Abnormal sound automatic detection method and device and computer readable storage medium

An automatic detection and abnormal sound technology, which is used in manufacturing computing systems, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of lack of quantitative indicators, influence judgment, hearing loss, etc. The effect of wide range and high judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

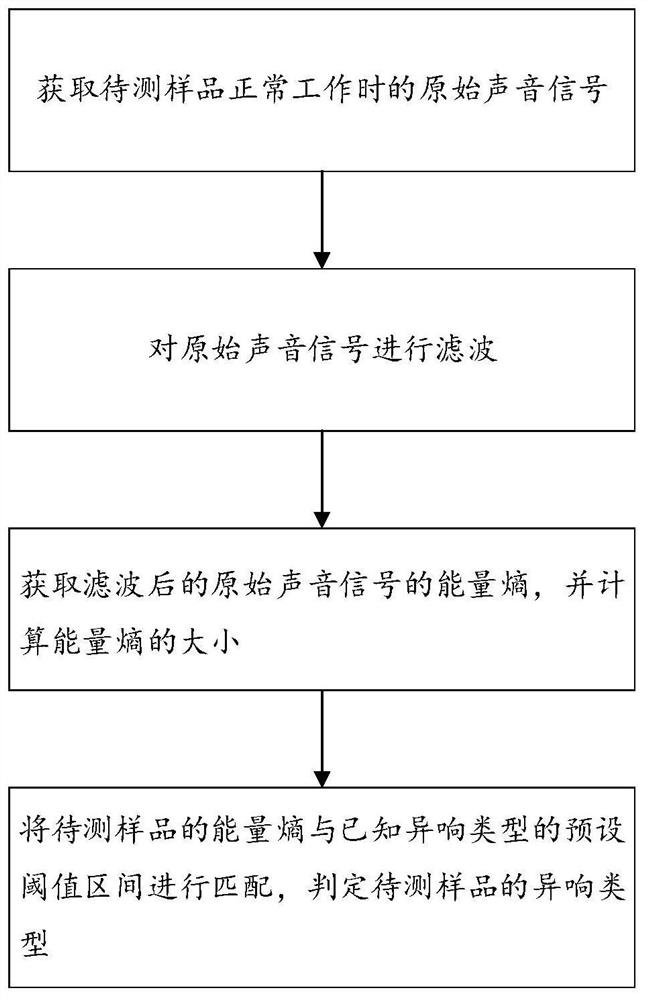

Method used

Image

Examples

Embodiment 1

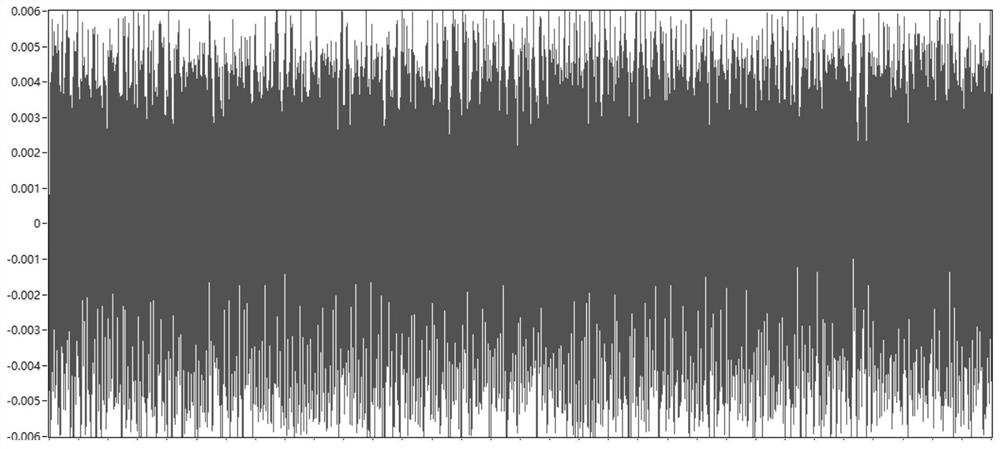

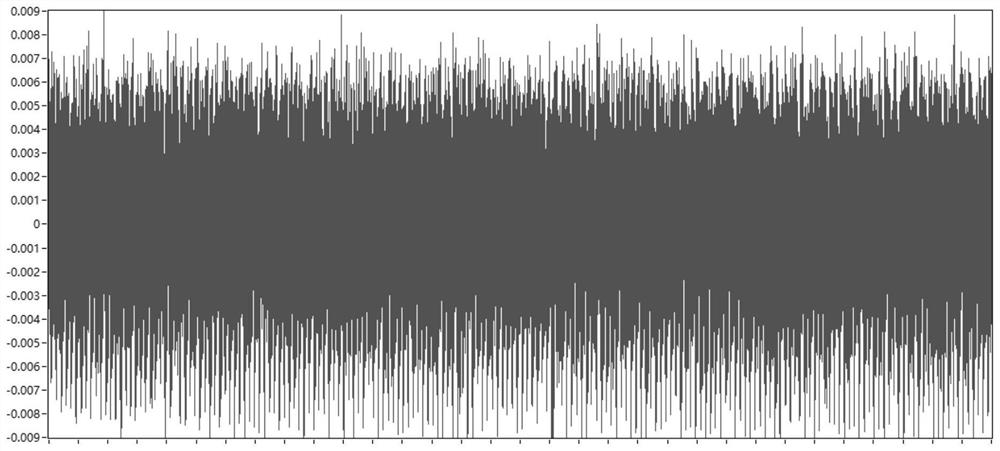

[0062] The motor produced by a certain manufacturer uses the abnormal sound automatic detection method provided by the invention to detect the abnormal sound of the motor product.

[0063] For the detection method, refer to the above-mentioned steps 1 to 5, which will not be repeated here.

[0064] According to long-term production experience, the abnormal sound of this type of motor can be divided into three situations: (1) No abnormal sound, indicating that the motor has no structural defects and the quality is qualified. (2) There is a type A abnormal sound, which indicates that there is a structural defect in the motor. (3) There is a type B abnormal sound, indicating that there is another type of defect in the motor.

[0065] After a lot of experiments, the threshold intervals are: [0, 0.18) means no abnormal sound, [0.18, 0.32) means type A abnormal sound, [0.2, ∞) means type B abnormal sound.

[0066] Three products were actually measured, namely Product 1, Product 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com