Automatic hydrological flood mark monitoring device suitable for flood disaster-prone areas

A monitoring device and multi-generation technology, which are applied in measurement devices, climate change adaptation, and components of color TVs, etc., can solve the problems of being easily affected by objective conditions and poor accuracy, and achieve easy popularization and use, convenient operation, and reduced use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

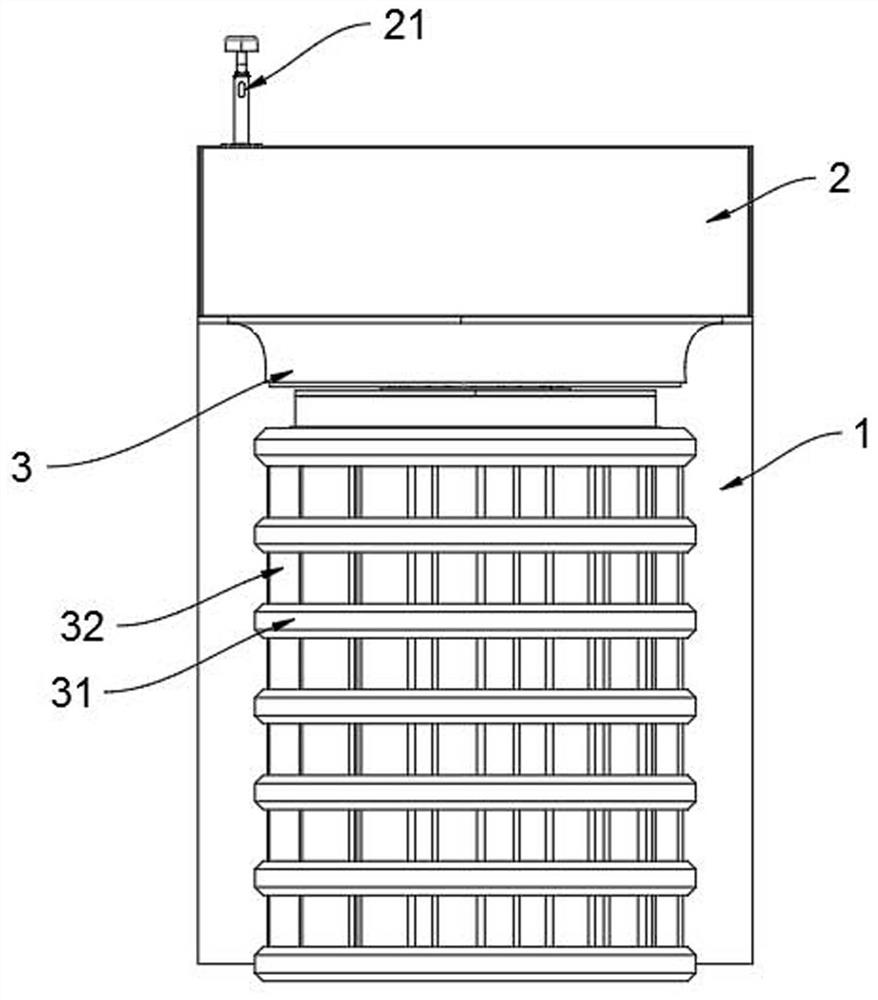

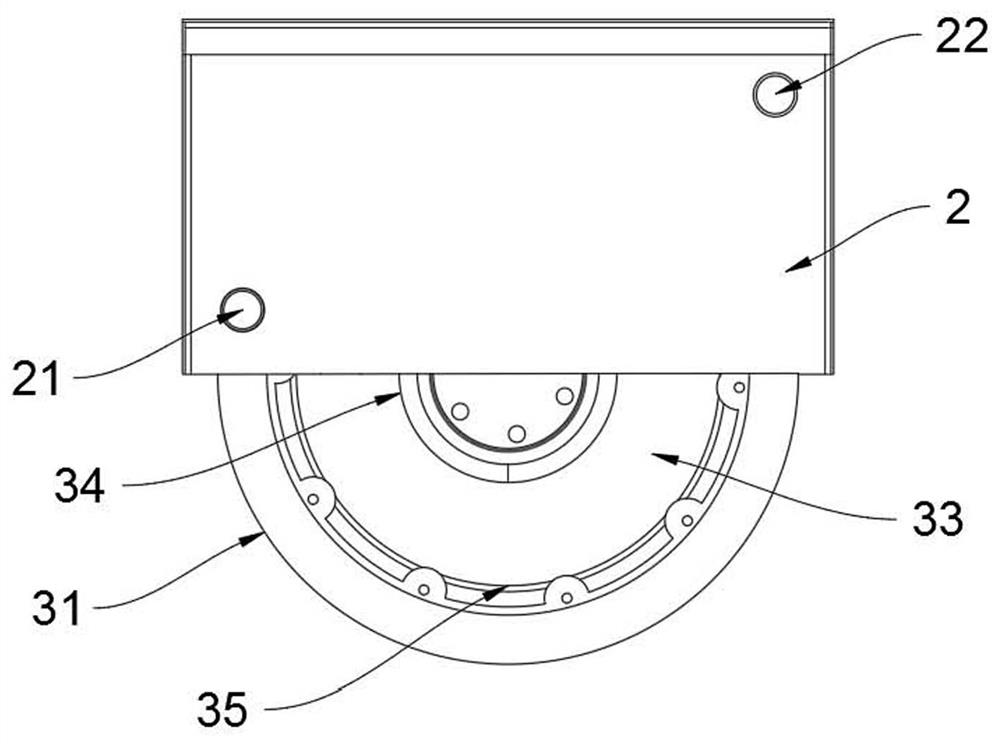

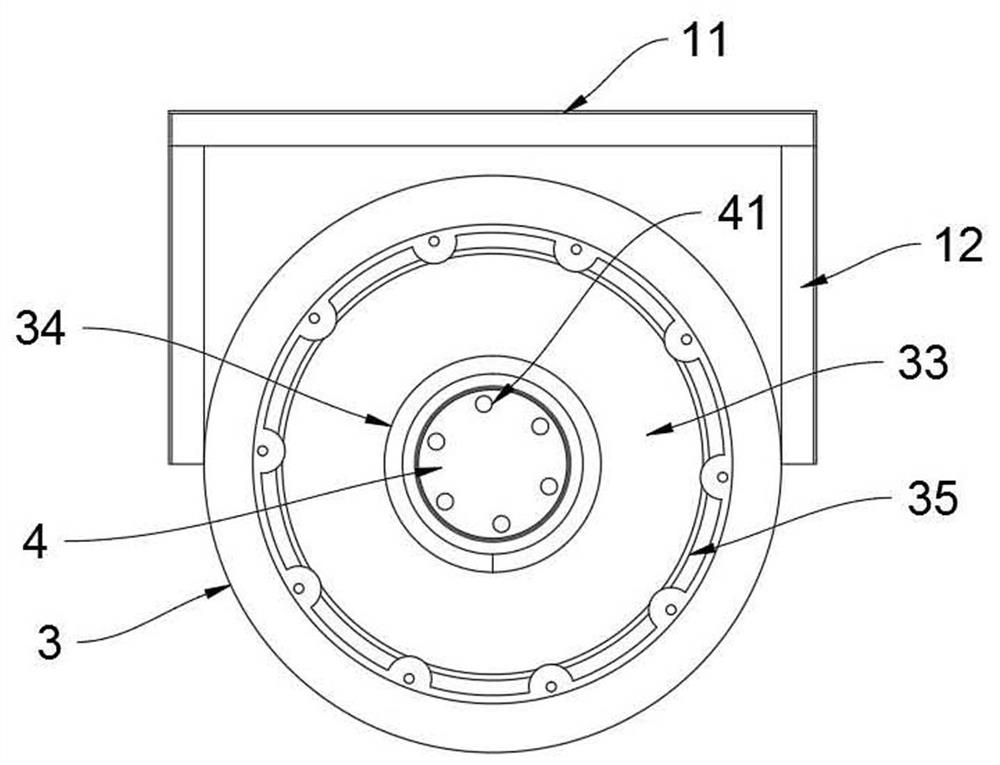

[0029] as Figures 1 through 9As shown, an automated hydrological flood monitoring device suitable for flood-prone areas, comprising an installation bracket 1, an installation bracket 11 comprising a mounting plate 11 and several groups of vertically arranged connecting arms 12, one end of the connecting arm 12 is fixedly connected to the mounting plate 11, the surface of the connecting arm 12 is fixedly connected to the flood trace box 3, the flood trace box 3 includes a spacer 31, several groups of connection arms 12 and the spacer 31 is fixedly connected, the interval frame 31 is actively connected to the transfer pipe member 32, and the surface of the pipe transfer member 32 is provided with a guide plate, Water flow, driving the rotation pipe fittings 32 rotation, the center of the flood trace box 3 is provided with a flood trace tube 34, the upper and lower ends of the flood trace pipe 34 are through, the water enters the flood trace pipe 34 from the bottom of the flood trace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com