Fabricated building wall system and mounting method

A building wall and prefabricated technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of insufficient heat insulation effect and dependence on the structure of the wall panel itself, and achieve good heat insulation effect, Good fixation and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] By providing a prefabricated building wall system and an installation method, the embodiments of the present application solve the technical problem that the heat insulation of prefabricated walls in the prior art only relies on the structure of the wall panel itself, resulting in insufficient heat insulation effect.

[0036] In order to solve the above-mentioned technical problems, the general idea of the technical solutions provided by this application is as follows:

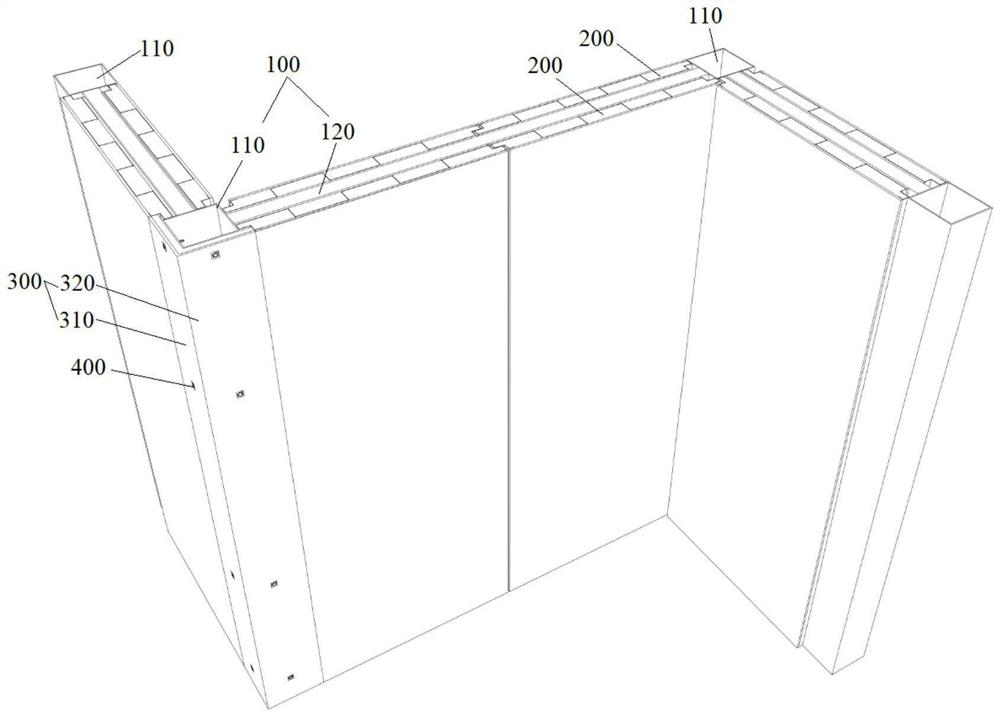

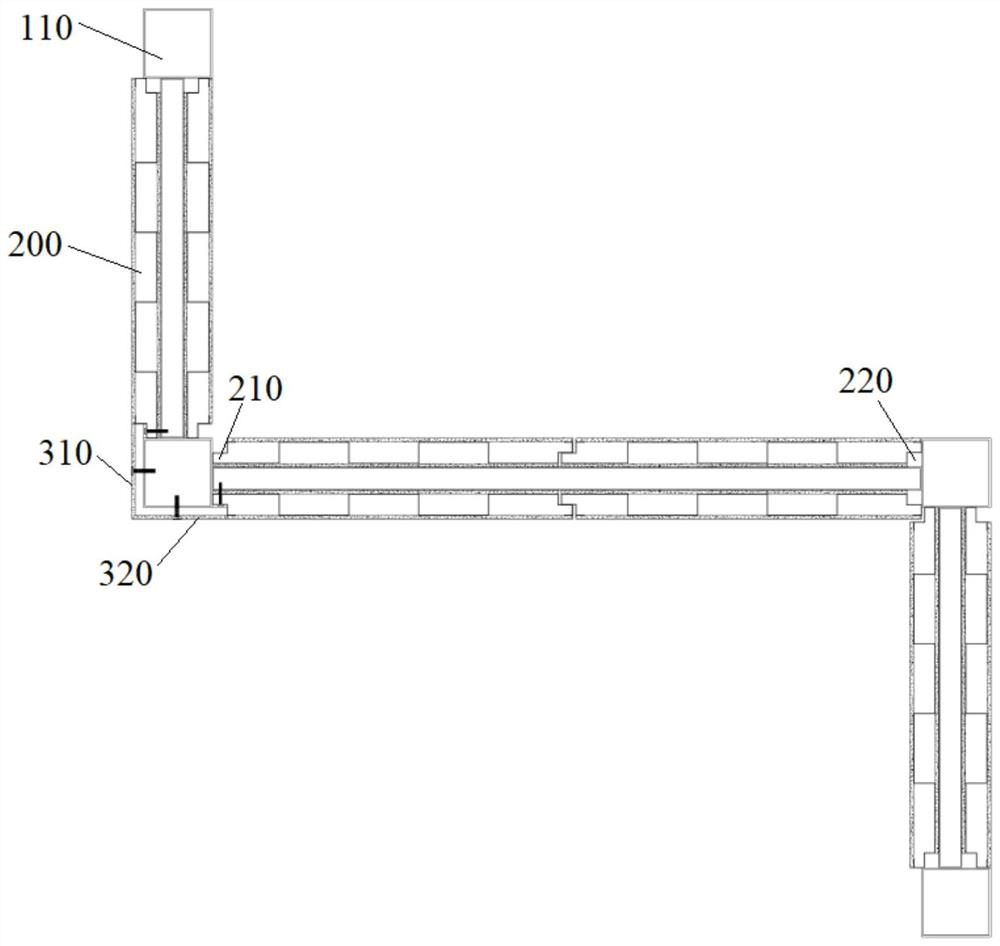

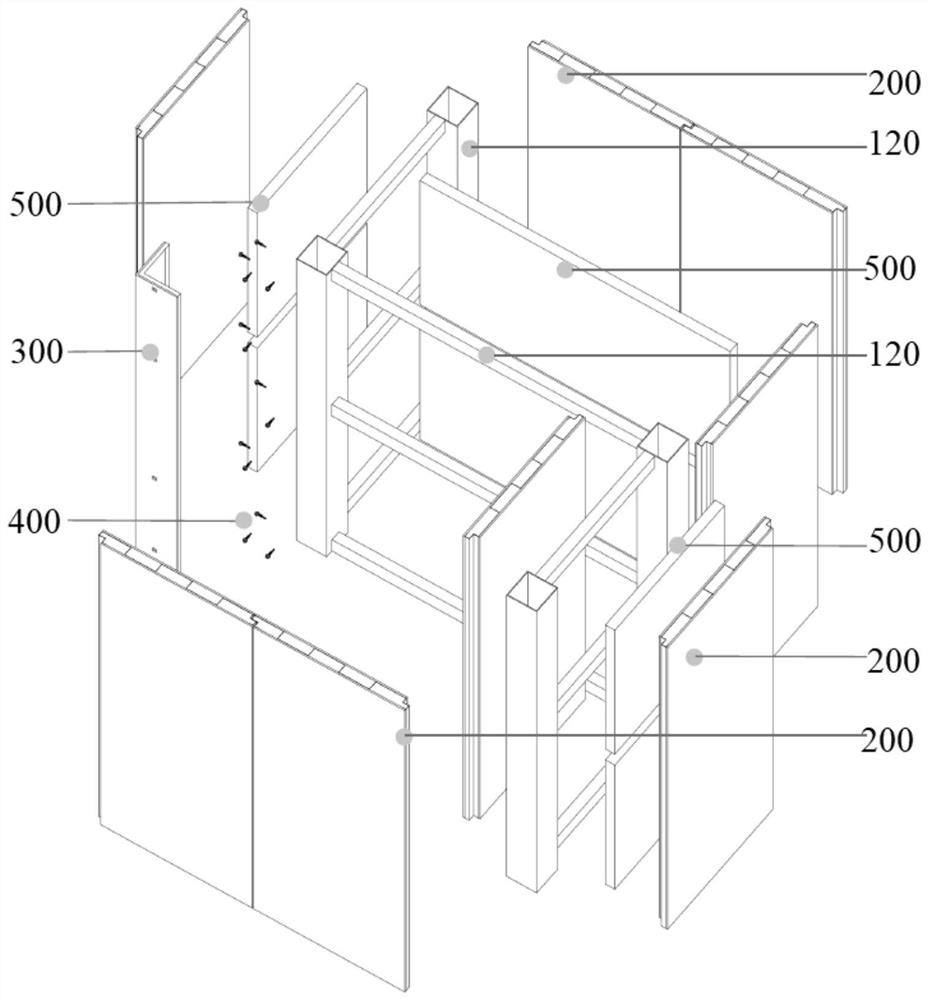

[0037] By setting the vertical column to bear the load, and by setting the horizontal connecting piece to connect the two adjacent columns, and making the front and rear sides of the column protrude from the front and rear sides of the connecting piece, the front and rear sides of the connecting piece can be placed on the connecting piece. The space for laying wall panels is left, and the wall panels are fixed on the connectors, which is simple and convenient to install; and an insulating cavity is for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap