Air passage structure of thin-wall workpiece die

A thin-walled workpiece and mold technology, applied in the field of airway structure, can solve the problems of thin-walled workpiece damage, small workpiece thickness, flashing, etc., and achieve the effects of reduced damage, low cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

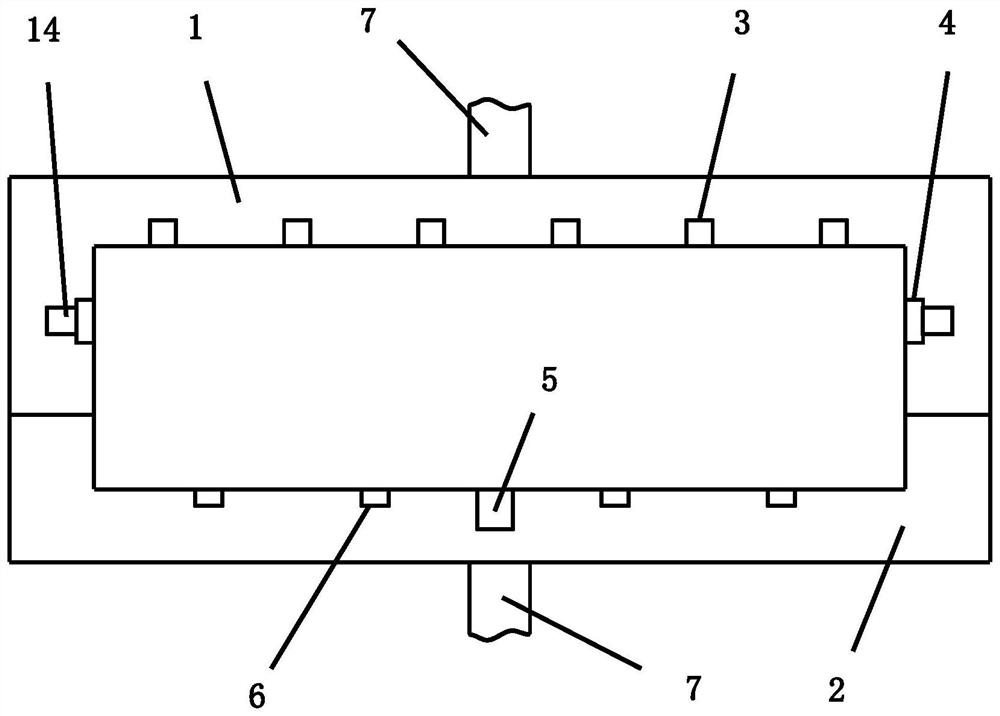

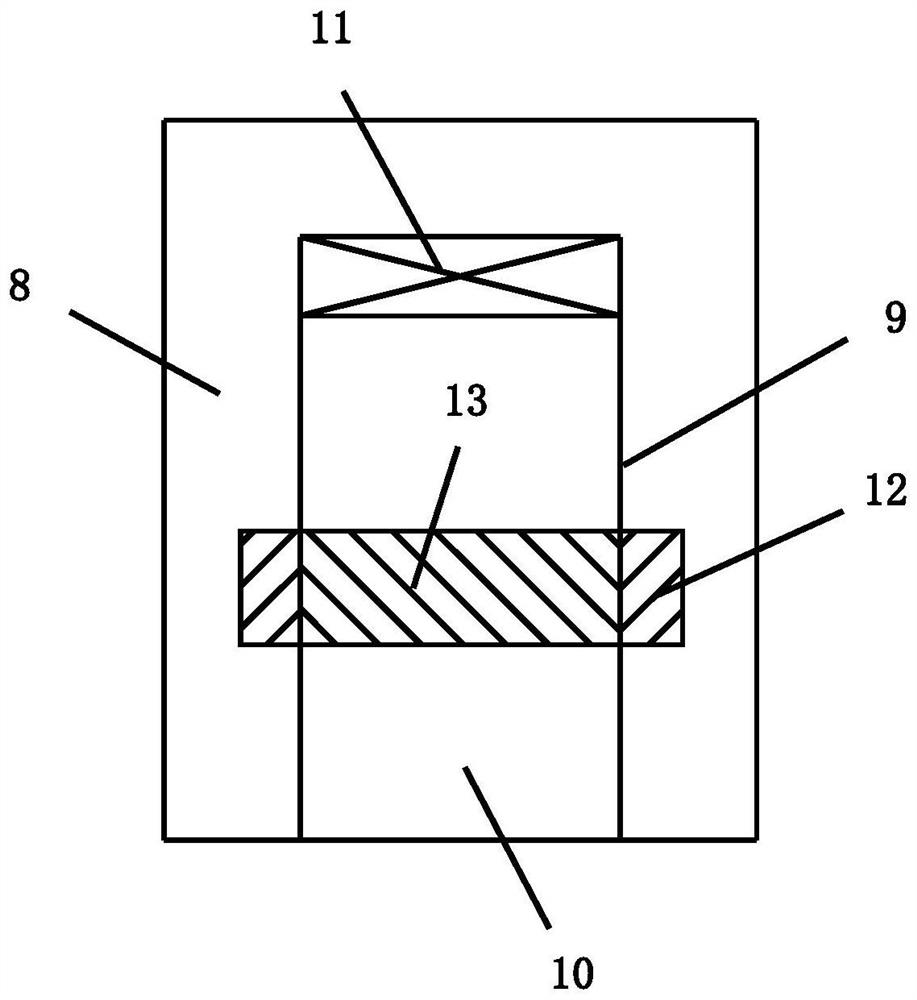

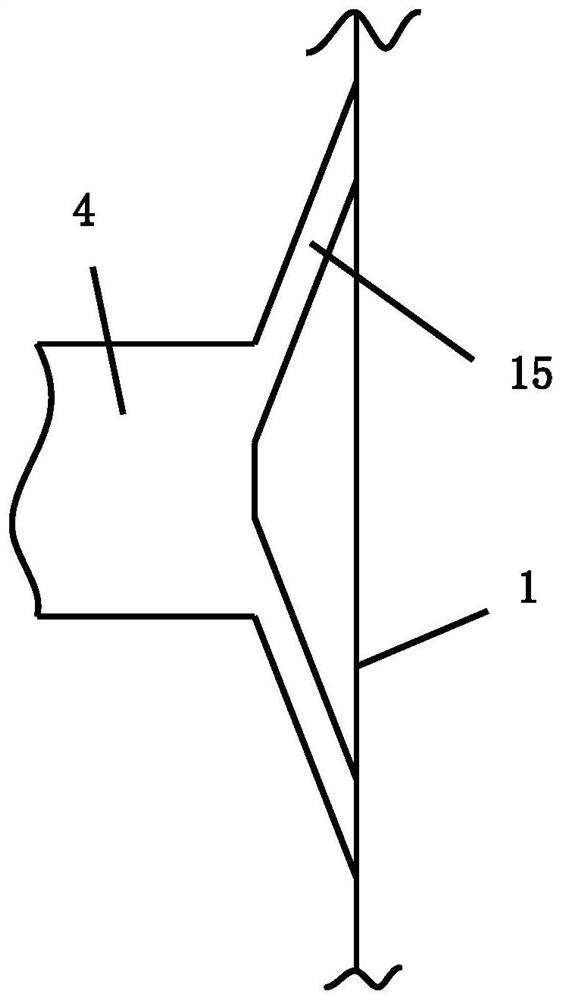

[0018] refer to Figure 1-5 , a specific embodiment of the present invention includes an upper mold 1 and a lower mold 2 that cooperate with each other, the top wall of the upper mold 1 in contact with the workpiece is evenly provided with a number of first air pins 3, and the side wall of the upper mold 1 in contact with the workpiece A number of air injection holes 4 are evenly arranged, a second air pin 5 is arranged in the center of the bottom of the lower mold 2 in contact with the workpiece, and a number of third air pins 6 are arranged annularly on the outside of the second air pin 5. The upper mold 1 Air inlet pipes 7 are respectively connected with the lower mold 2 , and the air inlet pipes 7 are respectively communicated with the first air pin 3 , the air injection hole 4 , the second air pin 5 and the third air pin 6 . The first air pin 3 includes a first housing 8, the first housing 8 is provided with a first mounting hole 9, the first pin 10 is movably inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com