Surface-modified pigment and application thereof

A surface modification, pigment technology, applied in the application of inkjet ink composition, modified color pigment field, to achieve excellent stability, good optical density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

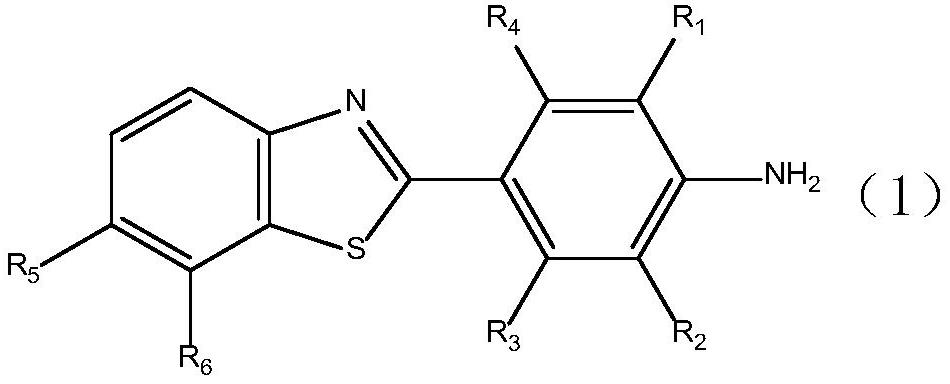

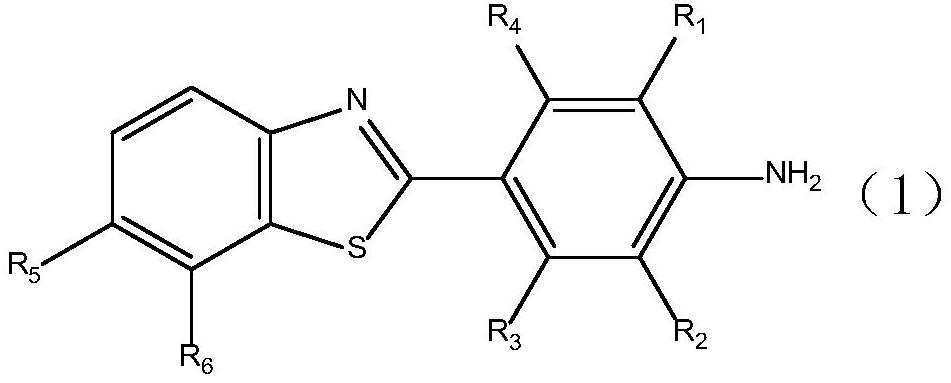

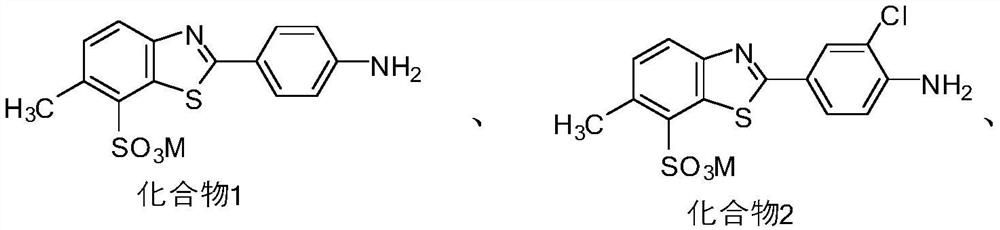

[0038]实施例1用2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸处理颜料蓝15:4

[0039]1)2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸(化合物1)重氮化

[0040]

[0041]将58g的2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸、150ml的水和40ml的15%NaOH溶液依次加入500ml三口瓶中,搅拌溶解,然后加入22ml30%的盐酸,冰水浴降温至0~5℃,缓慢滴入90ml的140g / L亚硝酸钠溶液,保温5℃反应1h,期间用淀粉-KI试纸检测,使反应液保持亚硝酸微过量,制得化合物1重氮盐,备用。

[0042]2)制备表面改性的有机颜料

[0043]将70g的颜料蓝15:4、700ml的水加入到2L的三口瓶中,开动搅拌,加热升温至50℃,预分散2h,缓慢加入上述1)制备的重氮盐溶液,通过使用H-酸斑点检测反应混合物样品中重氮盐的存在,将反应液和H酸滴在滤纸上,交叉处不显红色,则反应至终点,然后将反应物用15%的氢氧化钠调至中性。用反应物5倍体积的蒸馏水渗滤直至色浆的电导率低于1500μm / cm,以此获得纯化色浆分散体,并将色浆分散体的含固量浓缩至10%,然后砂磨10h,获得表面改性酞菁蓝的稳定水性色浆分散体,此外作为比较,按照实例1的相同操作步骤,用对氨基苯磺酸替代2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸(化合物1),对颜料蓝15:4进行表面改性。结果如下:

[0044]

[0045]结果显示,用化合物1重氮盐改性颜料蓝15:4的色浆在平均粒径、粘度及表面张力等方面于用对氨基苯磺酸改性颜料蓝15:4的色浆相当。

Example Embodiment

[0046]实施例2用2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸重氮盐处理颜料黄74

[0047]将47g的颜料黄74、600ml的水加入到2L的三口瓶中,开动搅拌,加热升温至56℃,预分散3h,缓慢加入实施例步骤1)制备的重氮盐溶液,通过使用H-酸斑点检测反应混合物样品中无重氮盐的存在后,后将反应物用15%的氢氧化钠调至中性。用反应物5倍体积的蒸馏水渗滤直至色浆的电导率低于1500μm / cm,以此获得纯化色浆分散体,并将色浆分散体的含固量浓缩至10%。然后砂磨10h,获得表面改性的颜料黄74的稳定水性色浆分散体。

Example Embodiment

[0048]实施例3用2-(4-氨基苯基)-6-甲基苯并噻唑7-磺酸重氮盐颜料红122进行表面处理。

[0049]将41g的颜料红122、800ml的水加入到2L的三口瓶中,开动搅拌,加热升温至45℃,预分散4h,缓慢加入实施例步骤1)制备的重氮盐溶液,通过使用H-酸斑点检测反应混合物样品中无重氮盐的存在后,将反应物用15%的氢氧化钠调至中性。用反应物5倍体积的蒸馏水渗滤直至色浆的电导率低于1500μm / cm,以此获得纯化色浆分散体,并将色浆分散体的含固量浓缩至10%。然后砂磨18h,获得表面改性的颜料红122的稳定水性色浆分散体。测得结果见下表:

[0050]

[0051]结果显示,用化合物1重氮盐处理颜料黄74和颜料红122的表面,能有效的对其颜料进行改性,从而获得具有小平均粒径、低粘度和高表面张力的改性颜料分散体。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com