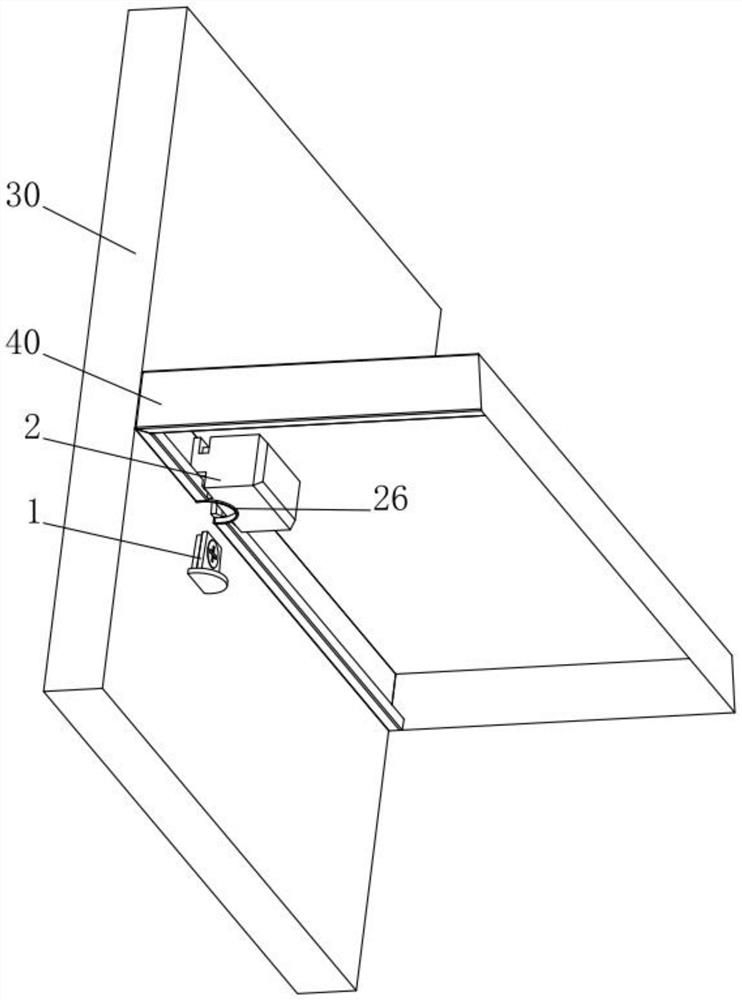

Hidden laminate support structure of metal cabinet

A metal cabinet, hidden technology, applied in applications, home appliances, furniture parts, etc., can solve the problem of how to install it firmly on the sheet metal laminate, etc., to achieve the effect of comfortable visual experience, reasonable force, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

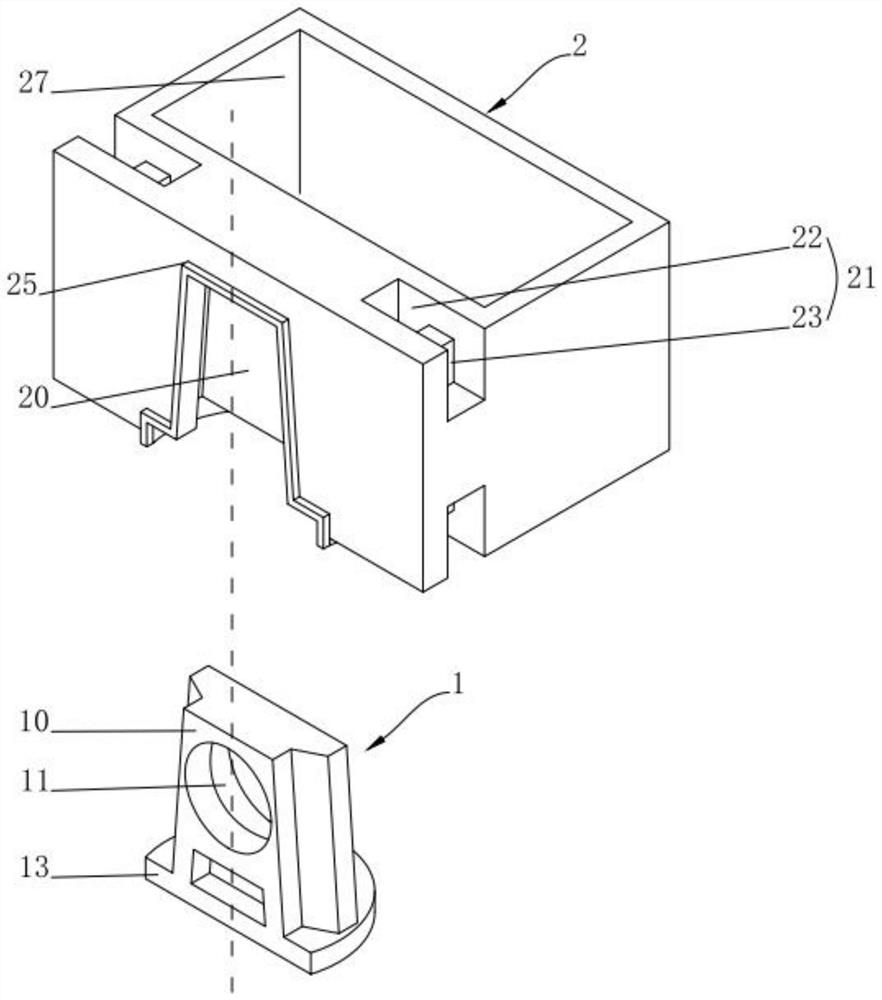

Examples

Embodiment 2

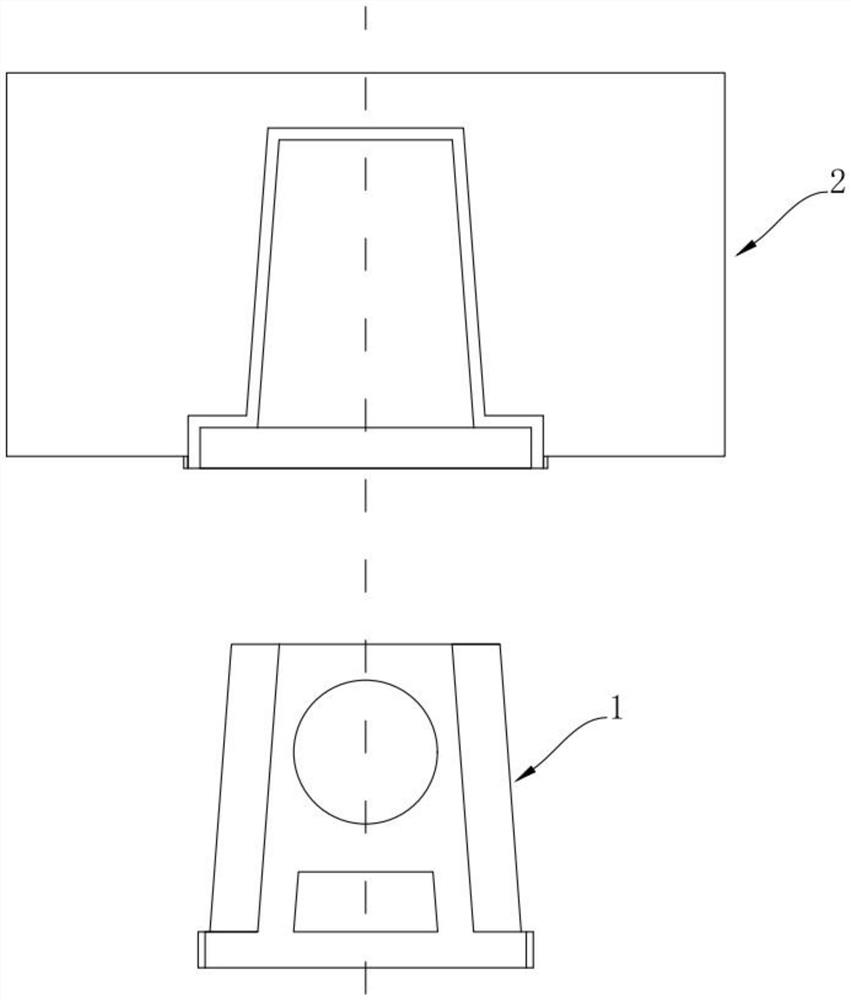

[0048] see Image 6 , the difference between this embodiment and embodiment 1 is that: a metal cabinet hidden laminate support structure of this embodiment 2 includes a support piece 1 and a mounting seat 2, and the shape of the support base 13 of the support piece 1 is square , the inner contour shape of the second flush frame 26 of the mounting seat 2 is square.

Embodiment 3

[0050] see Figure 7 , the difference between this embodiment and embodiment 1 and embodiment 2 is that: a metal cabinet hidden layer board support structure of this embodiment 3 includes a support piece 1 and a mounting seat 2, and a support base 13 of the support piece 1 The shape is square, and the bottom of the mounting seat 2 is not provided with a second flush frame 26 . The support base 13 of the holder 1 is directly attached to the bottom of the mounting base 2 , and the bottom of the support base 13 of the holder 1 is flush with the bottom of the sheet metal layer 40 .

Embodiment 4

[0052] see Figure 8 , the difference between this embodiment and embodiment 1, embodiment 2 and embodiment 3 is that: a metal cabinet hidden layer board support structure of this embodiment 4 includes a support member 1 and a mounting seat 2, and the support member 1 The support base 13 is not installed at the bottom, and the second flush frame 26 is not installed at the bottom of the mounting base 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com