Structure and process for extracting gas from lower protective layer through high-position high-drainage roadway and downward drilling hole

A technology of protective layer and high drainage roadway, which is applied in the direction of earthwork drilling, gas discharge, mining fluid, etc., can solve the problems of lack of construction gas control roadway, poor drainage effect of high drainage roadway, high level of high drainage roadway, etc. Achieve safety and social benefits, improve drainage effect, and ensure gas safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

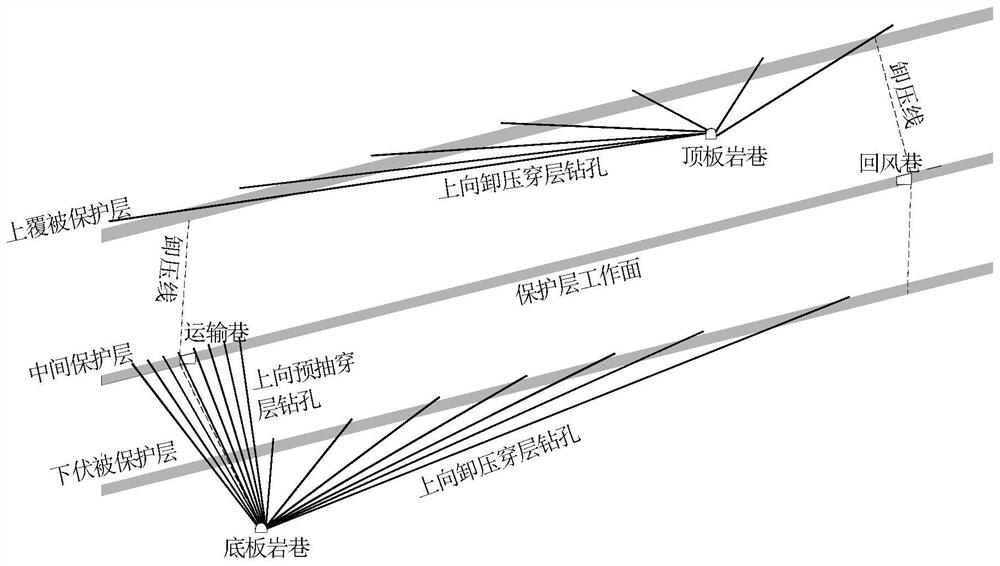

[0070] like Figure 4 , 5 As shown in the figure, a high-level high-draining roadway and a downward drilling hole to extract the lower protective layer gas structure, including a protective layer 1, a protected layer 2, a protective layer working face cutout 3, a return air slot 4, and a belt conveyor slot. 5. High-level and high-drainage lanes 6, first boreholes 7, second boreholes 8, third boreholes 9, airtight walls 10, and extraction pipelines 11.

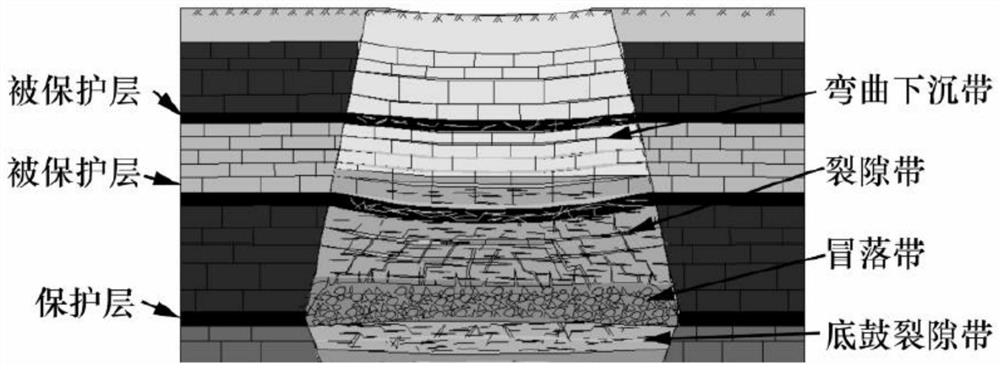

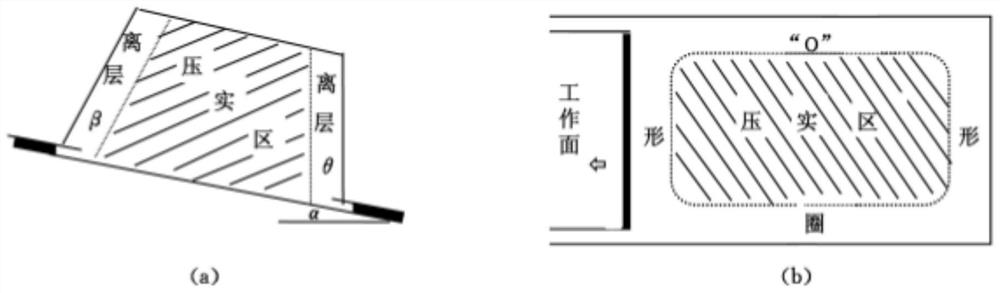

[0071] The coal seam or ore seam that is mined first to eliminate or weaken the danger of outburst or rock burst of the adjacent coal seam is called the protective layer; the outburst or rock burst danger of the adjacent coal seam is eliminated or weakened by the mining pressure relief of the protective layer, which is called the protective layer. protected layer. According to the different positions of the protective layer and the protected layer, it can be divided into the upper protective layer and the lower protective lay...

Embodiment 2

[0096] The invention also discloses a process for constructing the above-mentioned high-level high-drainage roadway and downward drilling to extract the gas structure of the lower protective layer, comprising the following steps:

[0097] S1, construction roadway

[0098] Construction protective layer working face incision 3, return air trough 4, belt conveyor trough 5, high-level high pumping lane 6;

[0099] In order to realize the mining of the protective layer working face, it is necessary to design the protective layer working face incision 3, the return air trough 4, the belt conveyor trough 5, and the high-level and high-extraction lane 6 in advance, and construct the high-level and high-extraction lane 6 in advance. In this example, the working face of the protective layer at the implementation site adopts an inclined strip arrangement, the working face of the protective layer is 200m long, the mining thickness of the protective layer is 4m, the distance between the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com