Oil film sealing structure of valve

An oil film sealing and valve technology, applied in flange connection, passing components, mechanical equipment, etc., can solve the problems of difficult installation and disassembly of oil film sealing structure, affecting the convenient use of oil film sealing structure, and loosening of oil film sealing structure connection, etc. Increase the function of fixed socket, increase the fixed function, increase the effect of fixedness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

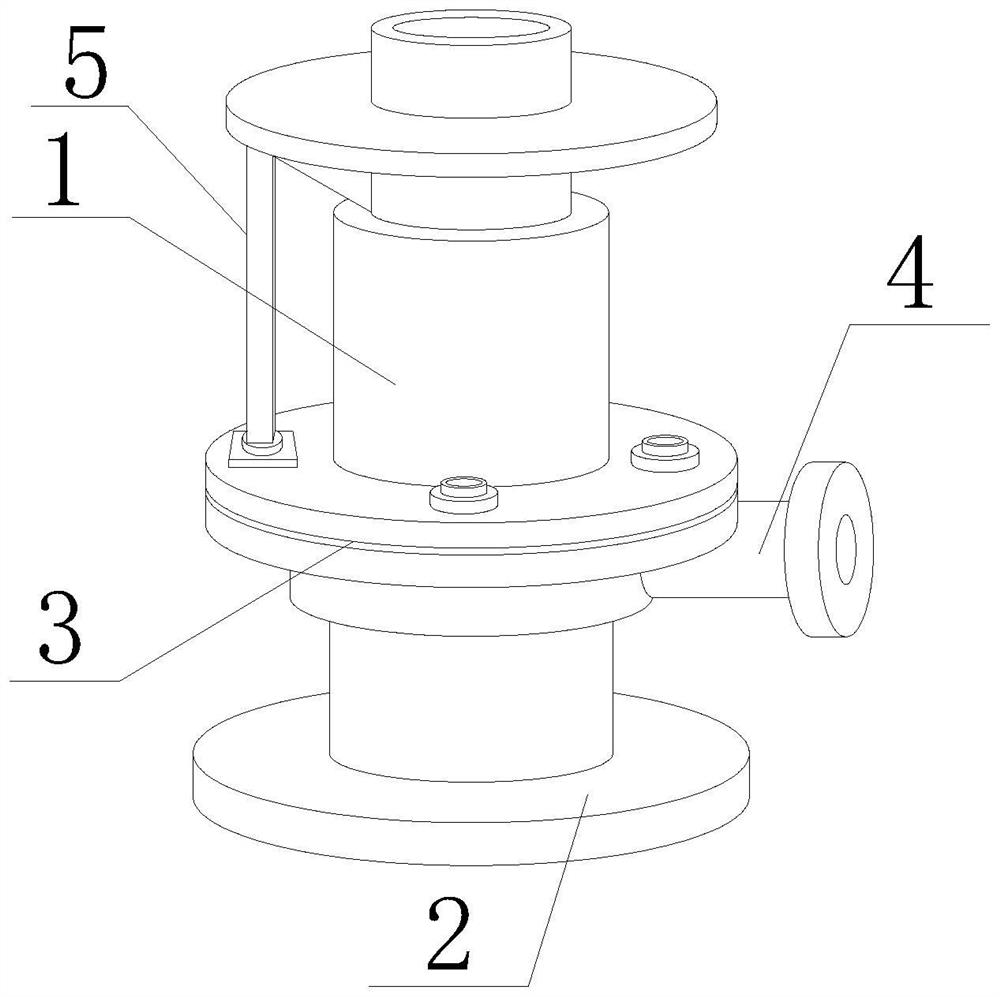

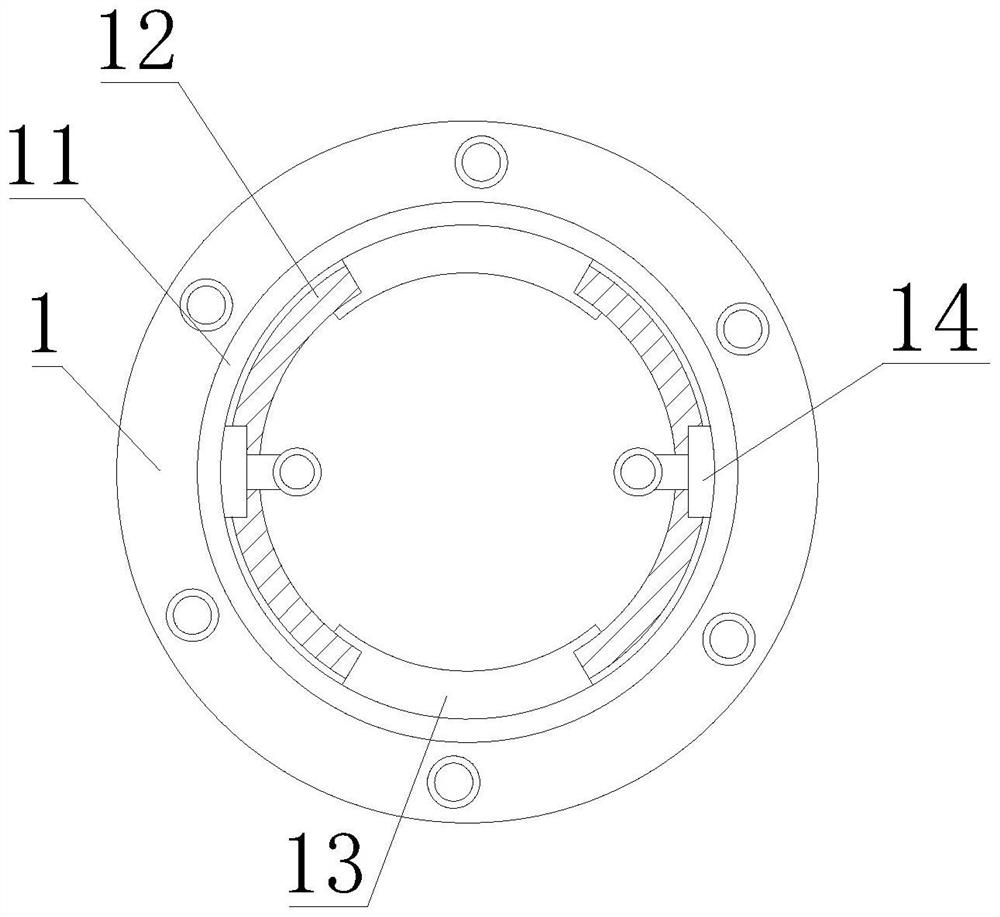

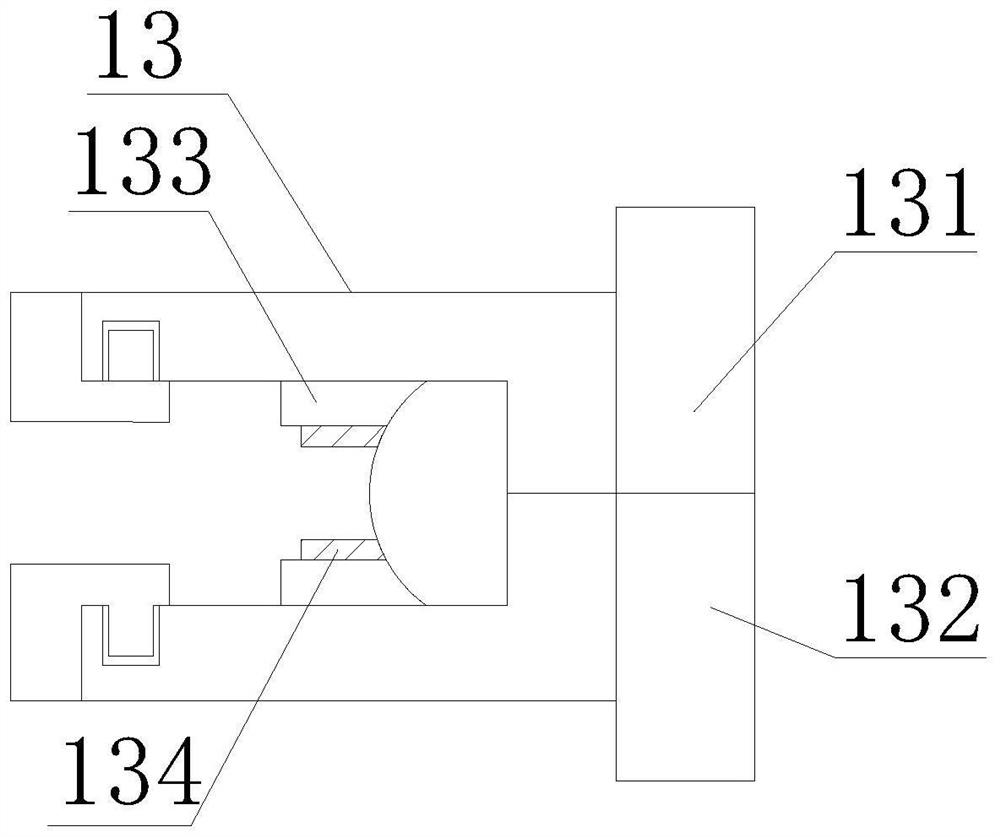

[0044] like Figure 1-8 As shown, the present invention provides an oil film sealing structure for a valve, including a valve body 1, a connecting base 2, a sealing flange 3 and a connecting pipe 4, the bottom of the valve body 1 is fixedly installed with the connecting base 2, and the middle part of the valve body 1 A sealing flange 3 is provided, a connecting pipe 4 is fixedly connected to one side of the bottom of the sealing flange 3, a connecting reinforcement rod 5 is fixedly installed on the top of the sealing flange 3, and a mounting block is fixedly installed inside the valve body 1. The mounting block A sealing film 12 is arranged on the outer side of the sealing film 12, a limit block 13 is arranged on the outer side of the sealing film 12, and a socket block 135 is movably installed on both sides of the limit block 13. The limit block 13 includes an upper card board 131. The plug board 1311 is fixedly installed, the bottom of the plug board 1311 is provided with a ...

Embodiment 2

[0047] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a fixed baffle 14 is fixedly installed on the top of the sealing membrane 12, and one end of the fixed baffle 14 is fixedly installed on the inner wall of the valve body 1 , the bottom of the fixed baffle 14 is provided with a moving slot 141, the interior of the moving slot 141 is provided with a telescopic column 142, the other end of the telescopic column 142 is fixedly installed with a moving block 143, and the bottom of the moving block 143 is fixedly installed with a pressing block 144, the pressing block A friction pad is fixedly installed on the side of 144 close to the inner wall of the valve body 1 .

[0048] In this embodiment, when the sealing film 12 cooperates with the limiting block 13 to be fixedly installed, the telescopic column 142 is telescopically moved to drive the moving block 143 to move inside the moving groove 141 , so that ...

Embodiment 3

[0050] like Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top of the fixed plate 14 is provided with a fixed pressure ring 11, and the outer side of the fixed pressure ring 11 is fixedly installed on the inner wall of the valve body 1, The bottom of the fixed pressure ring 11 is provided with a lifting rod 111, the bottom of the lifting rod 111 is provided with a mounting ring 112, the bottom of the mounting ring 112 is fixedly mounted with a squeeze pad 113, and the inside of the squeeze pad 113 is fixedly mounted with a buffer pressure pad 1131, A rubber pad 1132 is fixedly installed at the bottom of the buffer pressure pad 1131 , and friction particles are fixedly installed at the bottom of the rubber pad 1132 .

[0051] In this embodiment, when the sealing film 12 is sealed and fixed, it cooperates with the lifting rod 111 to telescopically move, and drives the mounting ring 112 to move and squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com