Omnibearing welding device for narrow and small space in barrel-like workpiece

A narrow space, welding device technology, applied in the direction of welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of difficult welding repair of internal operating equipment, difficult to ensure welding quality, etc., to achieve multi-angle welding and improve welding quality , The effect of reducing the difficulty of on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but these descriptions are only exemplary and are not intended to limit the protection scope of the present invention.

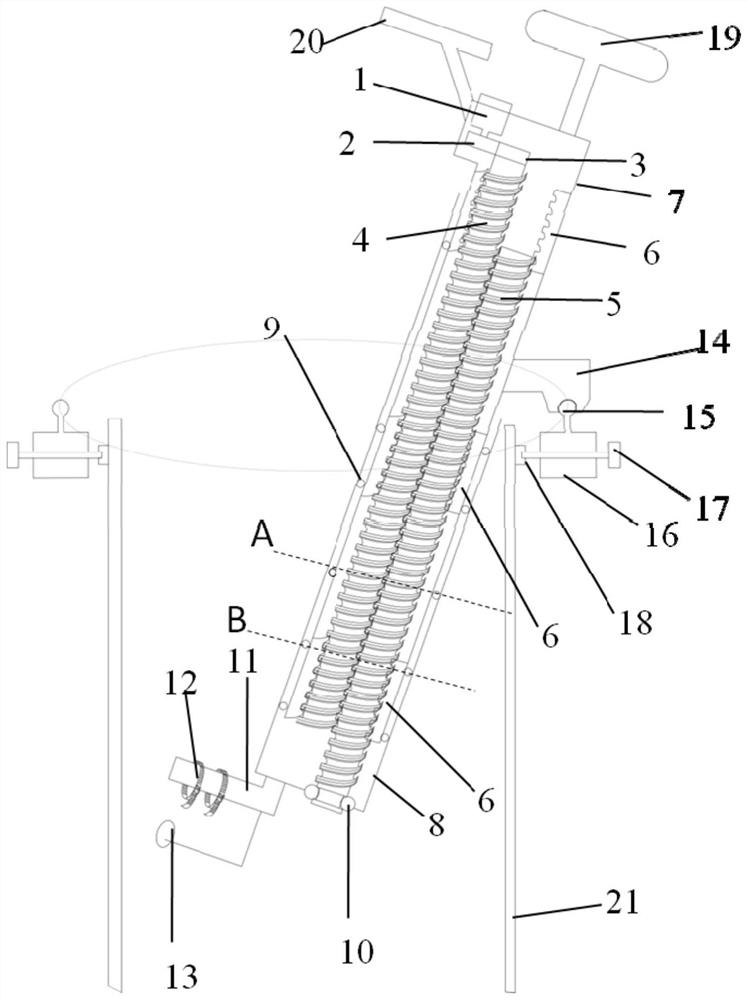

[0029] like Figure 1 to Figure 7 As shown in the figure, the present invention provides an omnidirectional welding device for a small space inside a barrel-shaped workpiece, including an omnidirectional fixing ring and a welding telescopic gun, wherein the welding telescopic gun is installed on the omnidirectional fixing ring, along the circumferential direction of the omnidirectional fixing ring slide.

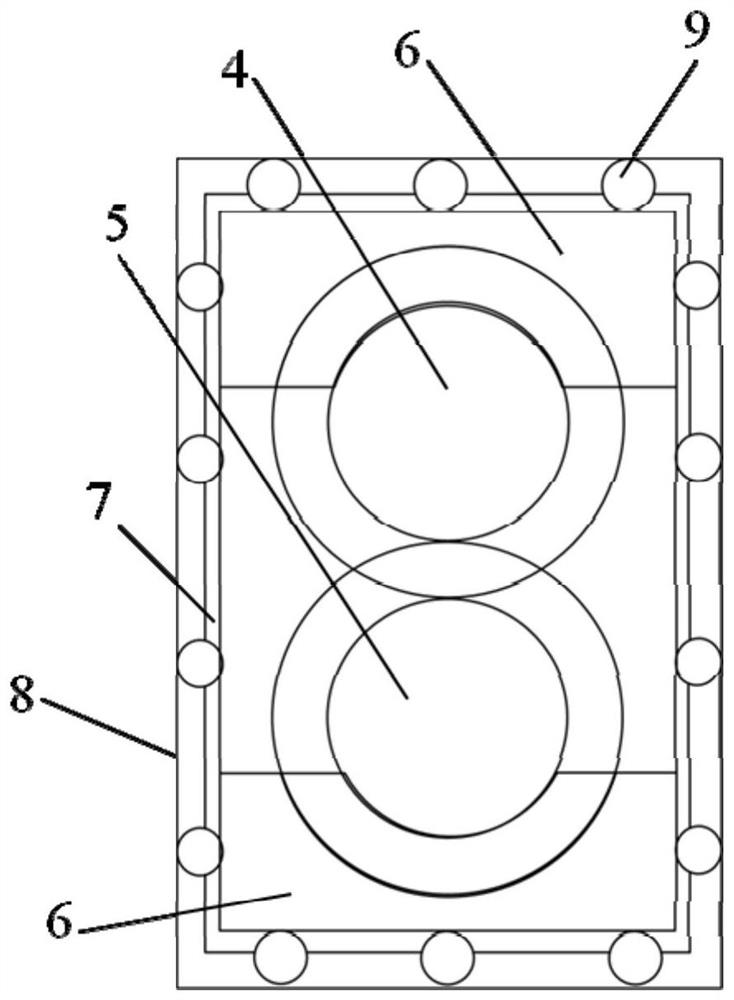

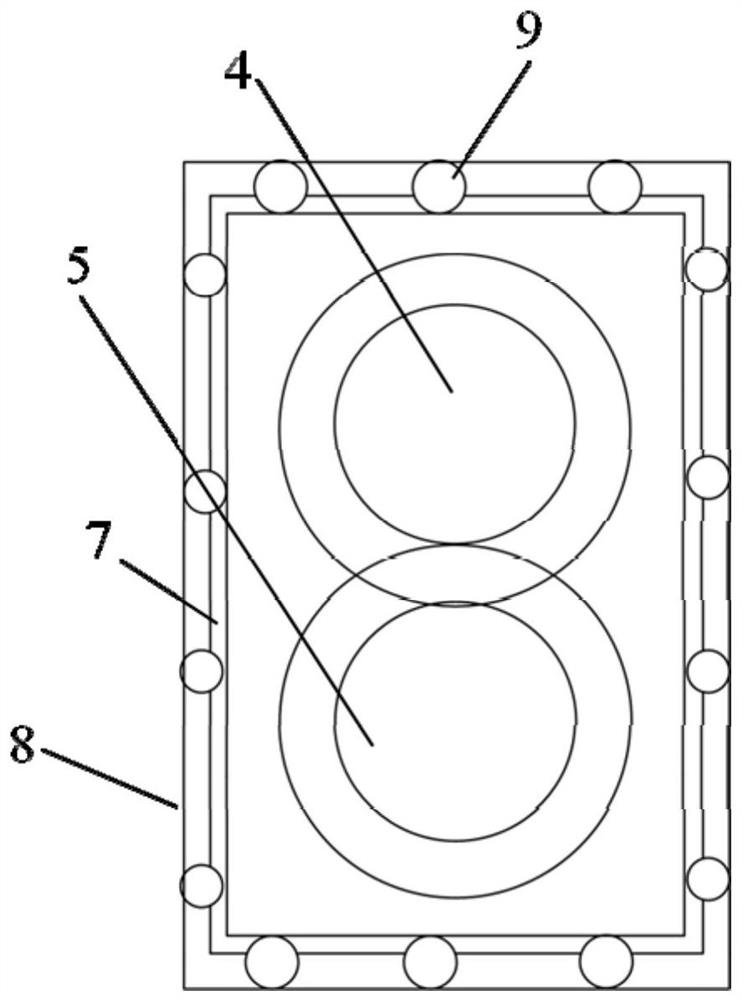

[0030] The welding telescopic gun includes a fixed case 7, the fixed case 7 is a square frame structure, and a driving mechanism is arranged in the inner cavity of the fixed case 7.

[0031] A telescopic case 8 is slidably installed on the outer side of the fixed case 7 , and one end of the telescopic case 8 is drivingly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com