Energy-saving component

A technology of components and driving parts, applied in electrical components, mechanisms for generating mechanical power, electromechanical devices, etc., can solve problems such as small torque, motor environment restrictions, and difficulty in effectively improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

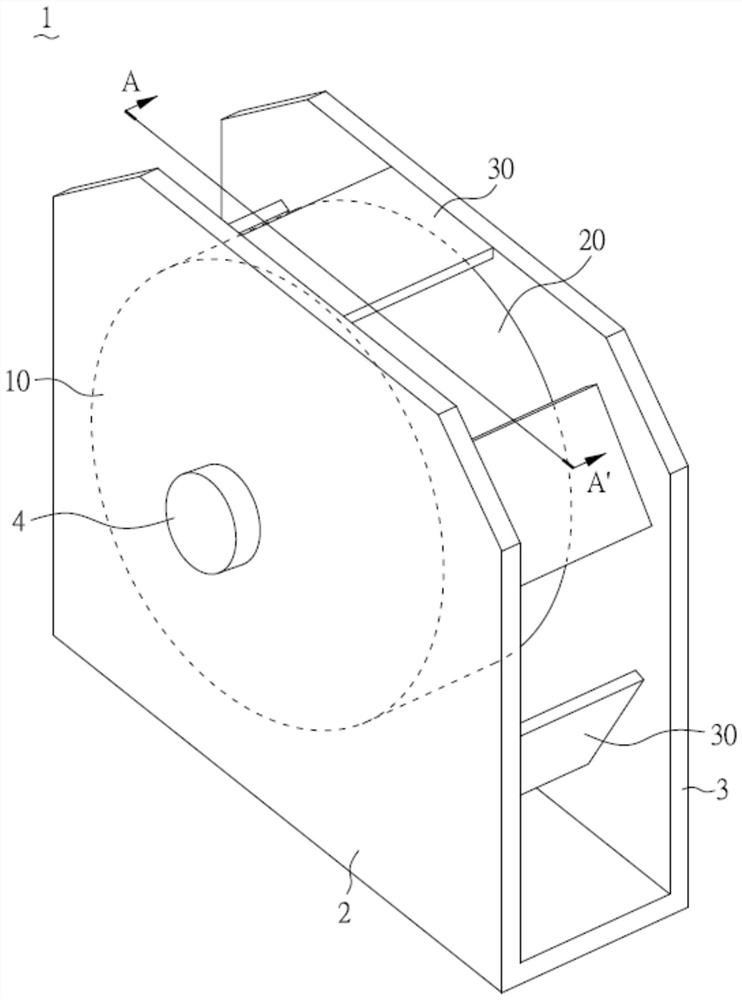

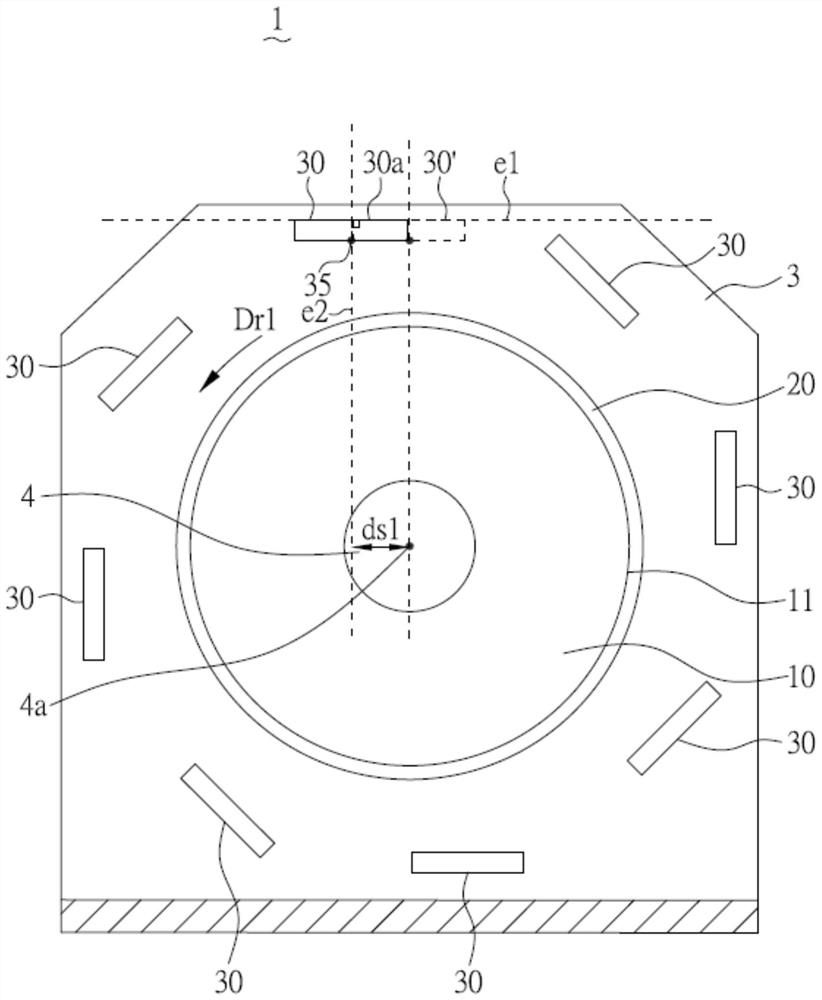

[0061] figure 1 A perspective view of the energy-saving member (1) of Example 1 of the present invention is shown. figure 2 The energy-saving member (1) of Example 1 of the present invention is shown along figure 1 A cross-sectional view of the A-A' line.

[0062] like figure 1 and figure 2 As shown, in the energy-saving component (1) for a power source of this embodiment, the energy-saving component (1) includes a first side plate (2), a second side plate (3), an axis (4a), an axis A part (4), an energy-saving runner (10), an outer surface (11), a permanent magnet (20) and a magnetic drive member (30). The energy-saving runner (10) is pivotally connected to the first side plate (2) and the second side plate (3) through the shaft portion (4), and has an outer surface (11), and the shaft portion (4) Connect the external rotating shaft (not shown in the figure), and drive the energy-saving runner (10) to rotate through the external rotating shaft (not shown in the figure)...

Embodiment 2

[0067] Fig. 4(A) shows a perspective view of the energy-saving member (1) of Example 2 of the present invention.

[0068] As shown in FIG. 4(A), the structure of this embodiment is similar to that of Embodiment 1, and has similar features and effects to Embodiment 1, so it will not be repeated here. The difference from Embodiment 1 is that this embodiment The permanent magnet (20) of the embodiment is a ring-shaped structure, and two permanent magnets (20) parallel to each other are arranged on the outer surface (11) of the energy-saving runner (10), but it is not limited to this; In an embodiment, a plurality of permanent magnets (20) parallel to each other can be arranged on the outer surface (11) of the energy saving wheel (10), as long as the outer surface (11) of the energy saving wheel (10) is sufficient to accommodate. In addition, as long as it is reasonable, the details and features of each embodiment can also be arbitrarily combined.

Embodiment 3

[0070] Fig. 4(B) shows a perspective view of the energy-saving member (1) of Example 3 of the present invention.

[0071] As shown in FIG. 4(B), the structure of this embodiment is similar to that of Embodiment 1, and has similar features and effects as Embodiment 1, so it will not be repeated here. The difference from Embodiment 1 is that this embodiment The permanent magnet (20) of the embodiment is composed of a plurality of micro-magnets arranged along a specific direction, and is also arranged on the outer surface (11) of the energy-saving runner (10), but is not limited thereto. In addition, as long as it is reasonable, the details and features of each embodiment can also be arbitrarily combined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com