A stone cutting device and its working method

A stone cutting and working technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of exposed cutter heads, user damage, etc., and achieve the effect of avoiding safety hazards and overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

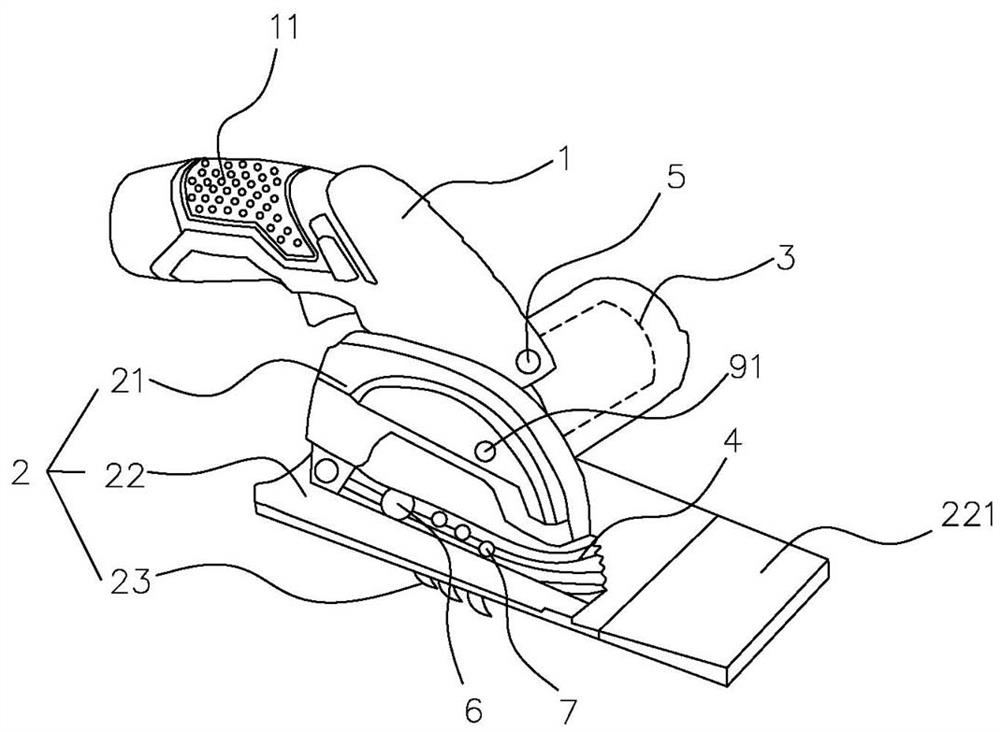

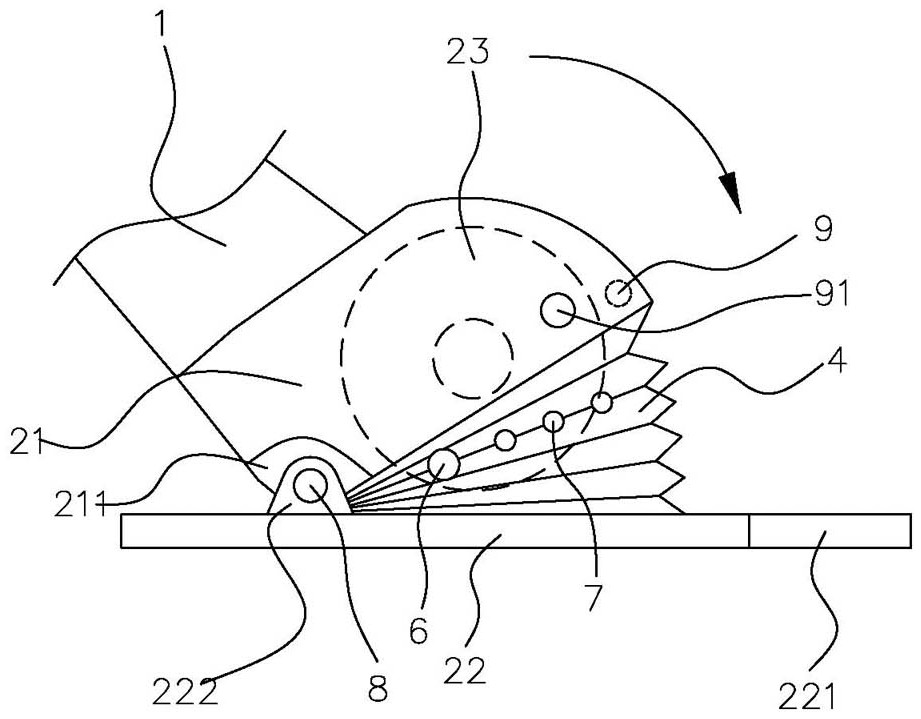

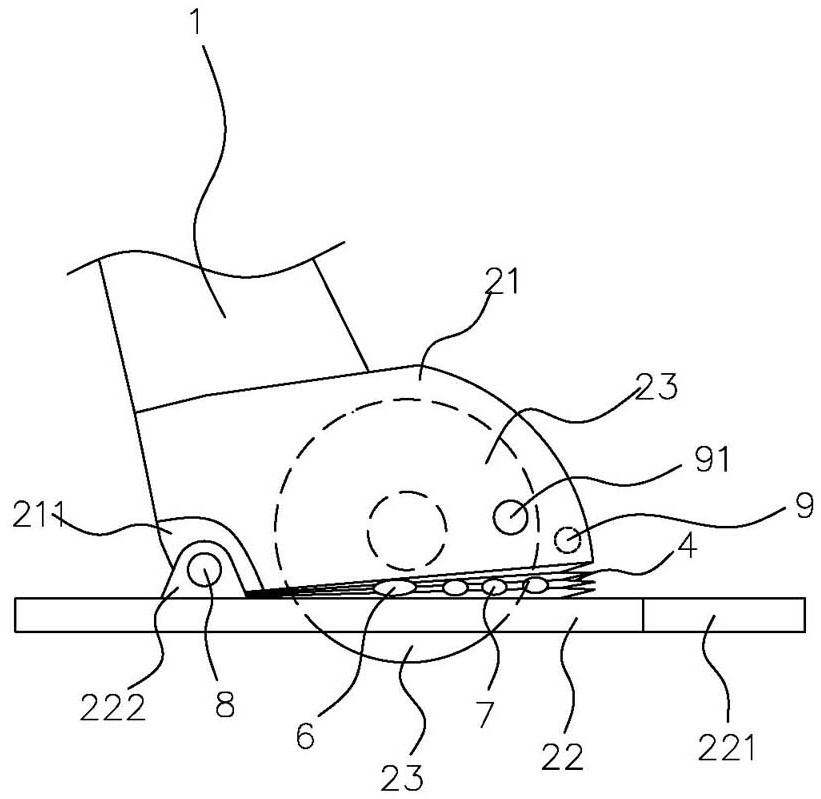

[0052] refer to Figure 1 to Figure 5 , Figure 7 to Figure 8 , the first embodiment proposes a stone cutting device, the stone cutting device includes:

[0053] a housing 1, a handle 11 is integrally formed on the housing 1;

[0054] Cutting mechanism 2, the cutting mechanism 2 includes a stone cutting blade 23, a protective cover 21 and a support plate 22, the protective cover 21 is fixed on the housing 1, and the stone cutting blade 23 is placed on the protective cover 21, two-thirds of it is surrounded by the protective cover 21, the protective cover 21 and the support plate 22 are rotatably connected by a rotating mechanism, specifically, the two are rotatably connected at one end of the handle 11, and the two are far away from the handle. Open and close one end of 11 freely (refer to figure 2 ); a flexible blocking wall 4 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com