Bolt feeding equipment for assembling automobile hub bearing

A technology for bearing assembly and automobile wheel hub, applied in the field of bearing assembly, can solve the problems of time-consuming, labor-intensive, labor-intensive, and difficult bolt sorting and arranging process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

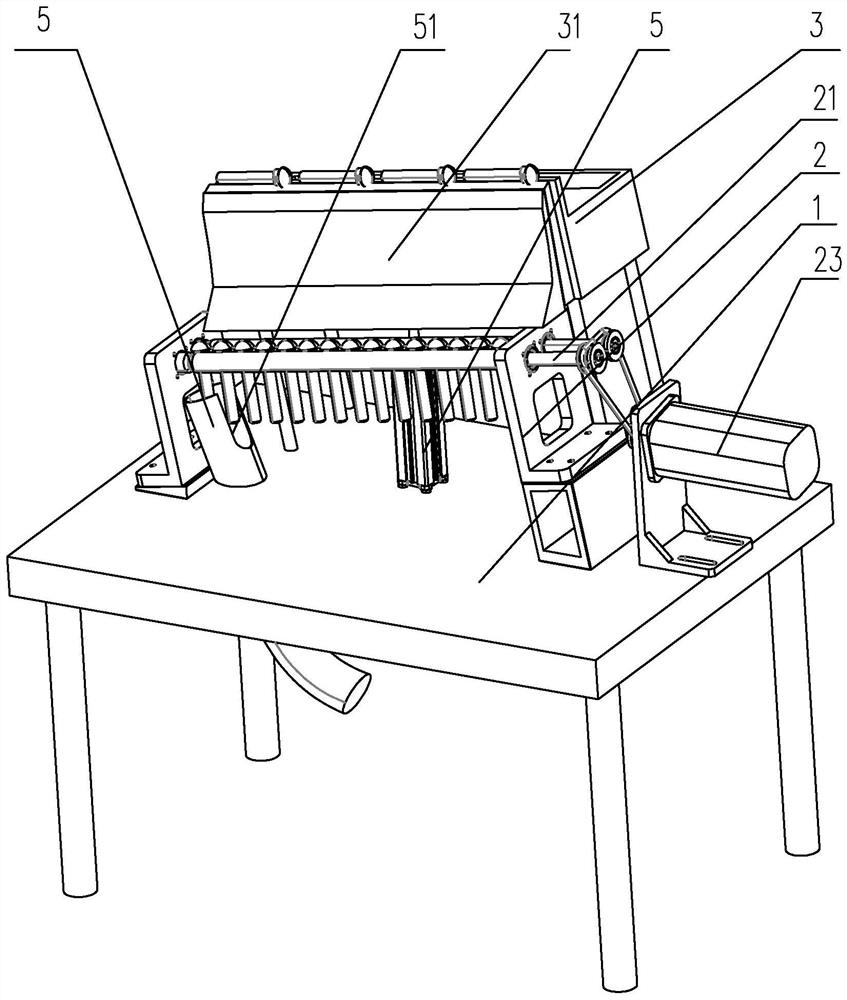

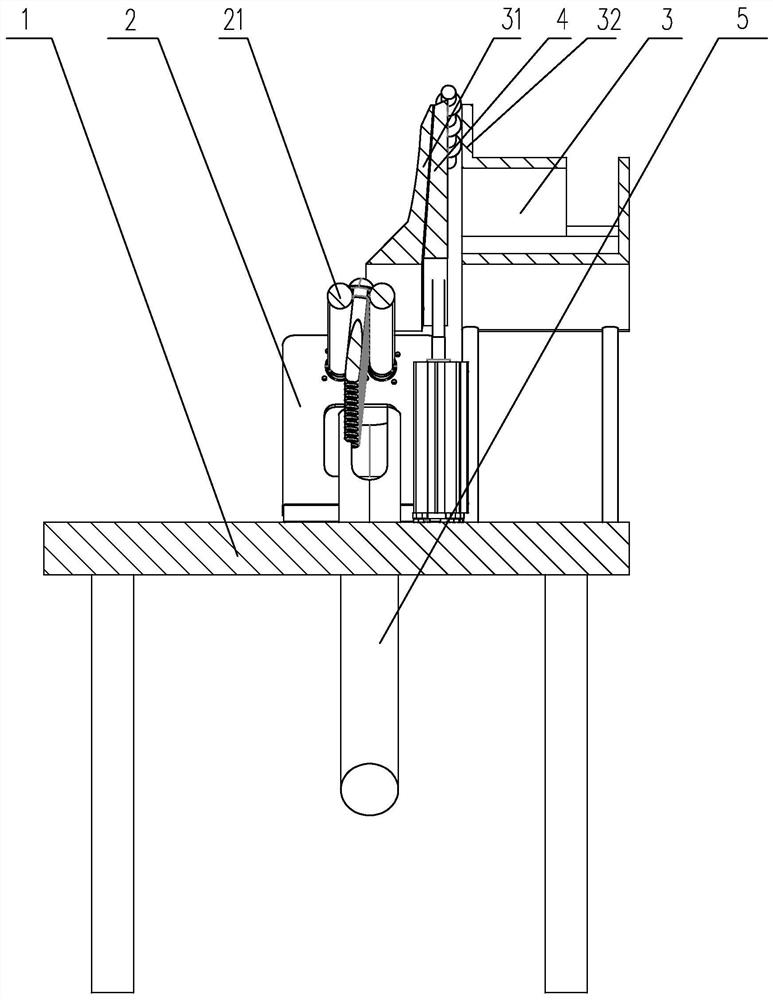

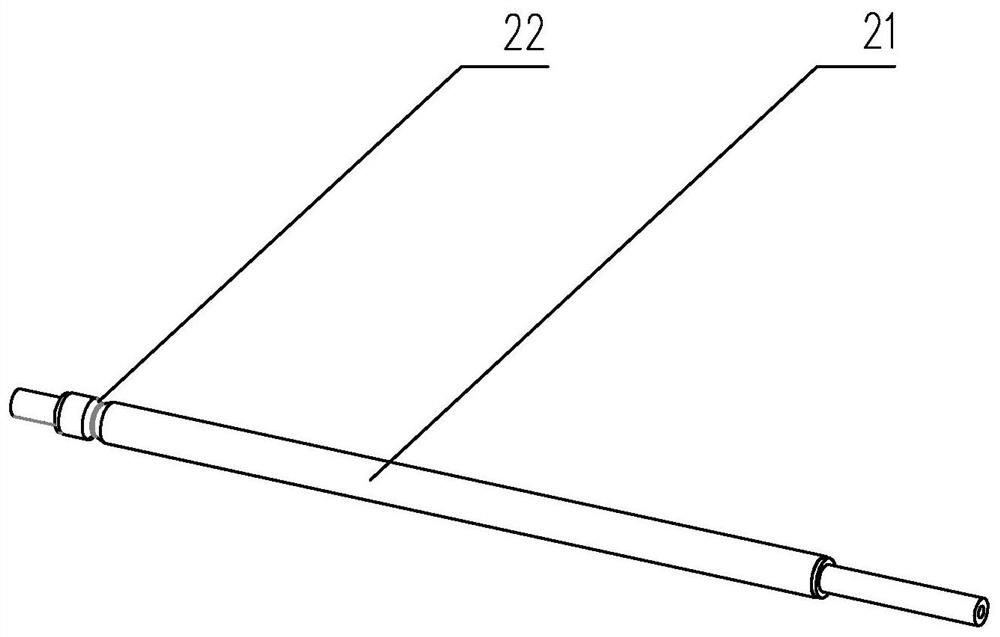

[0021] Embodiments of the bolt feeding equipment used in the assembly of automobile wheel hub bearings according to the present invention are as follows: Figure 1 to Figure 3 Shown: it includes a bracket 1 on which a conveying frame 2 is provided, a conveying guide groove is set on the conveying frame 2, the conveying guide groove is arranged obliquely, and the width of the conveying guide groove is proportional to the diameter of the bolt rod Adaptation, the support 1 is provided with a conveying pipe 5 corresponding to the end of the conveying guide groove, and the support 1 is provided with a accommodating cavity 3 on one side of the conveying frame 2 for accommodating bolts, and the accommodating cavity 3 is close to the conveying The side wall of the frame 2 is a guide wall 31. The guide wall 31 is provided with a guide slope for guiding the bolts to fall into the conveying guide groove. The accommodating cavity 3 is provided with a discharge port, which is close to the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com