Deep dehumidification system driven by cascade heat pump and application

A heat pump-driven, deep technology, used in heat recovery systems, lighting and heating equipment, energy-saving heating/cooling, etc., can solve problems such as inability to fully meet the requirements of deep dehumidification, limited dehumidification range, and large energy consumption for regeneration. Remarkable energy saving effect, improving environmental adaptability and reducing regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

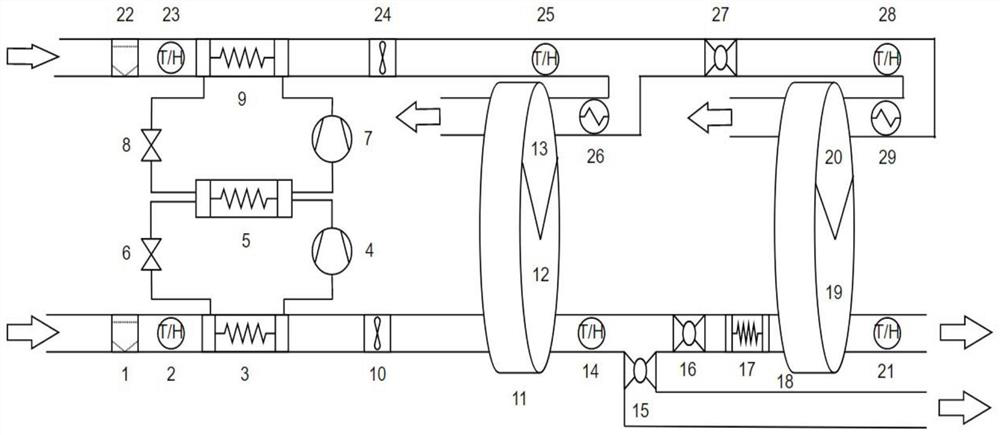

[0026] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0027] In view of the deficiencies of the prior art, the solution of the present application is to use the low-temperature stage evaporator (cold end) of the cascade heat pump and the double-stage dehumidification rotor to sequentially perform condensation dehumidification and rotor dehumidification on the humid air to achieve the deep dehumidification requirement, The high-temperature heat energy provided by the high-temperature stage condenser (hot end) of the cascade heat pump is used to heat the runner regeneration air, which effectively solves the problems of insufficient efficiency of the traditional dehumidification system and high regeneration energy consumption.

[0028] An embodiment of the present application provides a deep dehumidification system driven by a cascade heat pump, such as figure 1 As shown, it includes: a cascade heat pump wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com