Connecting structure of suspension bridge cable clamp and main cable and construction technology

A technology for connecting structures and suspension bridges, which is applied in the direction of suspension bridges, bridges, and bridge construction. It can solve the problems of PE sheath tearing, large force component of cable clips sliding down, and cable clips slipping, so as to achieve high friction and prevent water vapor. Intrusion and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

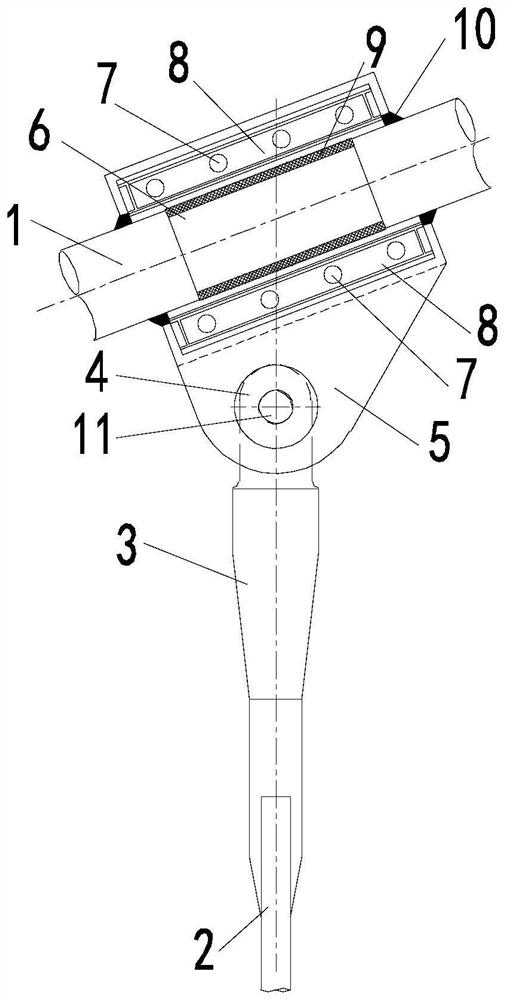

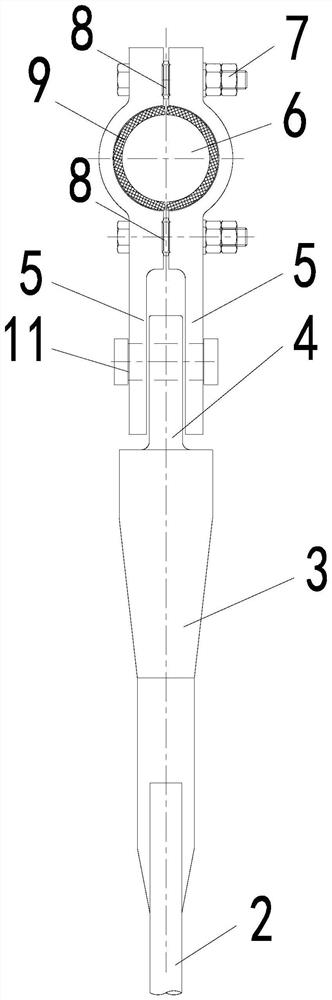

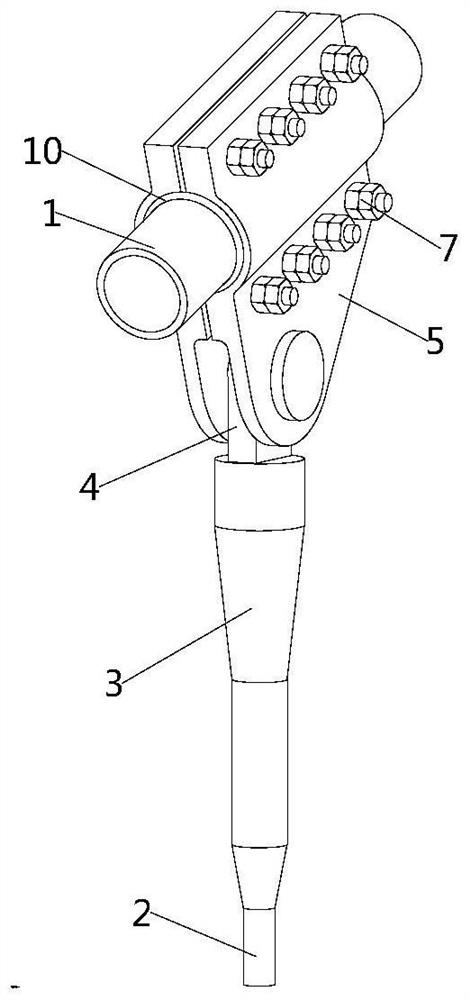

For this, refer to Figure 1 to Figure 4 As shown in the figure, a connection structure between a cable clamp of a suspension bridge and a main cable includes a main cable 1, a suspension cable 2, an anchor head 3 and an ear plate 4, and the suspension cable 2 and the ear plate 4 are respectively connected to both ends of the anchor head 3, The main cable 1 is a finished cable with a PE sheath, and also includes a zinc washer 9 and two connected splints 5. The splint 5 is rotatably connected to the ear plate 4, and the splint 5 includes a semi-circular arc shape in cross section. accommodating cavity, the zinc washer 9 is a semi-circular arc-shaped structure in cross section, the outer arc surface of the zinc washer 9 fits with the inner arc surface of the accommodating cavity, and the main cable 1 includes stripping PE. (Polyethylene) main cable surface 6, the main cable surface 6 after peeling off PE and the inner arc surface of the zinc washer 9 fit. By arranging the zinc w...

Embodiment 2

like Figure 5-Figure 10 As shown, the present embodiment provides a construction process for connecting the cable clamp of a suspension bridge to the main cable 1, including the following steps:

Step 1: Make PE stripping length marks and splint 5 length marks on the position of the cable clip on the PE surface of the main cable 1, then cut and peel off the PE on the surface of the main cable 1 according to the PE stripping length marks. The steel wire of the main cable 1 is exposed, and the dimension of the main cable surface 6 along the length direction of the main cable 1 after stripping the PE is equal to the dimension of the inner arc surface of the zinc gasket 9 along the length direction of the main cable 1;

Step 2: Buckle two pieces of zinc washers 9 into the main cable surface 6 after peeling off PE, so that the main cable surface 6 after stripping PE is in contact with the inner arc surface of the zinc washers 9;

Step 3: Align the two splints 5 and the correspondi...

Embodiment 3

In this embodiment, the main cable 1 is a finished cable with PE sheath, and its diameter is 143 mm; the main cable 1 after stripping PE is made of parallel galvanized steel wire, and its diameter is 121 mm;

Among them, the sling (rod) 2 is made of finished rigging, the anchor head 3 is in the form of a cold-cast anchor, the upper end is a single ear plate 4, and its thickness is 44mm; , The width of the mouth is 47mm to adapt to the thickness of the lug plate 4, and holes are opened on the plate for on-site installation with the pin 11 to connect with the lug plate 4.

[0040] The length of the two splints 5 is 340mm, the gap between the two splints 5 is 6mm, and the diameter of the inner arc surface of the accommodating cavity is 143mm to adapt to the diameter of the main cable 1; each splint 5 is on both sides of the main cable 1, A total of 8 bolt holes in 2 rows and 4 columns are symmetrically arranged to install the bolt connection pair. The specification is M20 high-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com