Lower chord bending tubular joint of inclined truss of large-span roof system

A technology of intersecting nodes and large spans, applied in the field of trusses, can solve the problems of interfering with the connection between web members and chord members, large loads, affecting the strength of steel plates, etc., to improve structural strength and stability, reduce welding difficulty, increase The effect of external surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

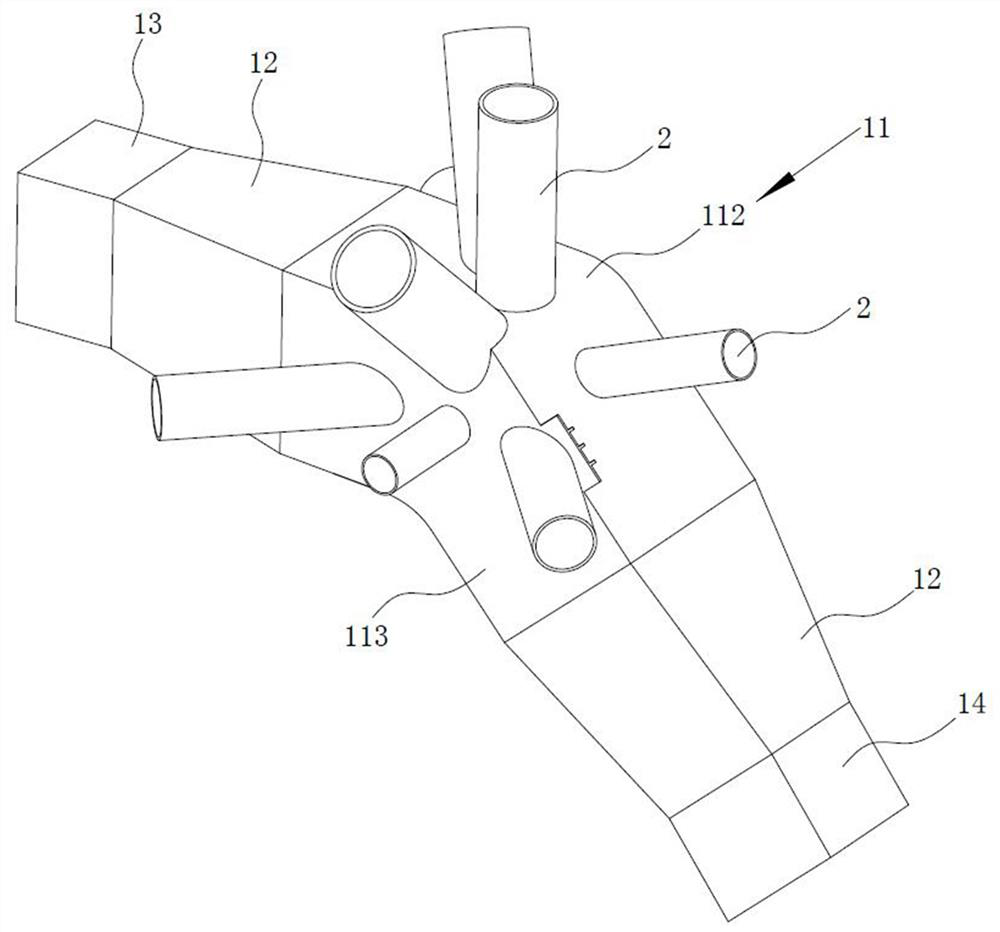

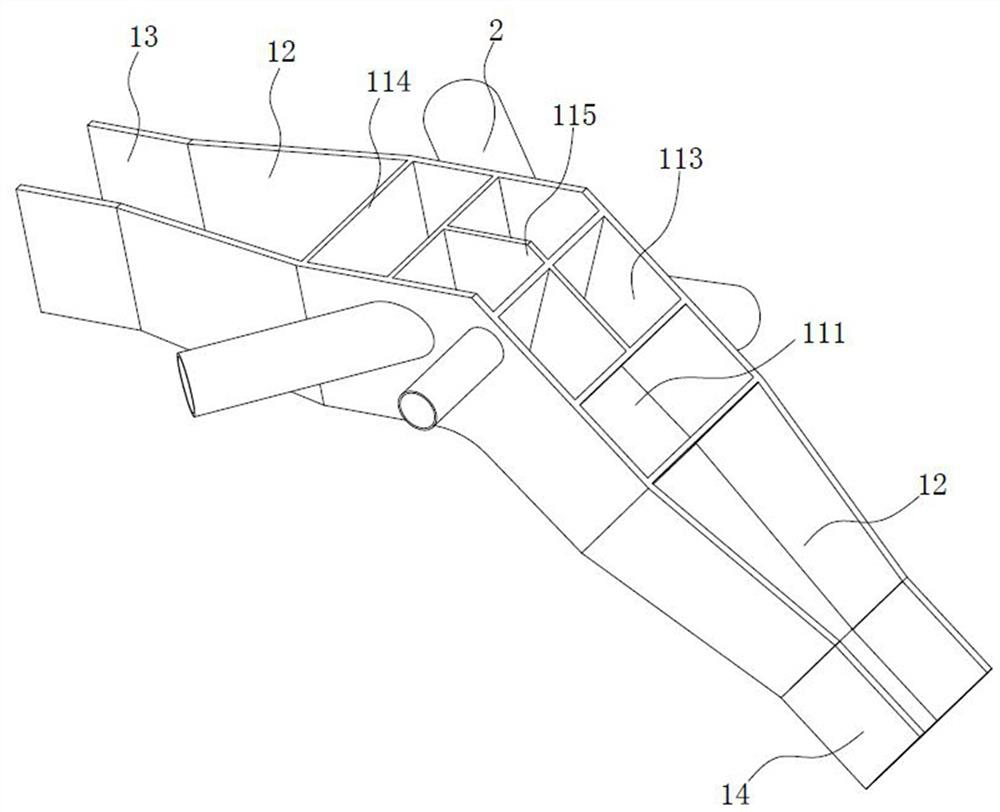

[0038] refer to figure 1 and figure 2 , the lower chord bending intersection nodes of the large-span roof system inclined trusses include chords and webs 2 . The chord includes a first chord 13, a second chord 14 and a bending section 11. The bending section 11 is arranged between the first chord 13 and the second chord 14, and between the first chord 13 and the bending section A connecting segment 12 is welded between the 11 and between the second chord 14 and the bending segment 11 . The web rods 2 are welded on the outside of the bending section 11 , and the extension lines of the axes of all the web rods 2 intersect at a point on the axis of the bending section 11 to avoid eccentric stress on the bending section 11 .

[0039] refer to figure 1 and figure 2 , the section of the bending section 11 is a box-shaped section, the bending section 11 includes an inner bending plate 111, an outer bending plate 112 and two connecting plates 113, the inner bending plate 111 a...

Embodiment 2

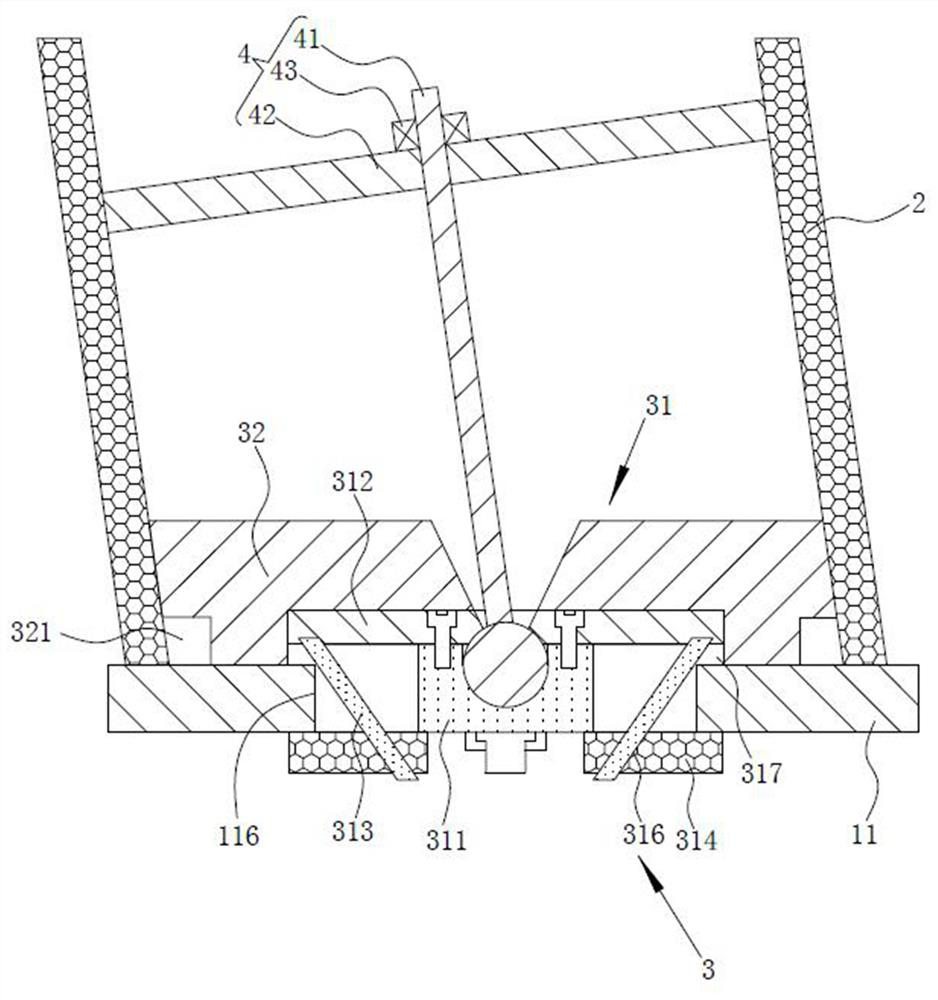

[0043] refer to image 3 The difference between this embodiment and the first embodiment is that a reinforcing device 3 and a preloading device 4 are arranged at the connection between the web rod 2 and the chord rod.

[0044] refer to image 3 and Figure 4 , the reinforcing device 3 includes a connecting head 31 that is clamped on the bending section 11 and a reinforcing block 32 that is detachably connected to the connecting head 31 . A mounting hole 116 for mounting the connector 31 is opened on the bent section 11 . The connecting head 31 includes a connecting seat 311 and a fixing cover 312, and the connecting seat 311 is inserted into the mounting hole 116; a positioning outer edge 317 is integrally formed on the outer peripheral side of the connecting seat 311, and the positioning outer edge 317 abuts on the outside of the bending section 11, It is used to prevent the connecting seat 311 from falling into the bending section 11 .

[0045] The fixing cover 312 is bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com