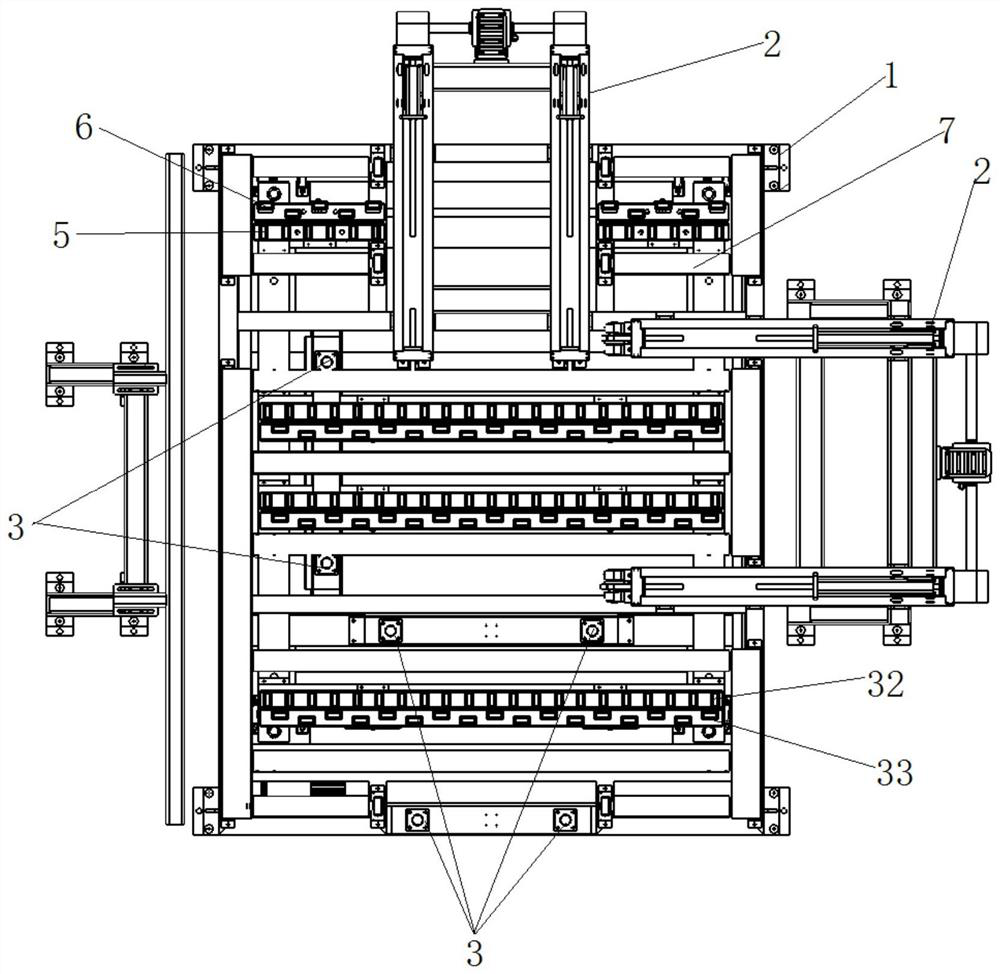

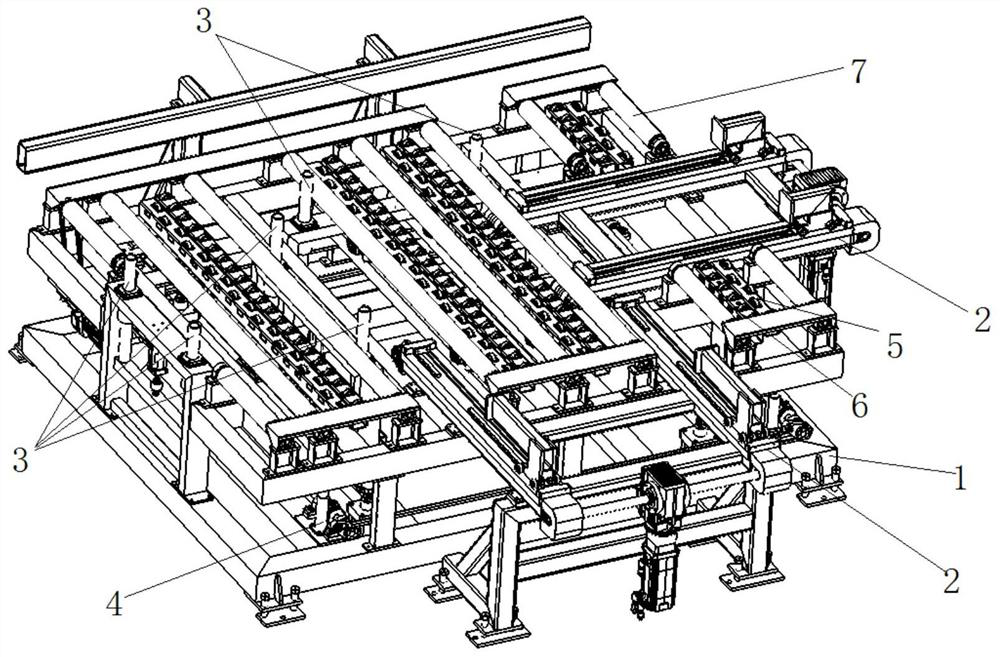

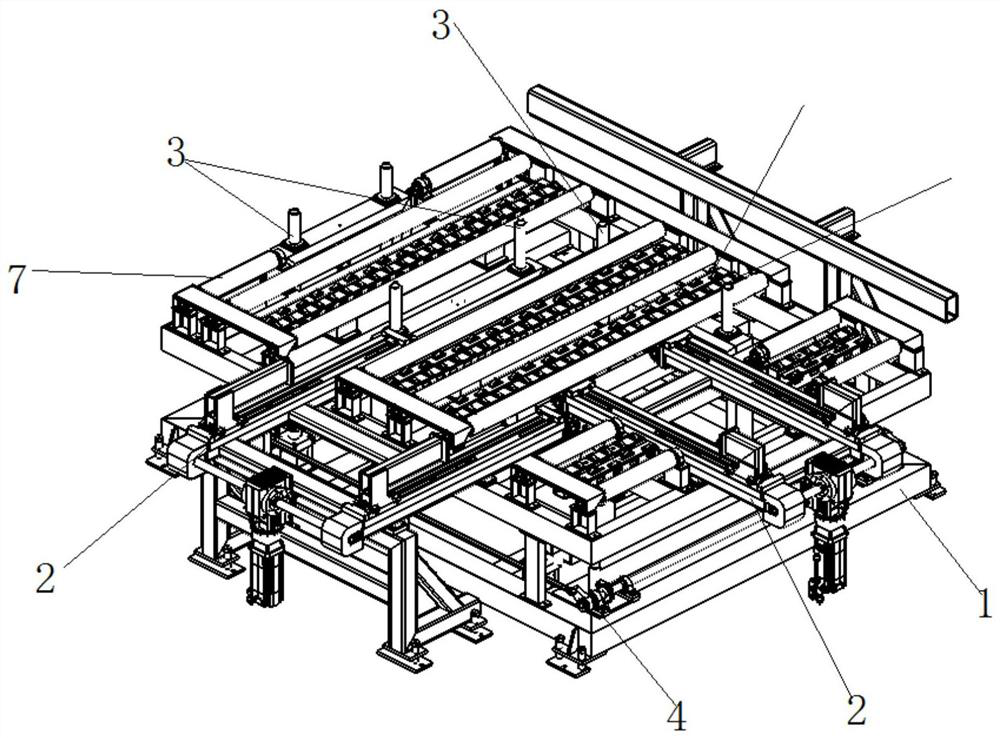

Plate arranging device

A sheet, structured technology for transport and packaging, conveyor items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Further, it is necessary to automatically lower the ribs 3 of the regular frame. The specific process is as follows: the rib cylinder 28 stretches out, drives the rib connecting rod 25 to move downward, and the rib connecting rod 25 drives the rib retaining rod 24 to move on the rib bearing. 23 and move downwards, and the sidewall bar 24 moves downwards so as to be level with the level of the sidewall installation frame 22, and complete the descending action of the automatic sidewall.

[0042] Further, the action 4 of the conveying roller assembly conveys the sheet from the sheet regularizing device. The specific process is as follows: the motor 52 is started and connected through the transmission belt 53 to drive the movement of the conveying roller 51, and the transmission belt 52 installed between the conveying rollers 51 drives the adjacent The conveying roller 51 moves to convey the plate out of the plate regularizing device.

[0043] The basic principles, main fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com