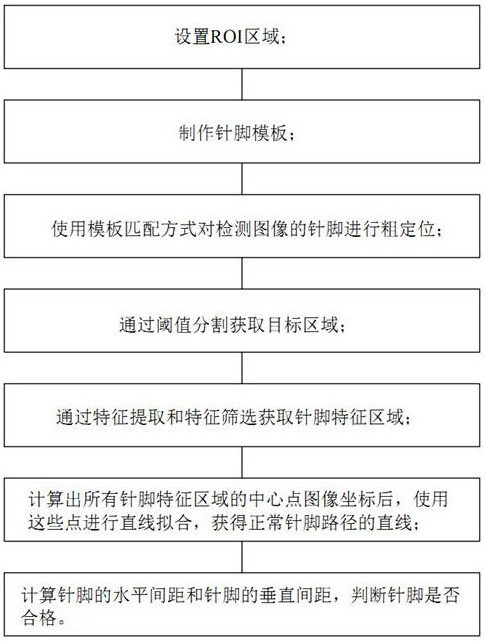

Visual inspection method for connector pins

A visual inspection and connector technology, applied in the field of visual inspection, can solve the problems of false detection, false detection, missed detection, difficult control of detection standards and quality, slow detection speed, etc. Accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0022] The present invention provides a visual detection method for connector pins, including a visual solution for detection and a detection algorithm, wherein when determining the visual solution for detection, it is necessary to determine a camera and lens for detection, and a light source for detection.

[0023] Specifically, in this solution, different models of cameras and lenses are selected according to the size and detection accuracy requirements of different products. The selection method is as follows:

[0024] The size of the product to be tested is: L*W*H (where L*W is the surface to be tested, and L is the long side);

[0025] The detection accuracy is: Acc;

[0026] The precision coefficient is: k (3≤k≤10);

[0027] The zoom ratio of the field of view is: r (r>1);

[0028] The pixel size is: p;

[0029] The working distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com