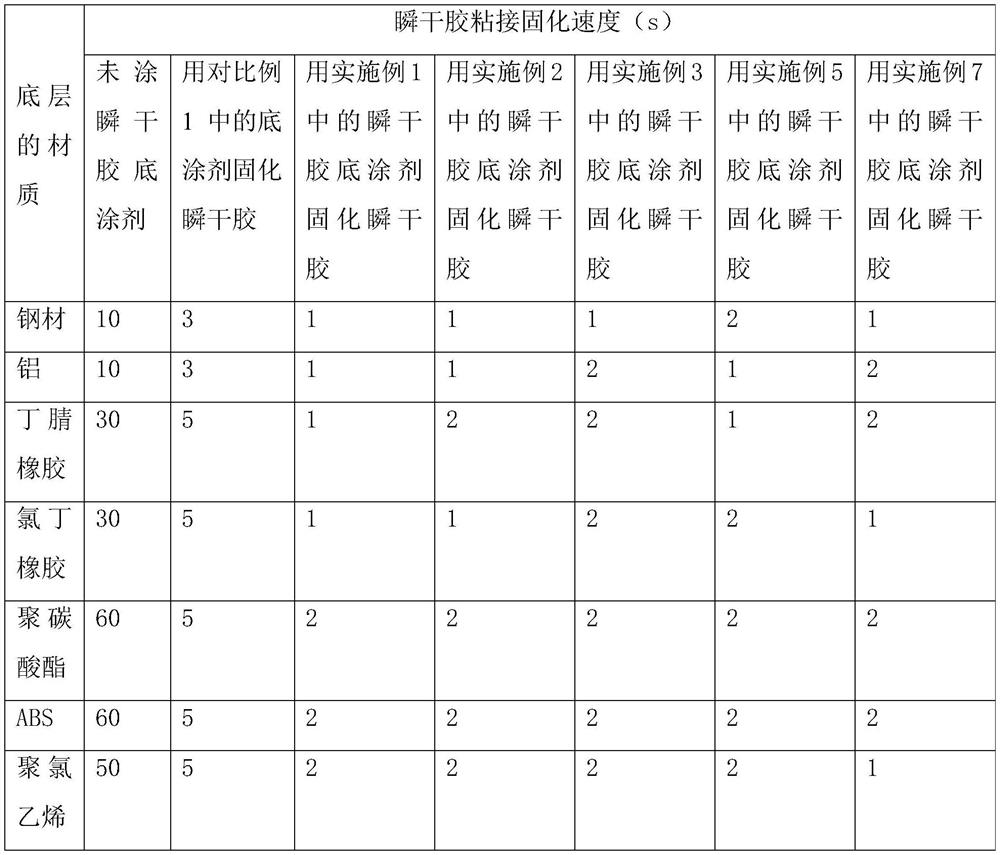

Instant adhesive primer and preparation method thereof

A primer and cyanoacrylate technology, applied in the field of cyanoacrylate, can solve the problems of whitening, blushing, affecting product appearance, transparency and mechanical properties of cyanoacrylate, achieving strong solubility, improving curing speed, reducing Moisture-absorbing whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of an instant adhesive primer, comprising: putting fluoride in a reaction kettle, evacuating the reaction kettle to a vacuum degree of -0.080MPa, then introducing argon gas, and adding in sequence under stirring conditions The methyl siloxane and the amine compound are heated to 50°C, continue to maintain the argon atmosphere, add the ionic liquid, stir for 30min until uniform, and drop to room temperature of 20-25°C to obtain the instant adhesive primer, wherein, according to the mass In parts, the ratio of fluoride, methylsiloxane, amine-based compound and ionic liquid was 90:3:2:5.

[0037] The fluoride was octafluoropentanol (Merrel Reagent Co., Ltd., Germany).

[0038] The methylsiloxane is tetramethyldisiloxane (Shanghai Aladdin Biochemical Technology Co., Ltd.).

[0039] The amine-based compound is a divinyltriamine-butyl glycidyl ether adduct. The method for preparing the amine compound is as follows: in a reaction kettle, in a nitrogen at...

Embodiment 2

[0042] A preparation method of an instant adhesive primer, comprising: putting fluoride in a reaction kettle, evacuating the reaction kettle to a vacuum degree of -0.090MPa, then introducing argon gas, and adding in sequence under stirring conditions The methyl siloxane and the amine compound are heated to 60°C, continue to maintain the argon atmosphere, add the ionic liquid, stir for 30min until uniform, and drop to room temperature of 20-25°C to obtain the instant adhesive primer, wherein, according to the mass In parts, the ratio of fluoride, methylsiloxane, amine-based compound and ionic liquid was 95:1:0.5:3.5.

[0043] The fluoride is perfluorohexane (Merrel Reagent Co., Ltd., Germany)

[0044] The methylsiloxane is hexamethyldisiloxane (Shanghai Aladdin Biochemical Technology Co., Ltd.).

[0045] The amine compound is trivinyltetraamine-butyl glycidyl ether adduct. The method for preparing the amine compound is as follows: in a reaction kettle, under a nitrogen atmosp...

Embodiment 3

[0048] A preparation method of an instant adhesive primer, comprising: putting fluoride in a reaction kettle, evacuating the reaction kettle to a vacuum degree of -0.085MPa, then introducing argon gas, and adding in sequence under stirring conditions Methyl siloxane and amine compound, heat up to 55°C, continue to maintain an argon atmosphere, add ionic liquid, stir for 30min until uniform, and cool to room temperature of 20-25°C to obtain an instant adhesive primer, wherein, according to mass In parts, the ratio of fluoride, methylsiloxane, amine compound and ionic liquid was 93:3:2:2.

[0049] The fluoride was decafluoropentane (Merrel Reagent Co., Ltd., Germany).

[0050] The methyl siloxane is γ-glycidyl ether oxypropyltrimethoxysilane (Shanghai Aladdin Biochemical Technology Co., Ltd.).

[0051] The amine compound is tetravinylpentamine-butyl glycidyl ether adduct. The method for preparing the amine compound is as follows: in a reaction kettle, under a nitrogen atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap