Automatic vending cabinet sharing system and method for automatically processing semi-finished food materials

An automatic vending and automatic processing technology, which is applied in the field of food cabinet system, can solve the problems of single types of products sold, high cost, and large volume, so as to save the time of taking meals and ensure the effect of hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

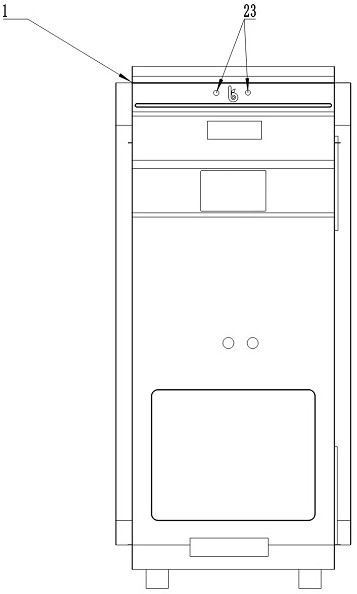

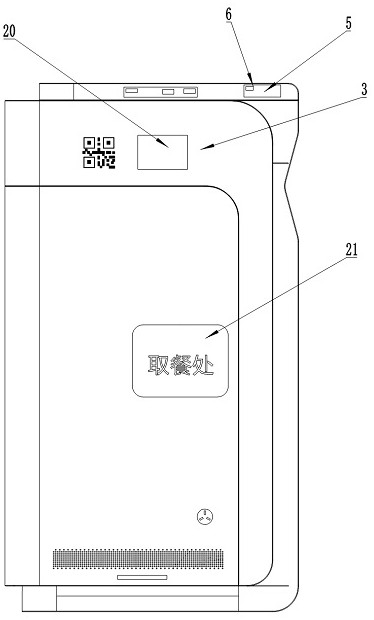

[0050] like Figure 1-Figure 6 As shown, in this embodiment, including automatic production of semi-finished food ingredients and meals automatic vending cabinet 1, on-site automatic production of semi-finished food ingredients and meals equipment and system 2, automatic vending cabinet equipment and system 3 and its will be mounted on or produced in the described On the cabinet bottom frame bracket, the bracket also includes an energy supply device, which can be directly powered or self-provided. According to the needs of the guests, after arriving at the fixed location of the automatic vending cabinet, unmanned on-site automatic production of semi-finished food ingredients, cooked, steamed. Cooked, fried, cooked and cooked to the edible le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com