Fabricated flexible damping spiral anchor foundation and power transmission tower

A kind of screw anchor and prefabricated technology, which is used in infrastructure engineering, protection devices, sheet pile walls, etc., can solve the problems that horizontal force cannot be ignored and the bearing capacity of screw anchor foundation cannot be fully exerted, so as to shorten the construction period on site and save energy. Construction time and cost, the effect of high vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

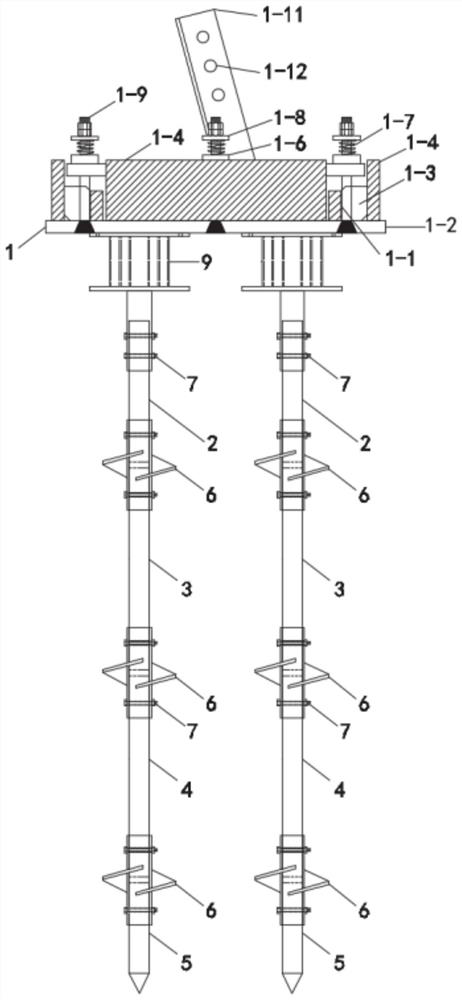

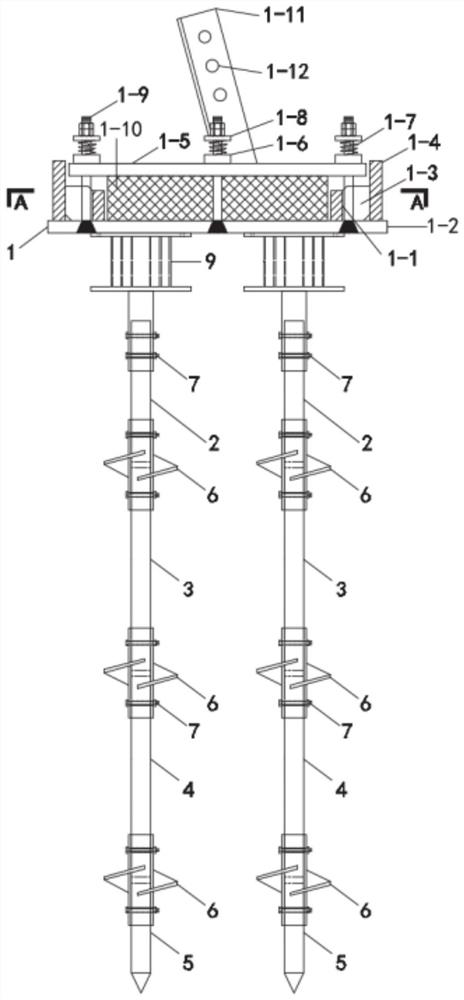

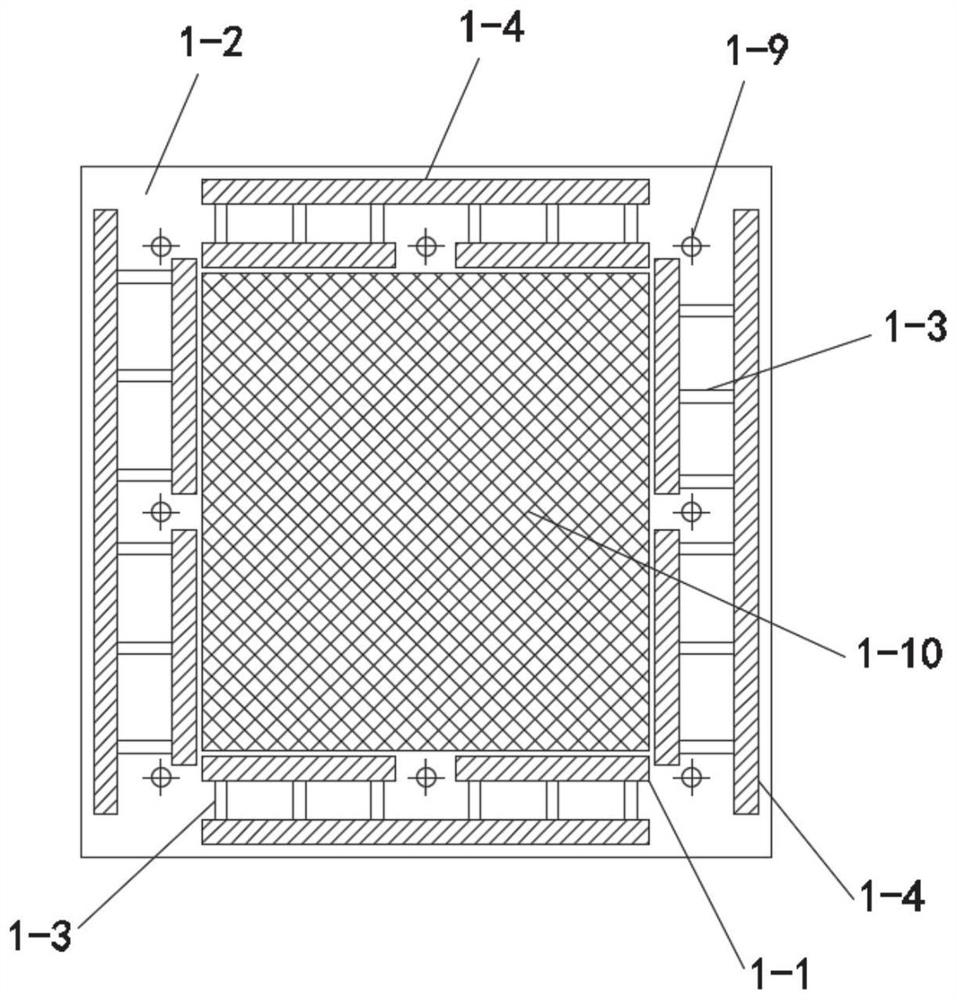

[0034] This embodiment provides an assembled flexible shock-absorbing screw anchor foundation, such as figure 1 and figure 2 As shown, it includes a shock absorbing platform 1, a flexible connecting section 9, a spiral anchor group, a blocking block, and an elastic pad 1-10. There are multiple spiral anchor groups at the bottom of the shock absorbing platform 1, and each spiral anchor group is connected through a flexible connection. The section 9 is connected with the shock absorbing platform 1, and the flexible connection between the spiral anchor group and the shock absorbing platform 1 is realized through the flexible connecting section 9, so as to reduce the horizontal force borne by the anchor rod.

[0035] Further, as shown in Figure 5(a), the flexible connecting section 9 includes a first connecting plate 9-1, a second connecting plate 9-2, a flexible pipe 9-3 and a connecting head 9-5, and the flexible pipe 9-3 One end is fixed with the first connecting plate 9-1, a...

Embodiment 2

[0062] This embodiment provides an assembled flexible shock-absorbing spiral anchor foundation. The flexible shock-absorbing spiral anchor foundation adopts the structure described in Embodiment 1, and a connecting piece 1-11 is installed on one side of the cap top plate 1-5, and through the connection The piece 1-11 is connected with the upper structure; multiple mounting holes 1-12 are opened on the connecting piece 1-11 to form multiple fixing points.

[0063] In this embodiment, the connecting piece 1-11 is an angle steel connecting piece, and the angle steel connecting piece is welded together with the platform top plate 1-5.

Embodiment 3

[0065] This embodiment provides an assembled flexible shock-absorbing spiral anchor foundation, which is different from Embodiment 1 in that prestressed steel bars are set in the spiral anchor plate 6 to further enhance the strength and rigidity of the spiral anchor plate 6. Other structures and embodiments One is the same and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com