False twisting device for rotor spinning device

A technology of air spinning and false twisting, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines. The effect of easy disassembly and maintenance or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] see Figure 1 to Figure 6 , the present invention provides a kind of technical scheme:

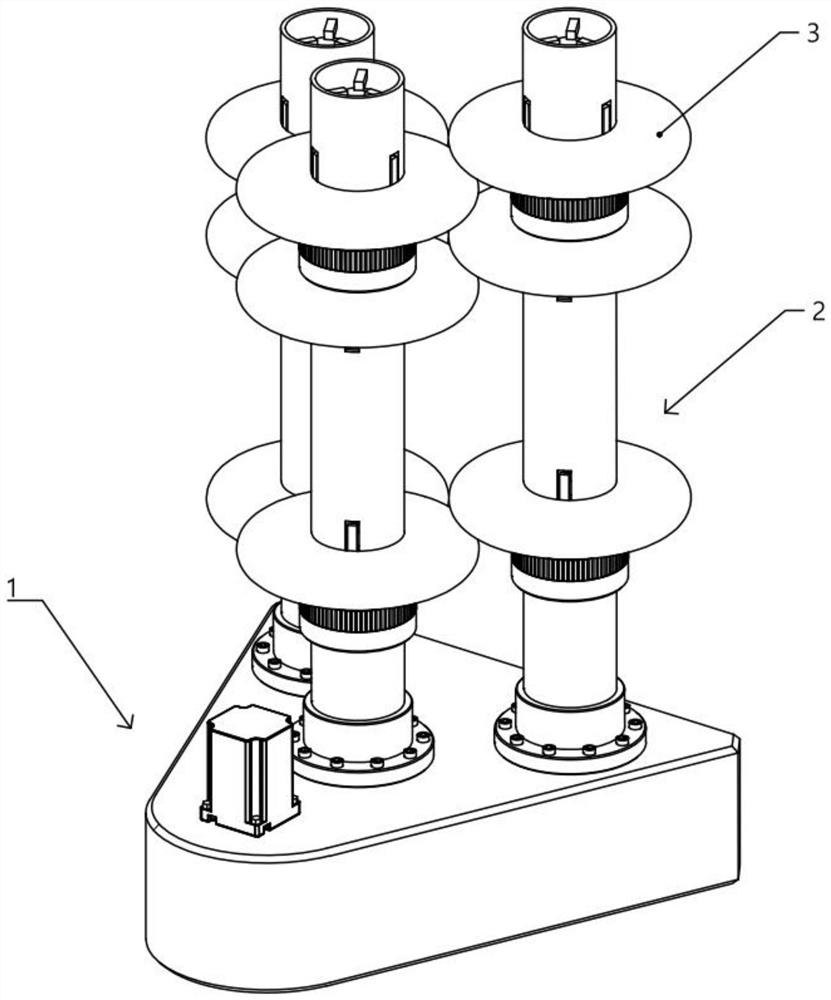

[0025] A false twisting device for an air-jet spinning device, comprising a drive assembly 1, a stepped shaft assembly 2, a false twisting disc 3 and a conical sleeve 4, wherein:

[0026] The three stepped shaft assemblies 2 are triangularly distributed on the driving assembly 1 and are drively connected with the driving assembly 1. The stepped shaft assembly 2 is provided with three false twist discs 3, wherein the driving assembly 1 is composed of a gearbox and a motor, and the driving assembly 1 is composed of a gearbox and a motor. The specific components and the connection relationship between the components are conventional settings in the field, and will not be repeated here, wherein the ultimate purpose of the drive assembly 1 is to drive the three stepped shaft assemblies 2 to rotate, and then realize false twisting work;

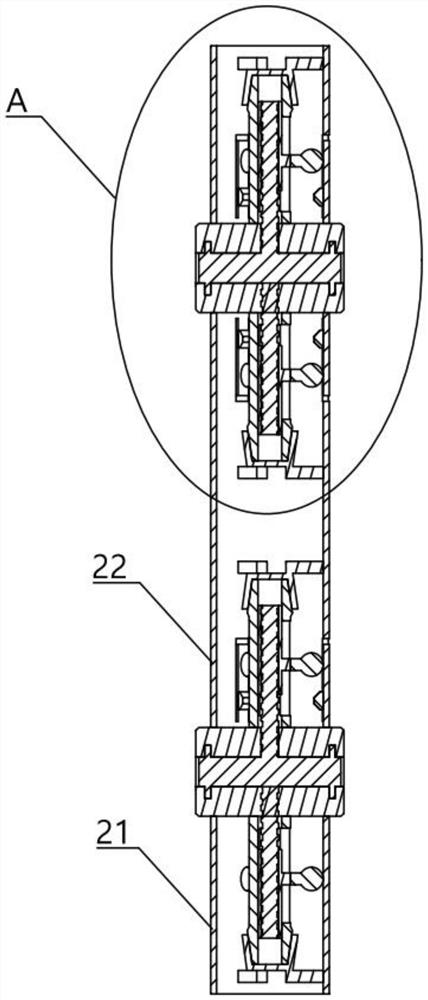

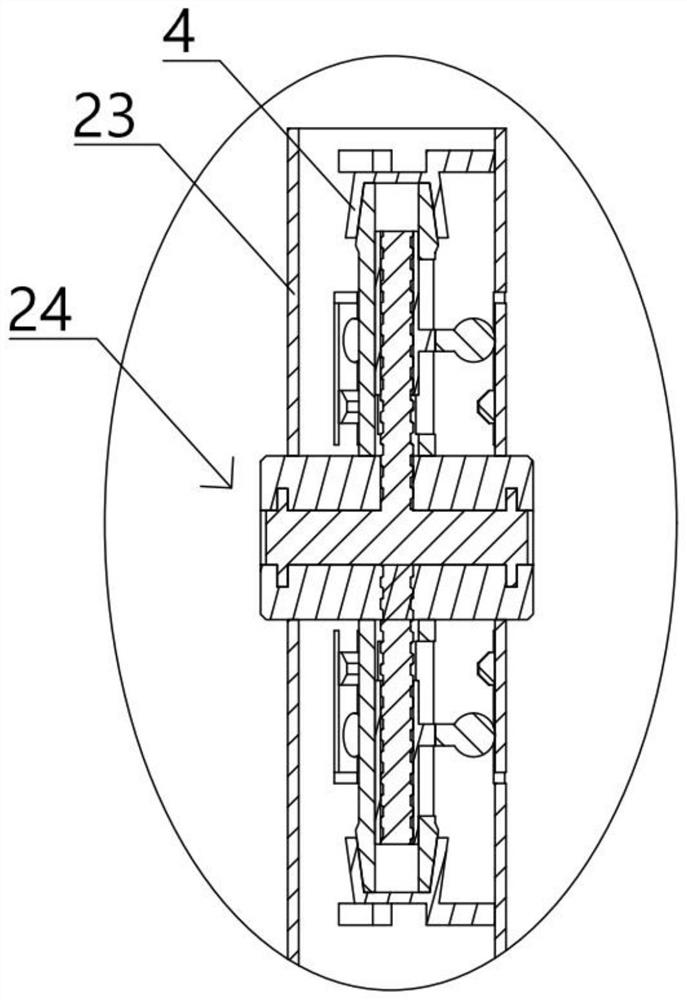

[0027] The stepped shaft assembly 2 includes a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com