Efficient filtration and separation treatment equipment for textile wastewater

A textile wastewater and high-efficiency filtration technology, which is applied in the direction of textile industrial wastewater treatment, filtration treatment, centrifugal separation water/sewage treatment, etc., can solve the problems that the filtering effect needs to be improved, the filter net is easy to be blocked, and the replacement is inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

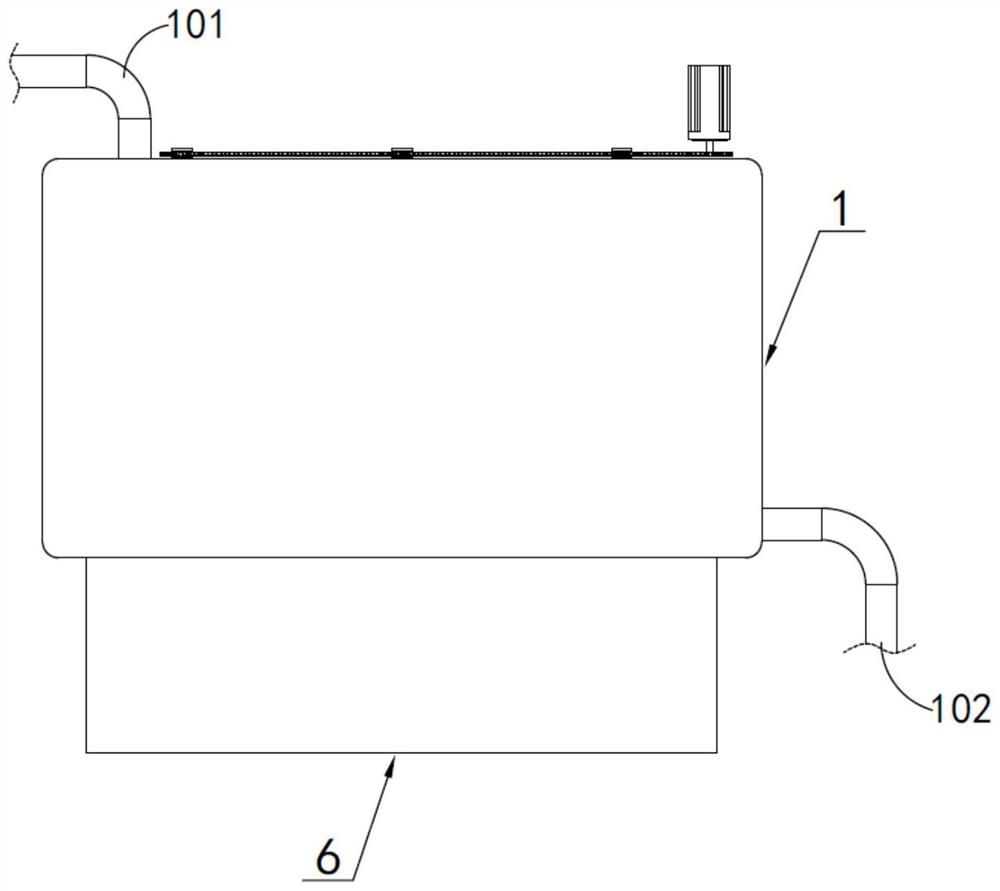

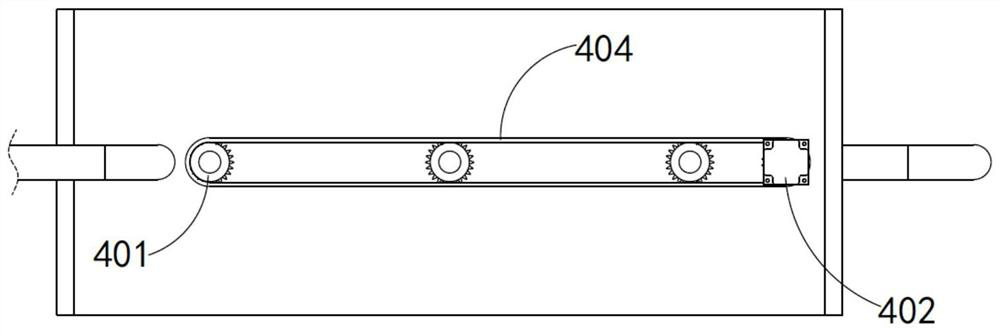

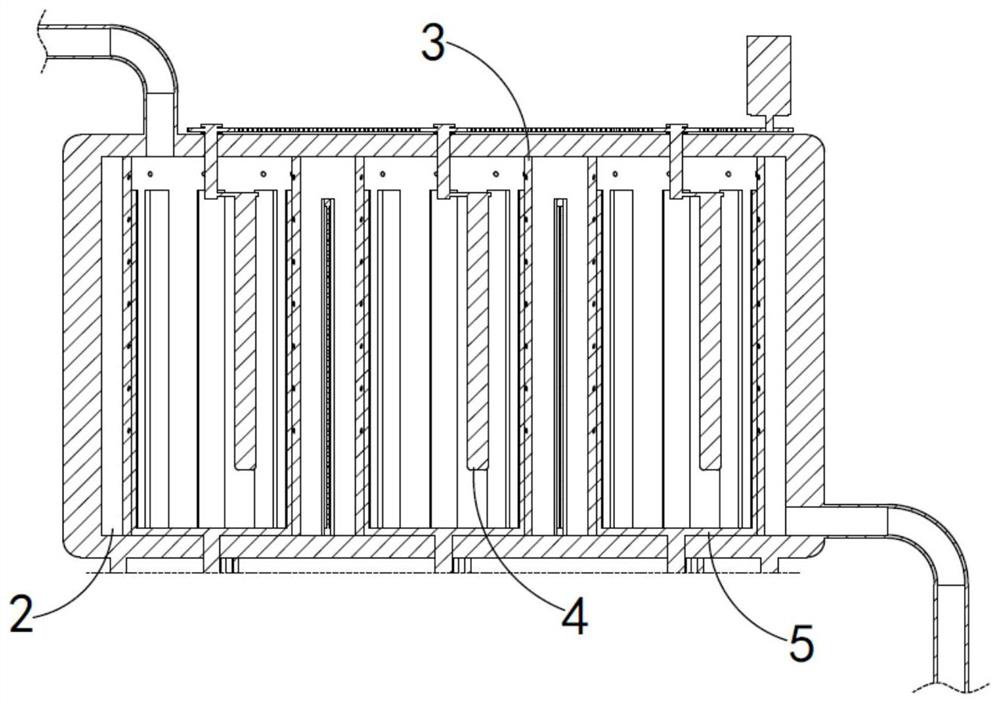

[0031] like Figure 1 to Figure 9 As shown, the embodiment of the present invention provides a high-efficiency filtration and separation treatment equipment for textile waste water, including a filter box 1, a plurality of filter cavities 2 are arranged inside the filter box 1, and a separation cylinder 3 and a filter cavity 2 are arranged in the filter cavity 2. The rotating stirring blade 4 is matched with the separation drum 3. The separation drum 3 is used to accommodate the textile waste water and agitate and rotate the textile waste water by rotating the stirring blade 4, so that the impurities in the textile waste water are gathered in the center of the vortex. A number of discharge water holes 301 and a jacking control ring 5 are respectively provided, and the jacking control ring 5 keeps the liquid level of the textile waste water in the separation cylinder 3 always at the same height as the uppermost water outlet hole 301 in the vertical direction by jacking up. Duri...

Embodiment 2

[0043] as attached Figure 4 As shown in the figure, the same or corresponding parts as in the first embodiment are marked with the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment The difference lies in that a filter screen 201 is also arranged between the filter chambers 2, and the filter screen 201 is used for the secondary filtering of the separated textile waste water discharged between the separation cylinders 3, and the rear side of the filter box 1 corresponds to each filter chamber 2 is also provided with a cleaning door, and opening the cleaning door can clean the solid waste remaining in the separation cylinder 3 after filtration and separation.

[0044] The working principle of the present invention is as follows:

[0045] The textile waste water enters the separation cylinder 3 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com