Machine tool processing energy efficiency modeling system and method based on support vector regression and t test

A technology of support vector regression and test statistics, applied in the fields of electronic engineering and computer science, it can solve the problems of reduced prediction accuracy, inability to dynamically change the state of the bed, lack of generality of modeling methods, etc. The effect of prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

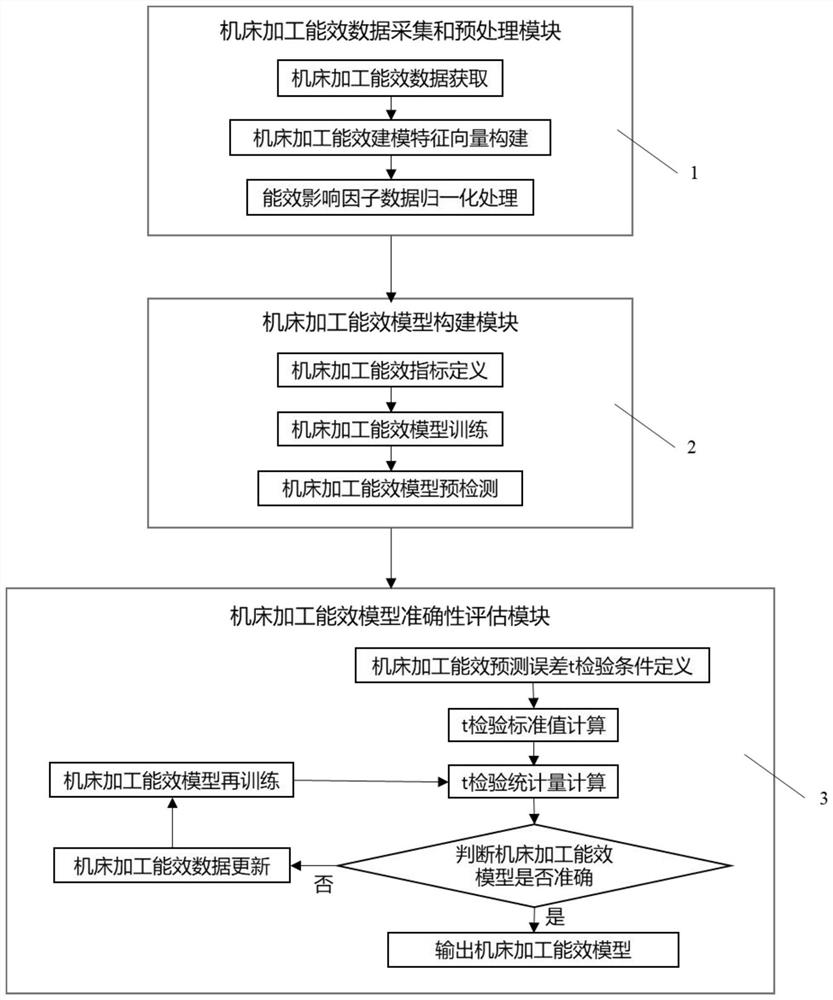

[0043] like figure 1 As shown, the specific embodiment of the system of the present invention is as follows:

[0044] figure 1 The 1 in the 1 represents the machine tool processing energy efficiency data acquisition and preprocessing module. The specific implementation of this module is as follows:

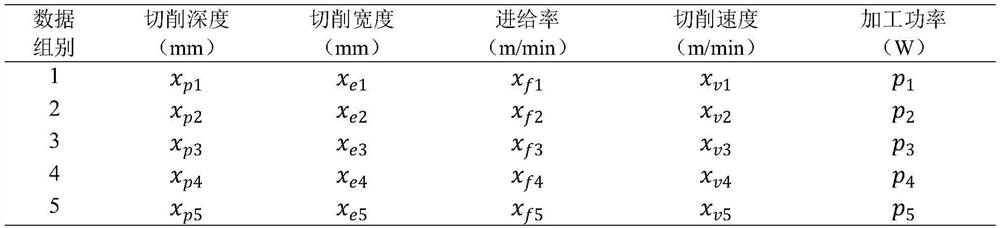

[0045] (11) Acquisition of machine tool processing energy efficiency data: Obtain the machine tool processing energy efficiency influencing factor data from the machine tool processing process parameters, including cutting depth, cutting width, cutting speed, and feed rate; and by monitoring the real-time state of the machine tool processing process, obtain the machine tool processing energy efficiency The machining power P of the machine tool corresponding to the influence factor;

[0046] (12) Construction of eigenvectors of machine tool machining energy efficiency modeling: Based on the selected influence factors of machine tool machining energy efficiency, construct machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com