Natural gas engine torque control method and system

An engine torque and control method technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of poor engine torque response, small engine torque output, and large delay of natural gas engine, so as to improve torque response, offset Delayed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The demand for AMTs for vehicles, especially commercial vehicles, is increasing year by year. At the same time, customers have put forward higher requirements for shifting comfort. Natural gas engines, as an important part of commercial vehicles, have greater challenges. At this stage, in solving the torque of natural gas engines When the response delay is large, when the engine performs normal PI control, the engine is in the early stage of the twisting stage, and the torque difference is relatively small, the actual torque output of the engine calculated by PI is small, and the natural gas engine itself has a relatively large delay, resulting in the engine Torque responsiveness is poor.

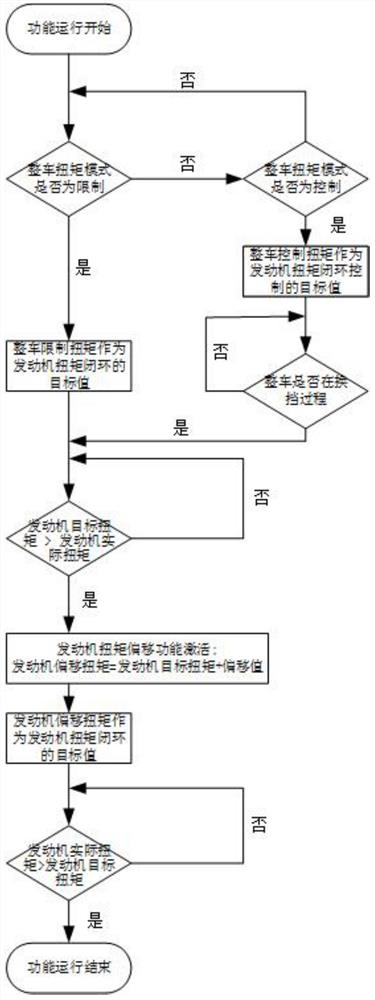

[0041] In view of the above problems, the present embodiment provides a torque control method for a natural gas engine, including:

[0042] Receive shift control commands;

[0043] Determine whether the control command is a torque limit command or a torque control command, and deter...

Embodiment 2

[0059] This embodiment provides a natural gas engine torque control system, including:

[0060] a data acquisition module, configured to: receive a shift control command;

[0061] The command judgment module is configured to: judge whether the control command is a torque limit command or a torque control command, and determine a closed-loop target value of the engine torque according to the judgment result, so as to obtain the engine target torque;

[0062] A twist-back stage determination module, configured to: determine that the engine is in a twist-back stage in the shifting process according to the comparison between the target engine torque and the actual torque of the engine;

[0063] The control module is configured to: control the engine torque by using the engine offset torque as the target value of the engine torque closed-loop control during the torque-back phase; wherein the engine offset torque is equal to the difference between the engine target torque and the ca...

Embodiment 3

[0066] This embodiment provides a computer-readable storage medium on which a computer program is stored, and when the program is executed by a processor, implements the steps of the natural gas engine torque control method described in Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap