Pulsation ultrasonic wet-type high-frequency vibration screening device for laboratory

A high-frequency vibrating screen, laboratory technology, applied in the fields of filter screen, solid separation, recycling technology, etc., can solve the problems of easy screen blocking, low screening efficiency, high labor intensity of test personnel, etc., to reduce screen blocking. The effect of reducing the difficulty of screening and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings.

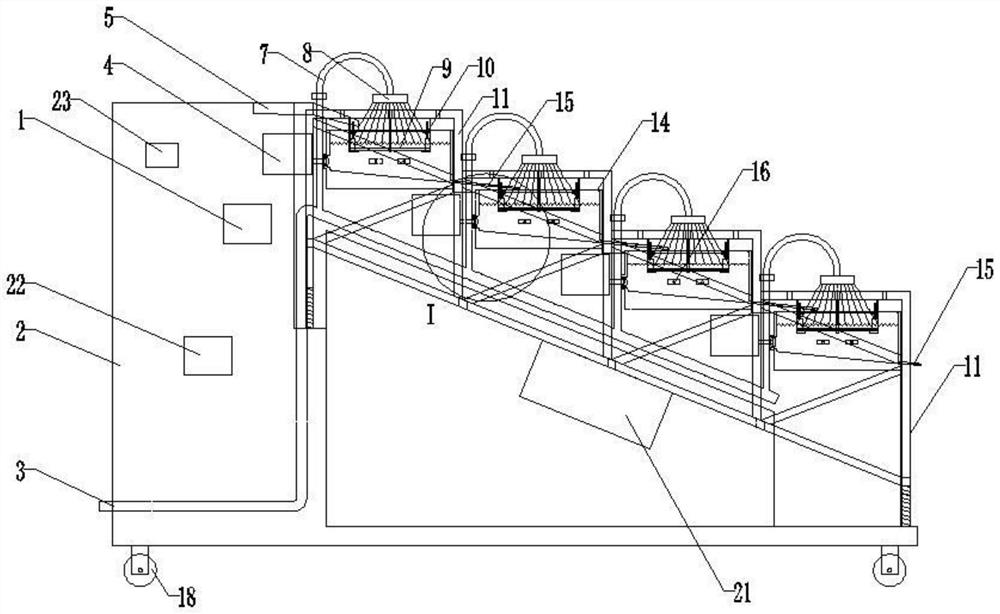

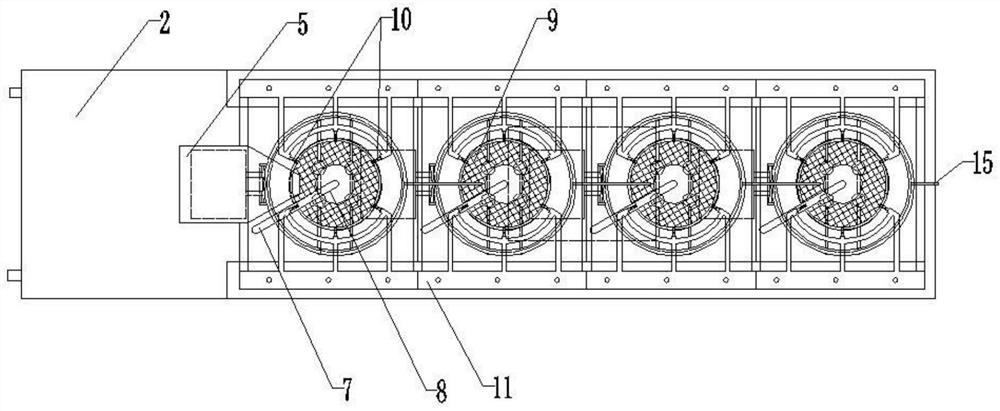

[0031] like Figure 1 to Figure 9 As shown, the laboratory-use pulsating ultrasonic wet-type high-frequency vibration screening device of the present invention comprises a base 2, a support 11 and several screening units, the support 11 is elastically arranged on the base 2, and the base 2 is provided with a variable frequency ultrasonic generator device 1;

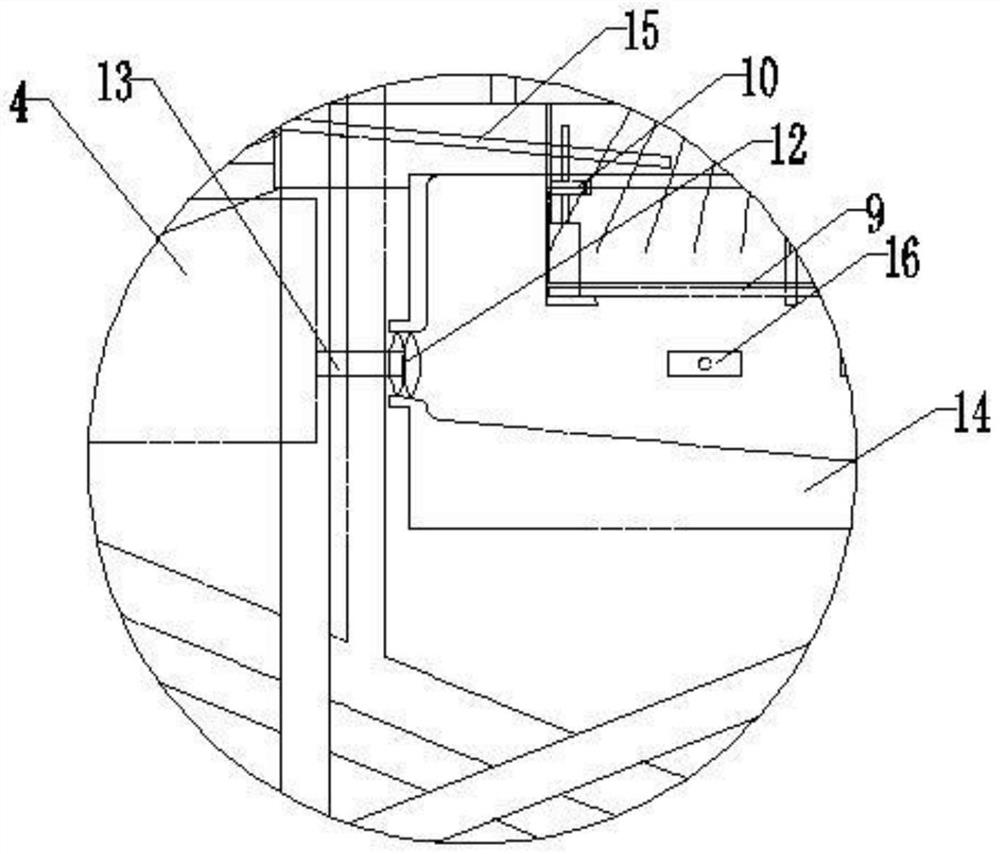

[0032] The screening unit includes a frequency conversion pulsation generator 4, a screening water tank 14, a water supply pipe 7, a screen fixture 10, a screen 9 and an ultrasonic transducer 17. The bottom surface of the screening water tank 14 is an inclined surface structure, and the inclined place is provided. There is a ore discharge pipe 15, the screen clamp 10 is connected with the bracket 11, the screen 9 is arranged in the middle of the screening water tank 14 through the screen clamp 10, and the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com