Silicon wafer cutting machine with cutting fluid recycling function

A cutting fluid and cutting machine technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of wasting cutting fluid, ineffective recycling of cutting fluid, and lack of cutting fluid recovery devices. The effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

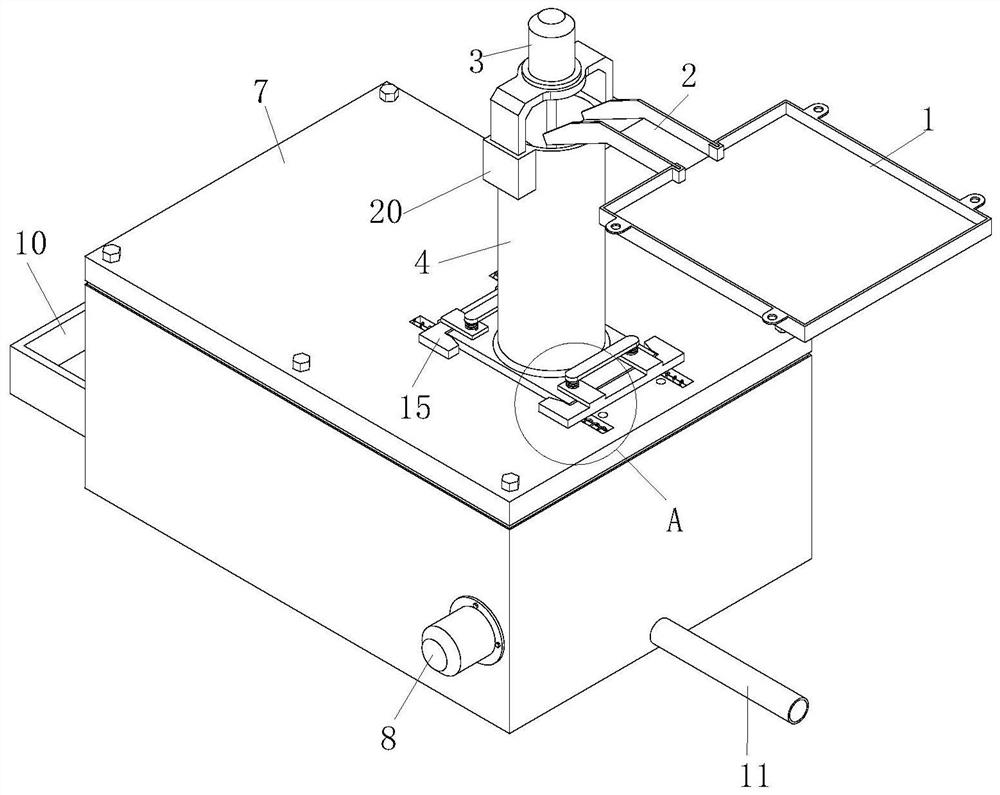

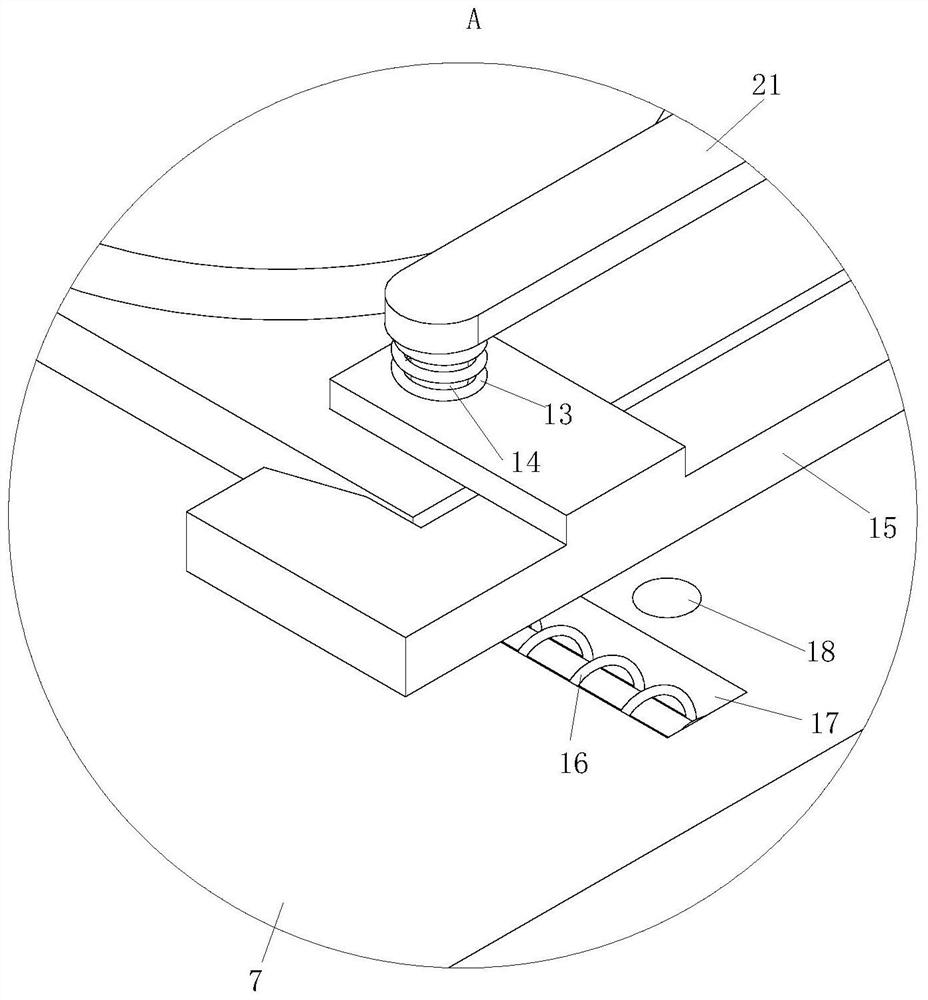

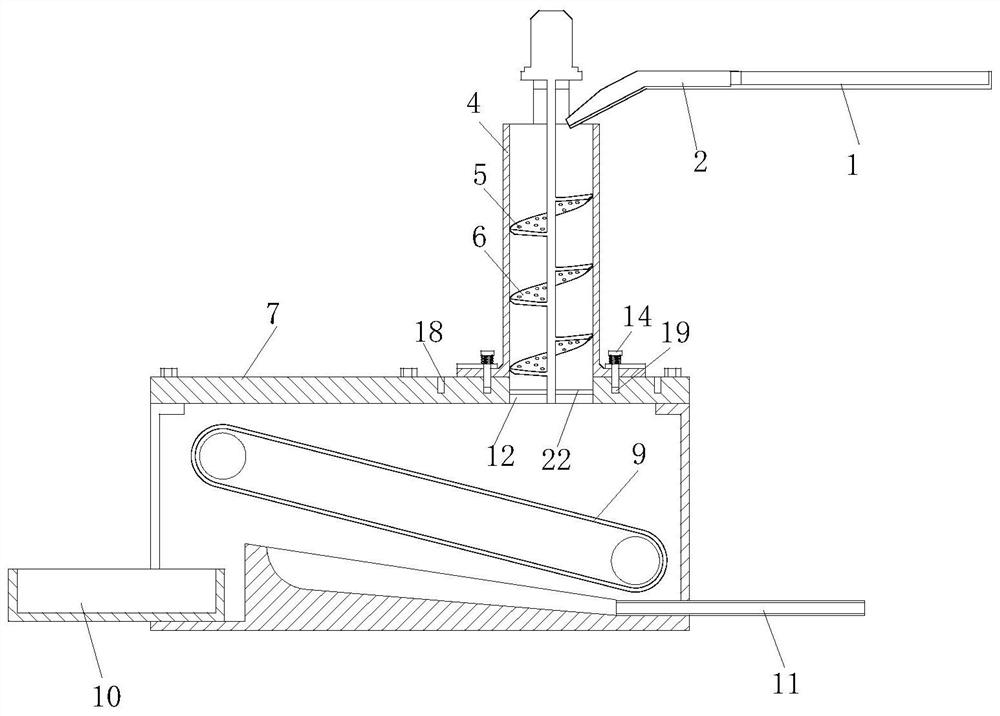

[0023] refer to Figure 1-3 , a silicon wafer cutting machine with cutting fluid recovery function, comprising a deflector 1 for collecting cutting fluid, a diversion groove 2 is provided on one side of the deflector 1, and the outlet end of the diversion groove 2 is provided with a The primary filter mechanism for cutting fluid recovery, the primary filter mechanism is used to filter out particulate debris in the cutting fluid, and a secondary filter mechanism for cutting fluid recovery is provided below the primary filter mechanism, and the secondary filter mechanism is used to filter out the cutting fluid. The powdery debris and the primary filter mechanism and the secondary filter mechanism are connected by a quick release mechanism.

[0024] The primary filter mechanism includes a No. 1 motor 3, a tower cylinder 4 and a spiral blade 5; the lower end of the tower cylinder 4 is connected to the secondary filter mechanism connected to the tower cylinder 4 through a quick rel...

Embodiment 2

[0032] refer to Figure 4 , Comparative Example 1, as another embodiment of the present invention, wherein the edge of the guide plate 1 is provided with connecting ears 23, the guide plate 1 is fixed under the silicon wafer cutting machine through the connecting ears 23, 23. It is convenient to fix the deflector 1 .

[0033] Working principle: The cutting fluid flows into the tower 4 from the deflector 1 and the diversion groove 2, and the No. 1 motor 3 is rotated by the electric spiral blade 5. During the rotation, the cutting fluid is stirred and filtered. One is to improve the filtration efficiency. The second is to prevent debris from blocking the overflow hole 6. The debris in the cutting fluid that can pass through the overflow hole 6 directly falls into the box 7, and the debris that fails to pass through the overflow hole 6 is filtered in the spiral blade. 5. At this time, the primary filtration of the cutting fluid is realized, that is, the large particles of debris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com