Longitudinal swinging method for air grid

A technology of opposing swinging and wind grids, applied in glass tempering, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of serious wind spots, uneven wind exposure, uneven arrangement of air holes, etc., to improve the quality of tempering, The effect of uniform force and reduction of wind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

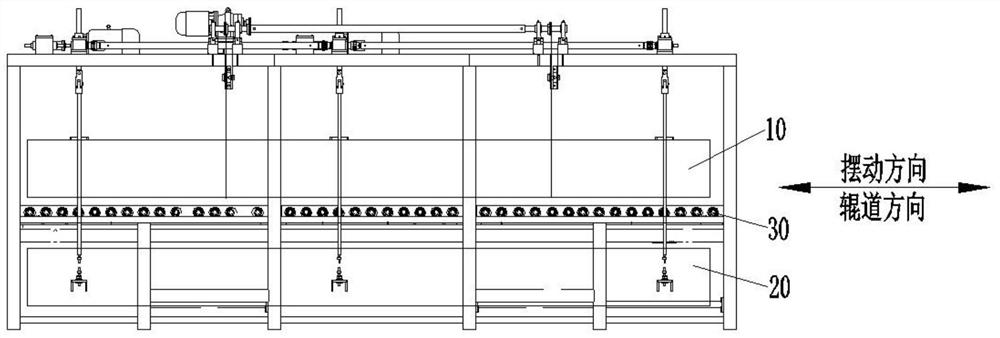

Embodiment 1

[0025] In this embodiment, the upper air grill 10 and the lower air grill 20 swing at a constant speed, and the swing rate is V=2mm / s or 15mm / s. In the description, the swing speed refers to the movement of the air grill between the two maximum swings. The speed does not include the speed change when the wind grill swings and turns, because when turning, there must be a process of speed reduction or increase. In this embodiment, the air grid first accelerates during a single swing, then at a constant speed, and finally decelerates. The process of acceleration and deceleration must exist, so the swing rate V=2mm / s or 15mm / s in this embodiment is Velocity in a uniform process. The swing range of the upper wind grille 10 and the lower wind grille 20 is fixed, and the swing range is D=10mm or 50mm. The speed U at which the conveying roller table 30 drives the glass to move is 40mm / s or 300mm / s. By controlling the swing rate and swing amplitude of the upper air grid 10 and the lo...

Embodiment 2

[0031] Embodiment five

Embodiment 3

In this embodiment, when the thickness of the glass is H=12mm, the upper air grid 10 and the lower air grid 20 swing at a constant speed, V=12mm / s, the frequency F of the upper air grid 10 and the lower air grid 20 is 1.5 circles / s, and the glass enters the upper air grid 10 and the blowing area of the lower wind grill 20, the time T=170s or 210s for the swing of the upper wind grill 10 and the lower wind grill 20. The speed U at which the conveying roller table drives the glass movement is 170mm / s. In this embodiment, the thickness H of the glass is selected to be 12mm. According to the thickness of the glass, by controlling the swing frequency and swing time of the upper air grid 10 and the lower air grid 20, the time for the air outlet to stay on the glass surface can be controlled, and the conveying roller table can be controlled. The transmission rate, under this parameter, the glass can achieve a better cooling effect and reduce the occurrence of wind spots.

[0034] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com