False touch correction system and method suitable for production line

A production line and false touch technology, applied in the field of false touch correction systems, can solve problems such as failure to completely shield interference clutter, system chain adverse reactions, and interference with the normal operation of production lines, to ensure accuracy, high precision, Avoid false trigger effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

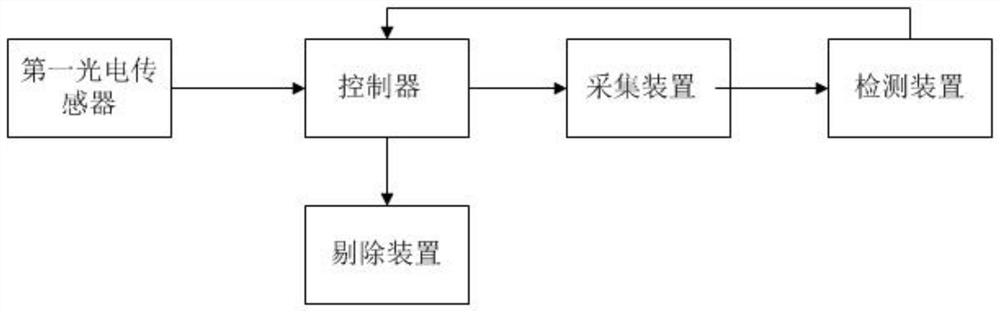

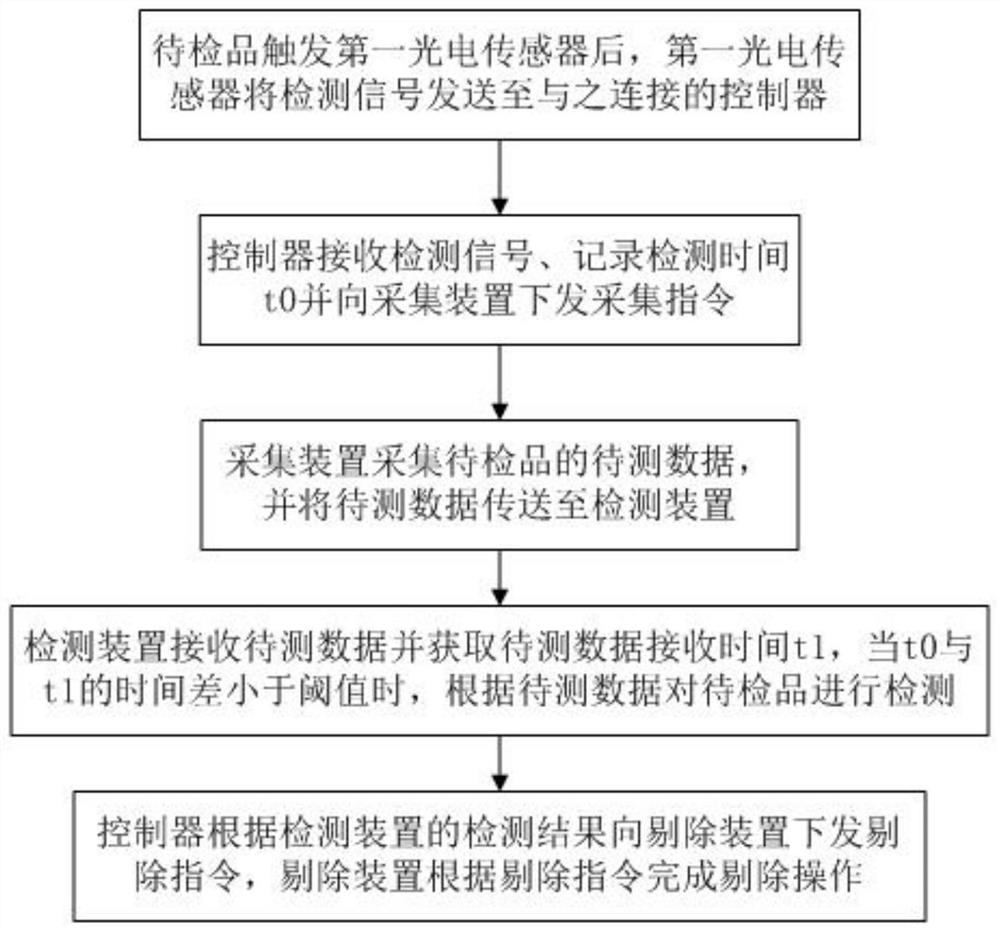

[0031] like figure 1 shown, false-touch correction systems for production lines, including:

[0032] The first photoelectric sensor: used to detect the arrival of the product to be inspected, and send the detection signal to the controller connected to it;

[0033] Controller: used to receive detection signals, record detection time t0, and issue acquisition instructions to acquisition devices, such as PLC;

[0034] Acquisition device: used to collect the data to be tested of the product to be tested, and transmit the data to be tested to the detection device;

[0035] Detection device: used to receive the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com