Three-dimensional mass center adjusting structure of solid rocket engine

A rocket engine and three-dimensional center of mass technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complicated design and processing, and a large number of counterweights, and achieve small space impact, less connections, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

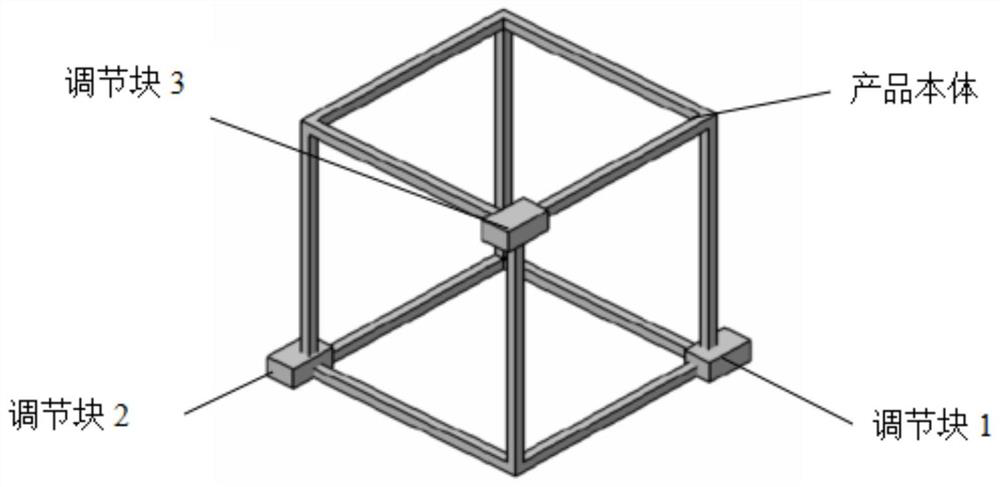

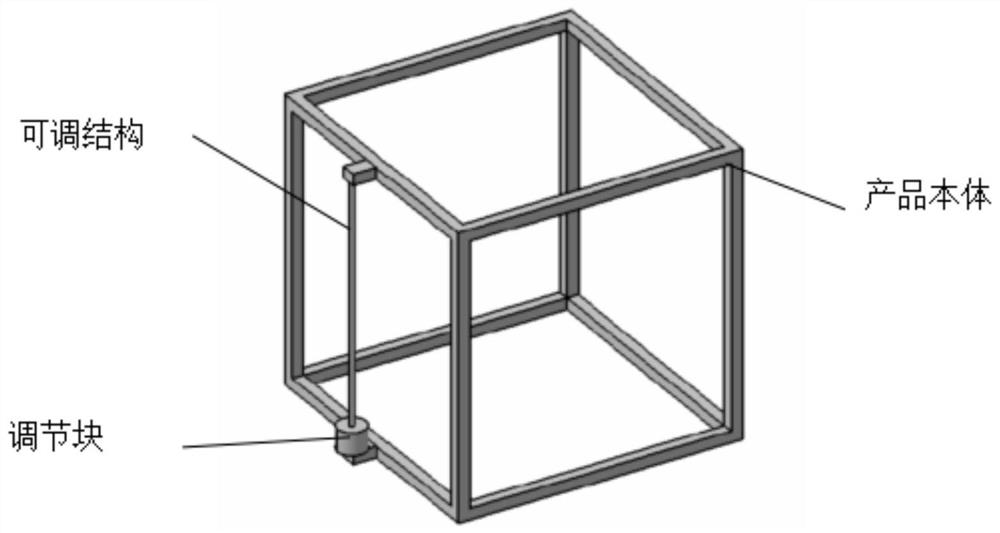

[0028] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

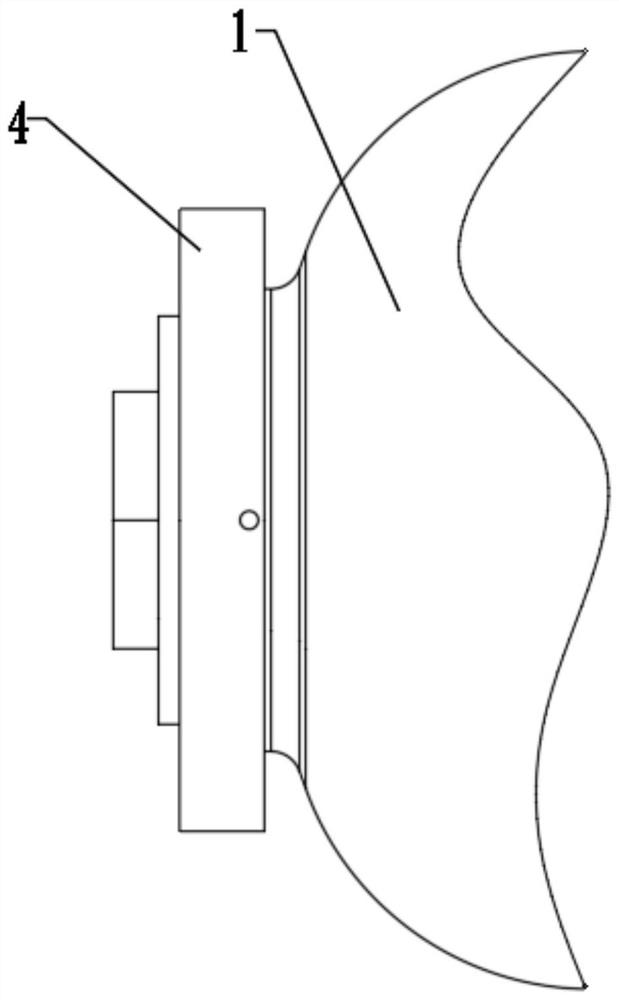

[0029] like Figure 1-5 As shown in the figure, the three-dimensional center of mass adjustment structure of the solid rocket motor provided by the present invention includes a support member 1, which is arranged at one end of the rocket motor casing 2; a limiting member 3 is arranged between the supporting member 1 and the rocket motor casing 2. A high and low step is formed between the support member 1 and the counterweight block 4, and the counterweight block 4 has an installation part 5 that cooperates with the support member and the limiting member; the counterweight block 4 is sleeved on the supporting member 1 and the limiting member 2 On the top, the counterweight 4 is connected with the limiter 3 .

[0030] like Figure 5 As shown in the figure, by forming a high and low step between the limiter 3 and the support 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com