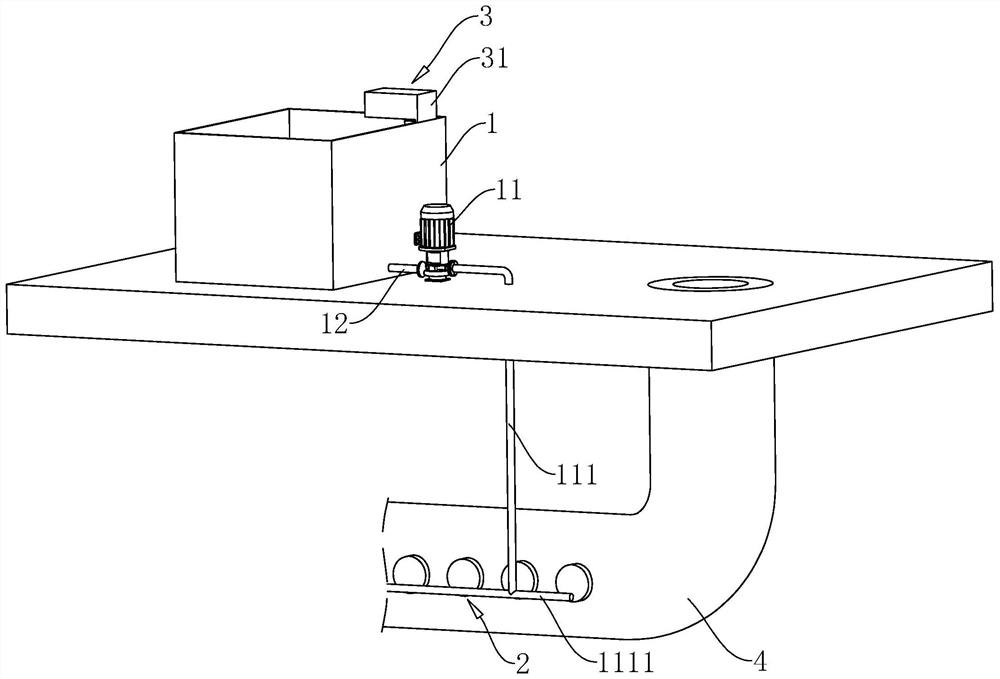

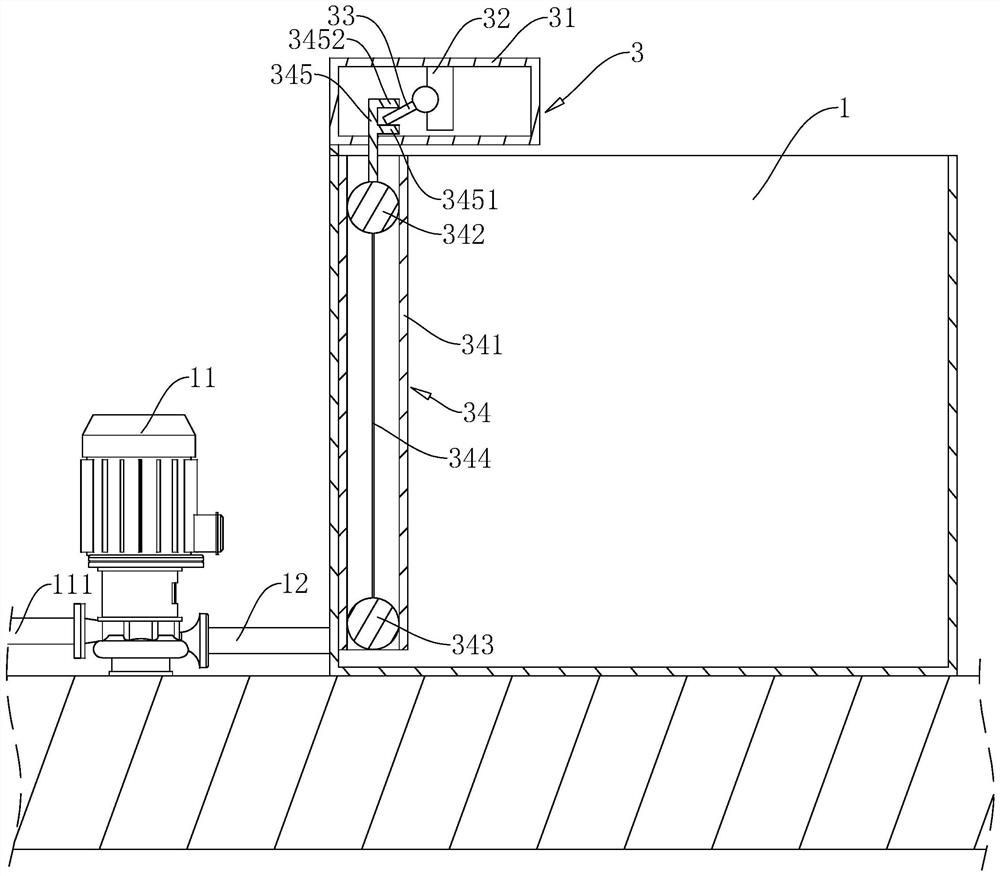

Pipeline dredging equipment for water conservancy project and using method

A technology for water conservancy projects and pipelines, which is used in the cleaning of sewer pipes, waterway systems, and general water supply conservation to achieve the effects of reducing accumulation, reducing silt, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

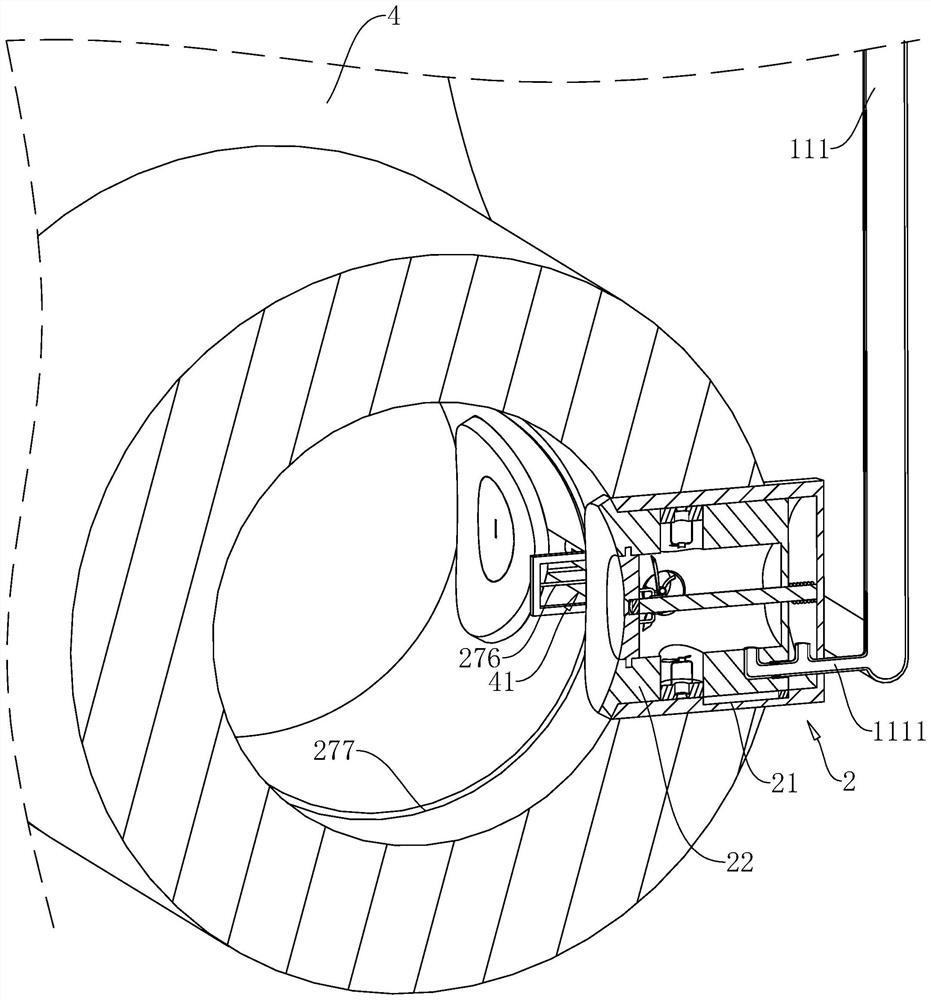

[0047] After the water supply branch pipe 1111 introduces the water flow into the cavity 212, the movable cylinder 22 drives the stop block 222 to slide toward the inside of the pipe 4, and when the stop block 222 touches the groove end wall of the chute, the second rotating disk 25 is fully extended and fixed. The water flow in the cylinder 21 and the movable cylinder 22 is sprayed from the first water spray hole 231 and the second water spray hole 251 towards the inner wall of the pipeline 4, which increases the spray range, helps to further reduce the spray dead angle, and further improves the performance of the The dredging effect of the pipeline 4 is conducive to further reducing the possibility of the pipeline 4 being blocked due to silt accumulation. After the water pump 11 stops, the spring 2112 pulls the movable cylinder 22 to reset, and the water in the cavity 212 flows back into the water supply branch pipe 1111.

[0048] refer to Figure 5 and Figure 6Conduit 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com