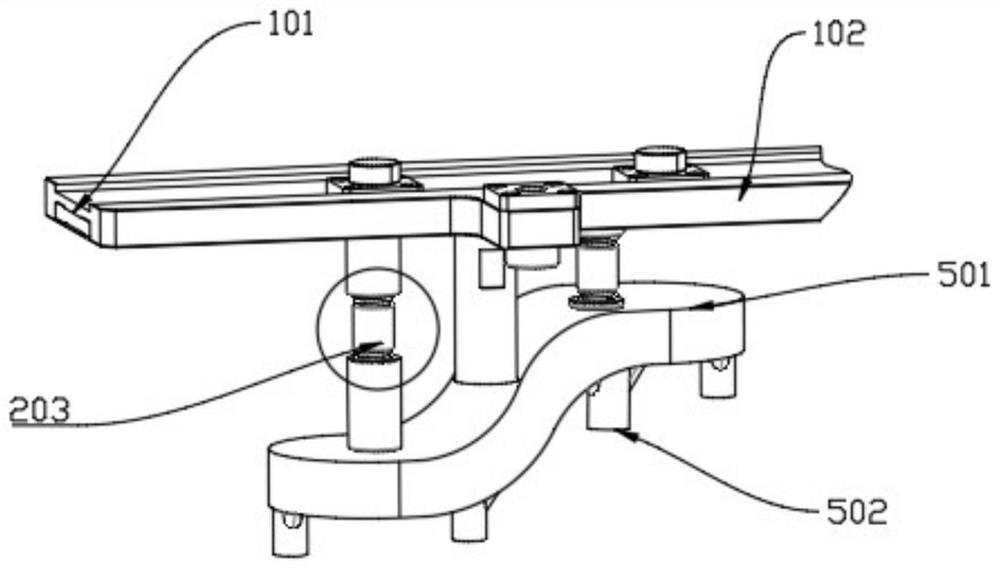

[0021] The invention provides a small-sized metal thin-walled parts grabbing robot comprising: a displacement drive device 23, a transmission assembly and a working assembly.

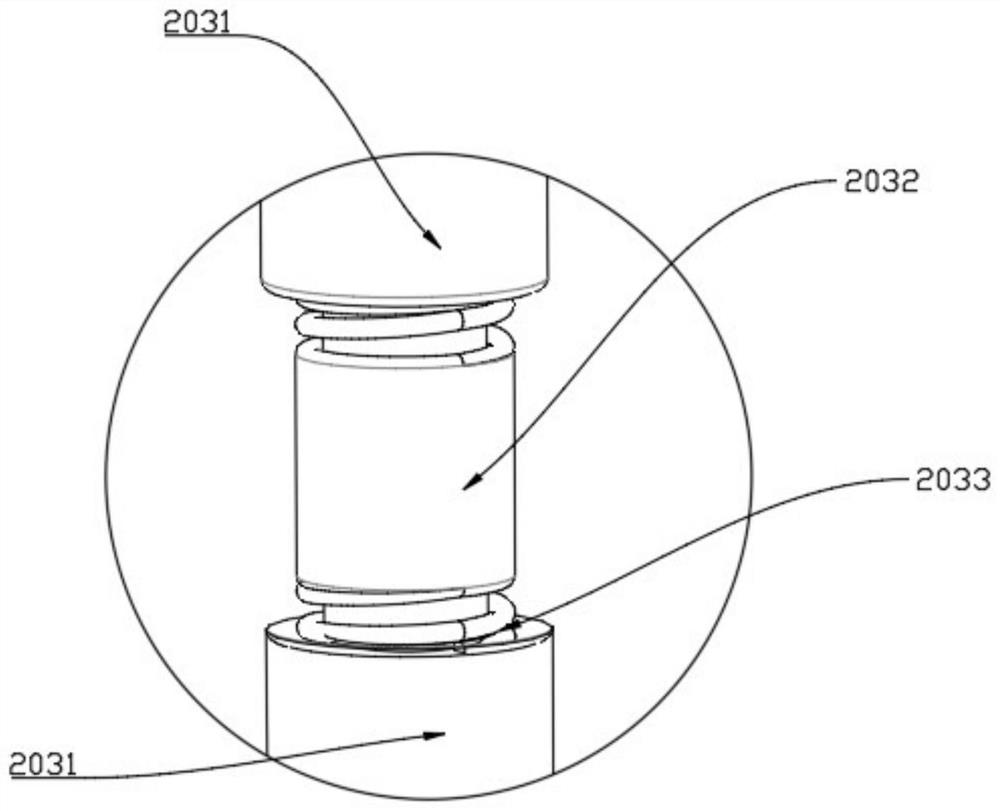

[0022] The transmission assembly includes an extension arm fixedly connected to the displacement drive device 23, and a moving slide rail 101 that is coaxially extended and fixedly connected inside the extension arm; a working assembly is movably connected with the moving slide rail 101, including The drive motor 201 fixedly connected to the upper end surface of the extension arm, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap