Multi-layer commingling production capacity prediction method based on shaft multi-permeability coupling

A productivity prediction and multi-layer commingled production technology, applied in the field of oil and gas exploration, can solve the problems of reservoir permeability considerations and low accuracy of productivity prediction models, and achieve the effect of productivity prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

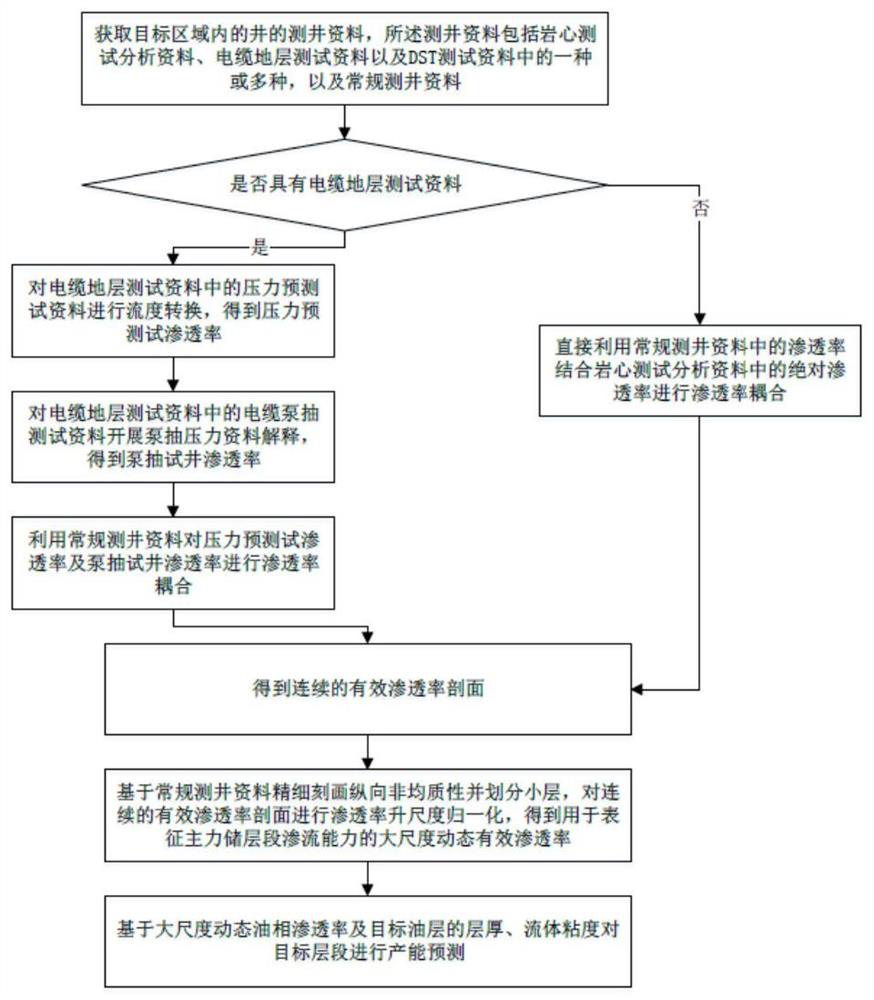

[0066] like Figure 1 to Figure 3 Shown is a first embodiment of a multi-layer commingled production productivity prediction method based on wellbore multi-permeability coupling, comprising the following steps:

[0067] S1: acquiring logging data of wells in the target area, the logging data includes one or more of core test analysis data, wireline formation test data, and DST test data, as well as conventional logging data;

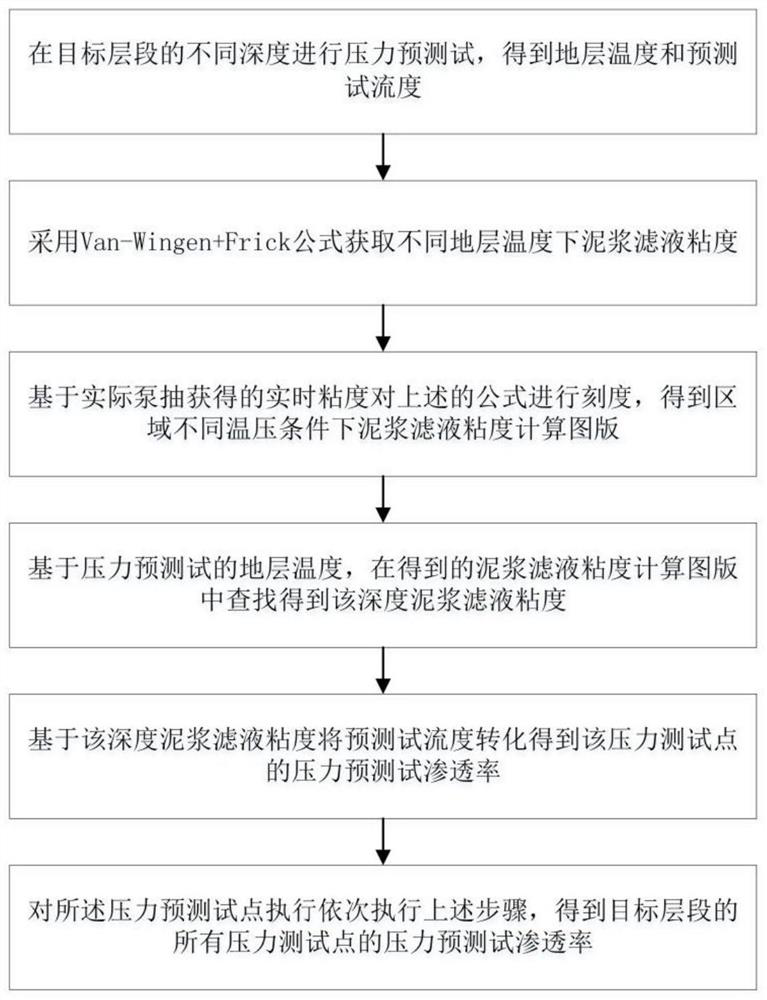

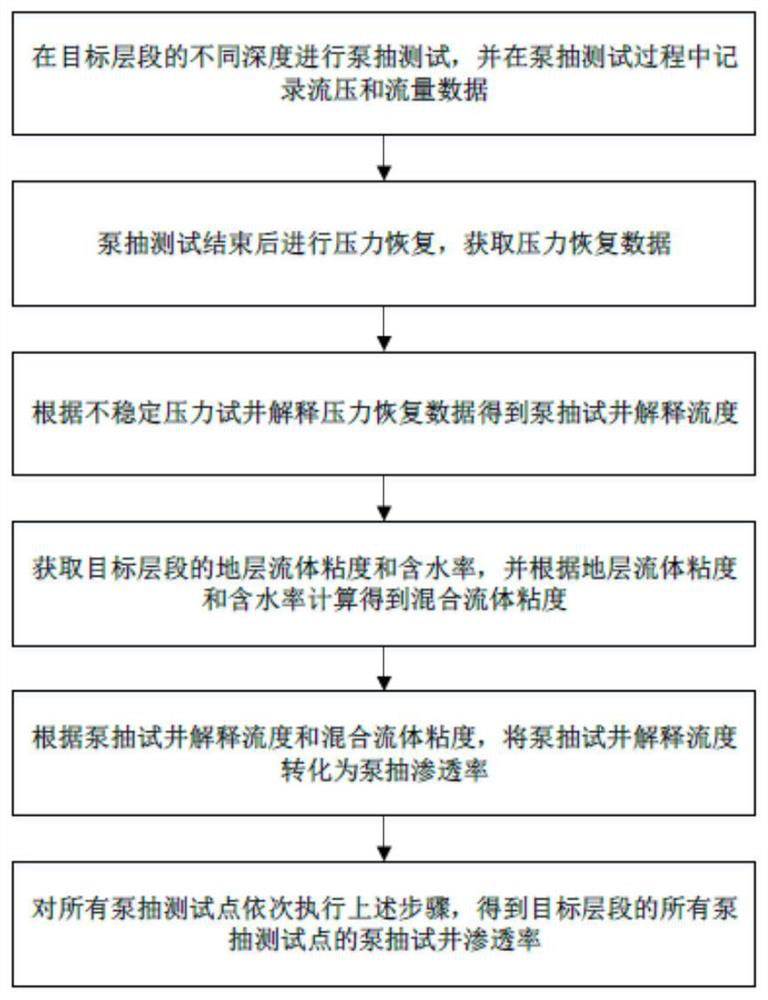

[0068] S2: Determine whether the target logging has cable formation test data, and if so, perform mobility transformation on the pressure pre-test data in the cable formation test data to obtain the pressure pre-test permeability, and perform the cable pumping test in the cable formation test data. Carry out the pumping pressure data interpretation to obtain the permeability of the pumping test well, and use the conventional logging data to couple the permeability of the pressure pre-test permeability and the permeability of the pumping test well to obta...

Embodiment 2

[0112] The only difference between this embodiment and Embodiment 1 is that when there is only conventional logging data, in step S2 in this embodiment, the permeability in the conventional logging data combined with the absolute permeability in the core test analysis data is used to conduct permeation. rate coupling, the continuous effective permeability profile is obtained as follows:

[0113] Select the absolute permeability of nuclear magnetic logging or flow unit subdivision or porosity-permeability correlation method, refer to the DST well test to explain the permeability and the relative permeability law of the core test area, and establish the relationship between the logging permeability and the oil phase relative permeability according to the flow unit. Fit the relational model and correct the permeability explained by the flow unit to obtain a continuous continuous effective permeability profile.

Embodiment 3

[0115] The only difference between this embodiment and Embodiment 1 or Embodiment 2 is that in this embodiment, the well logging is qualitatively analyzed according to the logging curve. When it is weak, in this embodiment, based on conventional logging data, the vertical heterogeneity is finely described and sub-layers are divided, and the permeability upscaling normalization for the continuous effective permeability profile specifically includes the following steps:

[0116] S321: Log the target well, find out all target oil layers, record the layer thickness of each target oil layer, and use conventional logging ELAN interpretation for each target oil layer to obtain the initial value of static permeability for reference;

[0117] S322: Based on the thickness-weighted arithmetic mean method, the thickness, piezometric fluidity and absolute permeability are scaled up to obtain the large-scale dynamic oil phase effective permeability.

[0118] In this embodiment, the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com