Array substrate and display panel

An array substrate and metal array technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of large trace impedance and uneven display, and achieve the effect of reducing trace impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

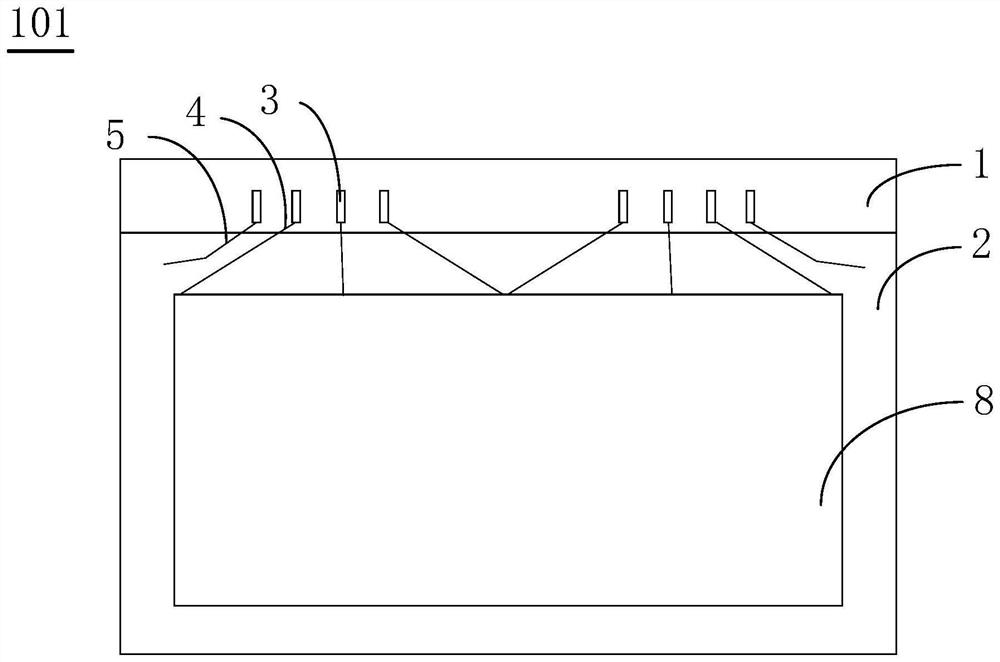

[0038] like figure 1 As shown, the first array substrate 101 provided in the first embodiment of the present application includes a binding area 1 , a non-display area 2 , and a display area 8 .

[0039] The non-display area 2 is located around the display area 8 . The binding pin 3 from the binding area 1 extends to the non-display area 2, respectively, the data signal in the binding pin 3 is connected to the fan-out trace 4, and the GOA signal and the com signal in the binding pin 3 are connected to the WOA Route 5.

[0040] In the present embodiment, the non-display area 2 is provided with a plurality of WOA lines 5 and a plurality of fan-out lines 4, and the plurality of WOA lines 5 and the plurality of fan-out lines 4 are arranged at intervals from each other. Specifically, the plurality of WOA lines The traces 5 are concentrated in one area, and the multiple fan-out traces 4 are concentrated in another area. There is a large gap between the two areas. The non-display a...

Embodiment 2

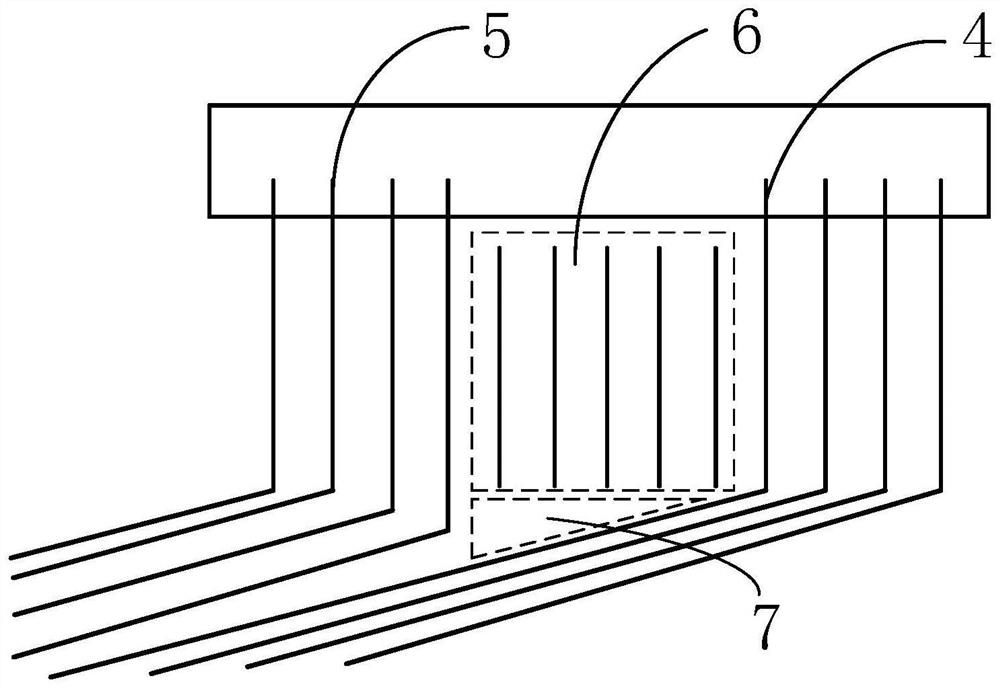

[0055] like Figure 4 As shown, the spacing between adjacent virtual traces 6 changes in steps from the side of the plurality of WOA traces 5 to the side of the plurality of fan-out traces 4 .

[0056] In this embodiment, the virtual traces 6 are divided into different gradients, the number of gradients is not limited, the spacing between the virtual traces 6 between different gradients is different, and the spacing between the virtual traces 6 of the same gradient is the same . From one side of the virtual trace 6 to the other side, the length of the spacing changes from large to small, specifically by comparing the spacing between the WOA traces 5 and the fan-out traces 4, when the distance between the WOA traces 5 is greater than the distance between the fan-out traces 4, then the trace spacing of the virtual trace 6 gradient close to the WOA trace 5 side is greater than the trace distance of the virtual trace 6 gradient close to the fan-out trace 4 side, when The distanc...

Embodiment 3

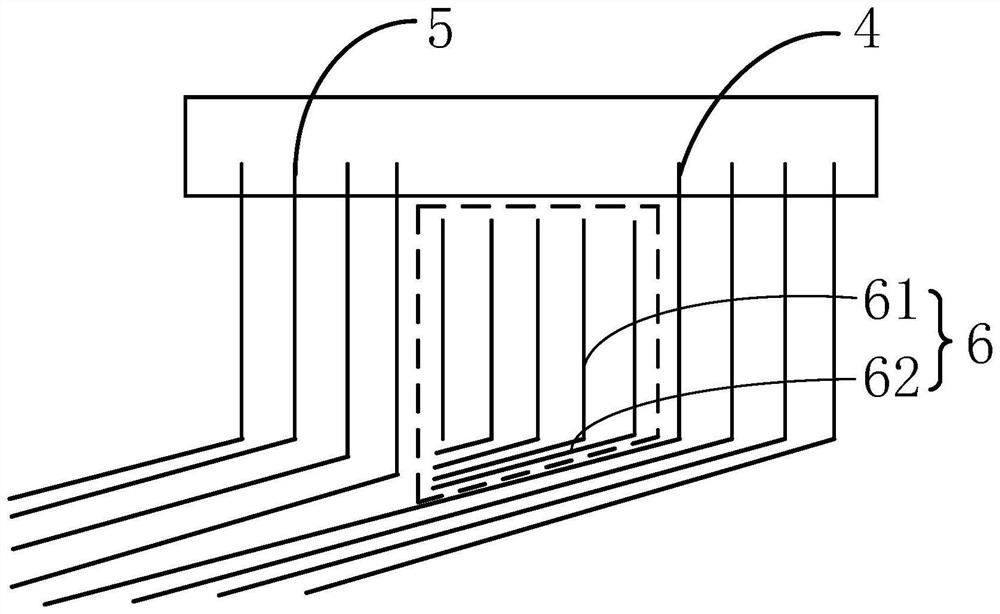

[0060] like Figure 5 As shown, the spacing between the multiple virtual traces 6 changes linearly from one side of the multiple WOA traces 5 to the side of the multiple fan-out traces 4 , that is, the variation of the spacing is extremely small and approximately a continuous change.

[0061] Obtain the spacing between WOA traces 5, and obtain the spacing between fan-out traces 4. The spacing between virtual traces 6 near the metal traces is similar to the spacing between WOA traces 5, and virtual traces 6 are close to the fan-out. The spacing on one side of the line 4 is similar to the distance between the fan-out traces 4 , and the spacing on one side of the virtual trace 6 changes gradually to the spacing between the virtual traces 6 on the other side.

[0062] In other embodiments, while keeping the distance between the dummy traces 6 the same as the distance between the dummy traces 6 in this embodiment, the trace length of the dummy traces 6 may be appropriately extended...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com