Gravel screening device based on machine-made sand production

A screening device and a technology for machine-made sand, which are applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of increased mesh blockage of the drum, inability to perform screening, and the influence of the normal screening of the drum, and achieve enhanced recycling. Elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

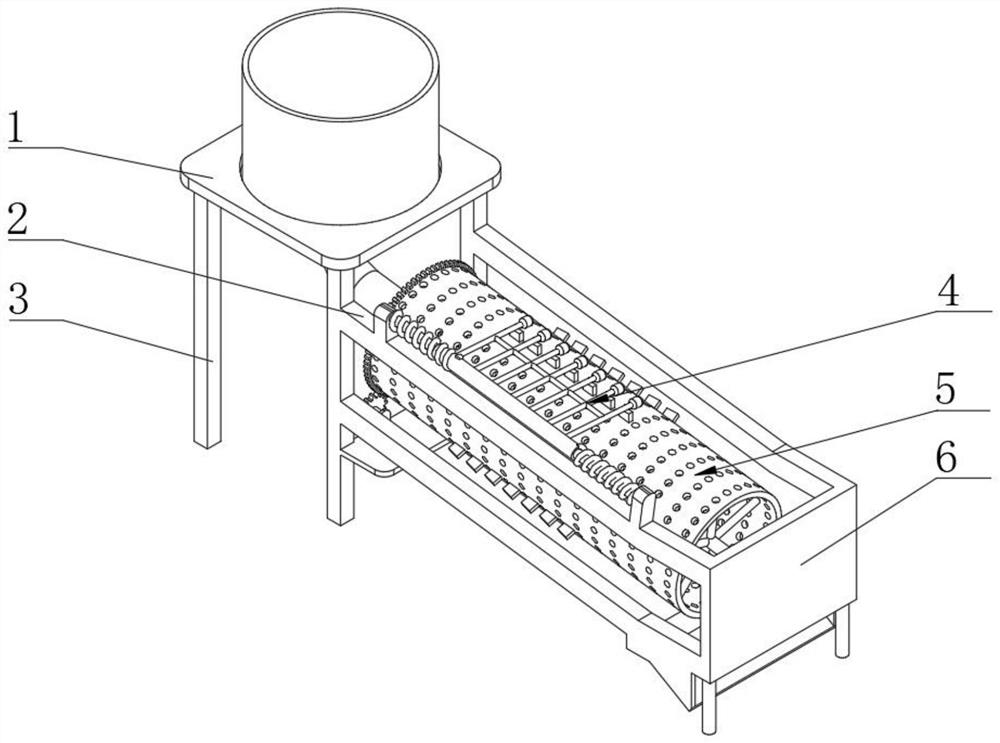

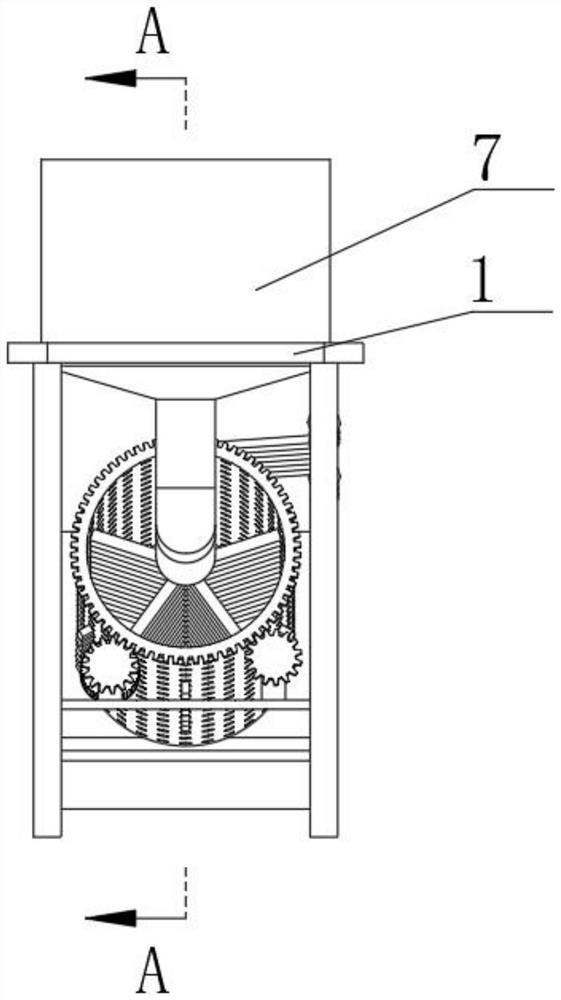

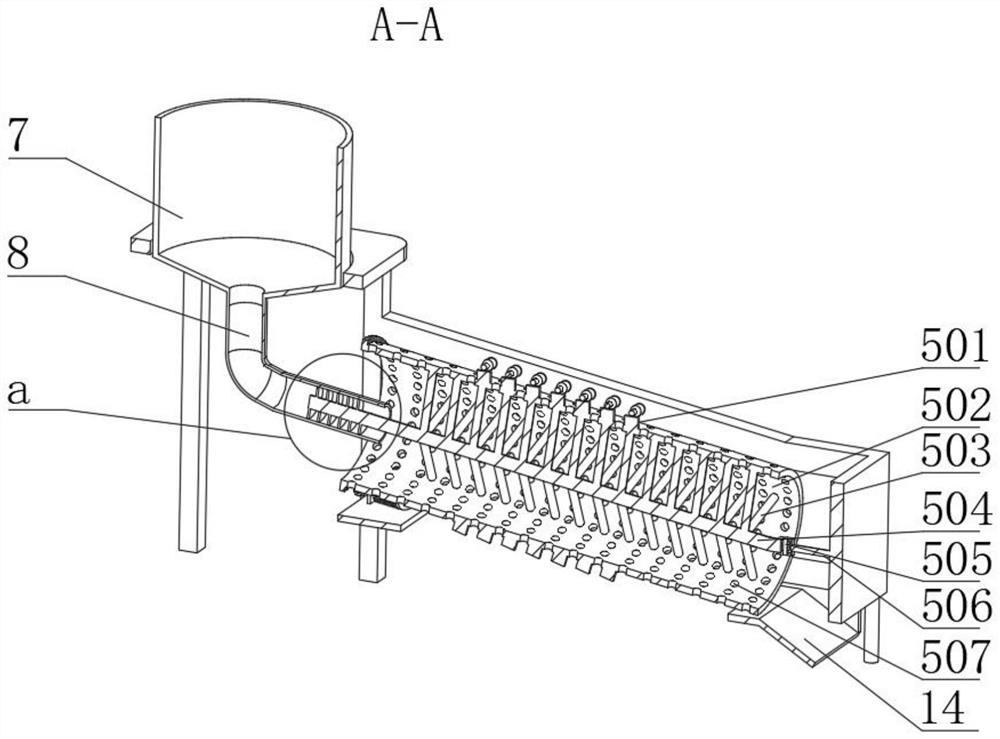

[0031] like Figures 1 to 6 As shown, the embodiment of the present invention provides a sand and gravel screening device based on machine-made sand production, comprising a fixed platform 1, and four platform support rods 3 are fixedly installed on the surface of the fixed platform 1, wherein two of the platforms support Both ends of the rod 3 are fixedly installed with an oblique fixed rod 2, and a movable screening mechanism 5 is movably installed between the four oblique fixed rods 2, and a knock-off mechanism is installed on one side of the movable screening mechanism 5. 4. A feeding cylinder 7 is fixedly installed inside the fixed platform 1, and one end of the feeding cylinder 7 is integrally provided with a material conduit 8, and one end of the material conduit 8 is installed inside one end of the movable screening mechanism 5, A discharge plate 14 is integrally provided on the lower surfaces of one end of the two oblique fixing rods 2 away from the platform support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com