Molded case circuit breaker with quick installation structure

A technology of molded case circuit breaker and installation structure, which is applied to circuits, emergency protection devices, parts of protection switches, etc., to achieve the effects of good stability, easy disassembly and maintenance, and simple installation and disassembly processes.

Active Publication Date: 2022-06-10

重庆砼山德机械有限公司 +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the deficiencies of the prior art, the present invention provides a molded case circuit breaker with a quick installation structure, which solves the problem of installing the molded case circuit breaker on a suitable position, but the molded case circuit breaker requires regular maintenance, and if it is fixed by bolts, the process of disassembling or reinstalling the molded case circuit breaker is cumbersome, which will increase the pulling strength of the staff and reduce the The problem of maintenance efficiency of molded case circuit breakers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

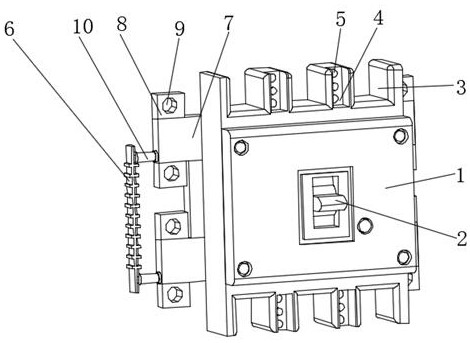

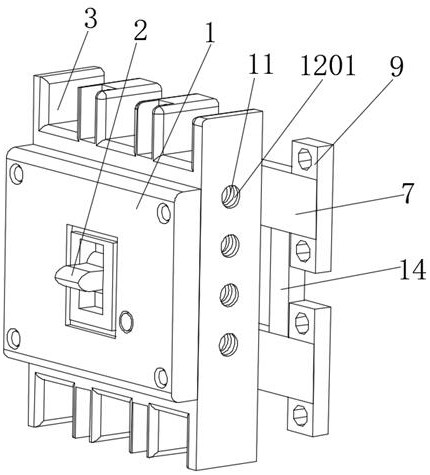

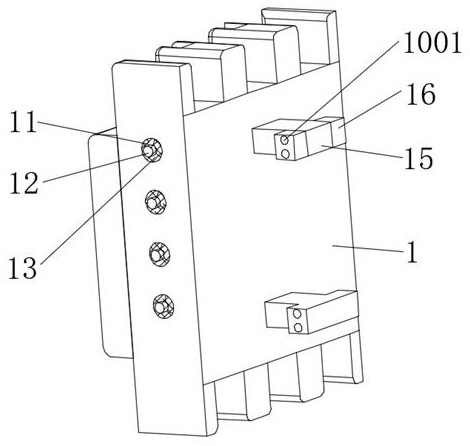

The invention provides a molded case circuit breaker with a rapid installation structure, and relates to the technical field of molded case circuit breakers, the molded case circuit breaker comprises a molded case circuit breaker body, the front surface of the molded case circuit breaker body is provided with an operation handle, the rear surface of the molded case circuit breaker body is provided with two supporting plates, and a clamping block is installed in a clamping groove through a fixing assembly. According to the molded case circuit breaker, the first sliding plate is pulled to enable the side plate to move backwards, and when the first sliding plate moves, the second sliding plate and the first sliding plate can be driven to move in the opposite directions, so that the molded case circuit breaker is prevented from being damaged, and the service life of the molded case circuit breaker is prolonged. The clamping block is arranged in the clamping groove, at the moment, the pulling plate is loosened, the first sliding plate can be reset through the elasticity of the first spring and the second spring, the fixing column can be reset, the molded case circuit breaker body is installed on the supporting plate, and the device is easy and convenient to install and disassemble.

Description

technical field [0001] The invention relates to the technical field of molded case circuit breakers, in particular to a molded case circuit breaker with a quick installation structure. Background technique [0002] The molded case circuit breaker can automatically cut off the current after the current exceeds the trip setting. Molded case refers to the use of plastic insulators as the casing of the device to isolate conductors and grounded metal parts. Molded case circuit breakers typically contain thermal magnetic trip units, while larger models have solid state trip sensors. Its trip unit is divided into: thermal magnetic trip and electronic trip, such as patent application number, CN201510601423.3 A molded case circuit breaker provided with a mechanical interlock device, including: the first molded case circuit breaker and The second molded case circuit breaker is equipped with a handle for controlling the closing and opening of the circuit breaker. The mechanical inter...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01H71/02H01H71/10H01H9/52

CPCH01H71/02H01H71/10H01H9/52

Inventor 袁传学

Owner 重庆砼山德机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com