Sealing structure with throttle orifice plate instead of valve

A technology of throttling orifice plate and sealing structure, which is applied to parts of pumping device for elastic fluid, non-variable displacement pump, machine/engine, etc. Adjusting the amount of water is difficult to quantitatively control, increasing the cost of mold opening and material management, etc., to avoid the operation of adjusting the amount of flushing water, facilitate material management, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

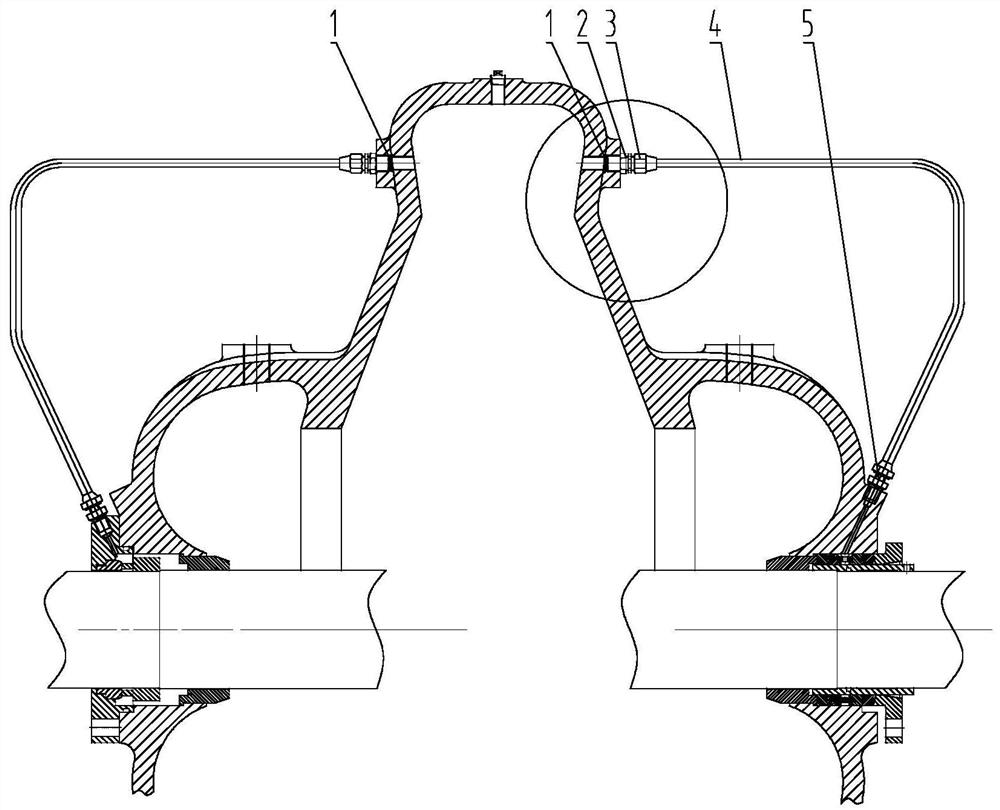

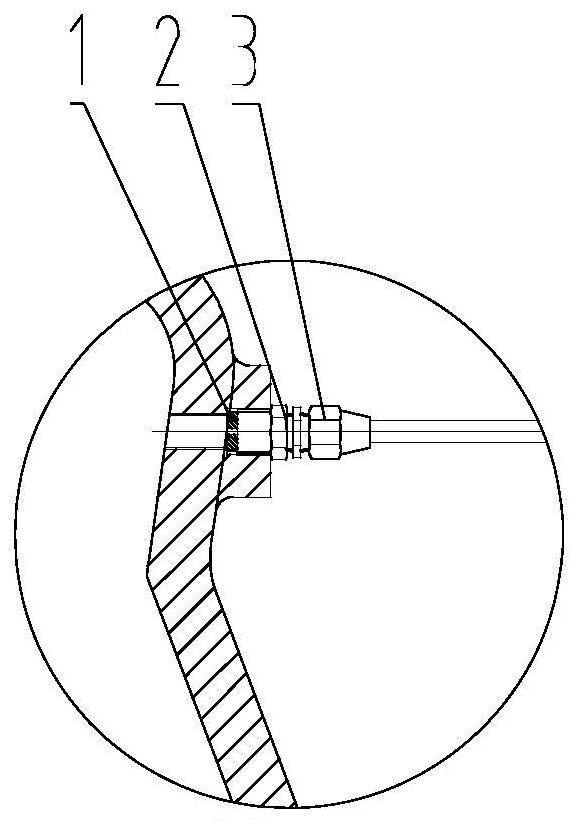

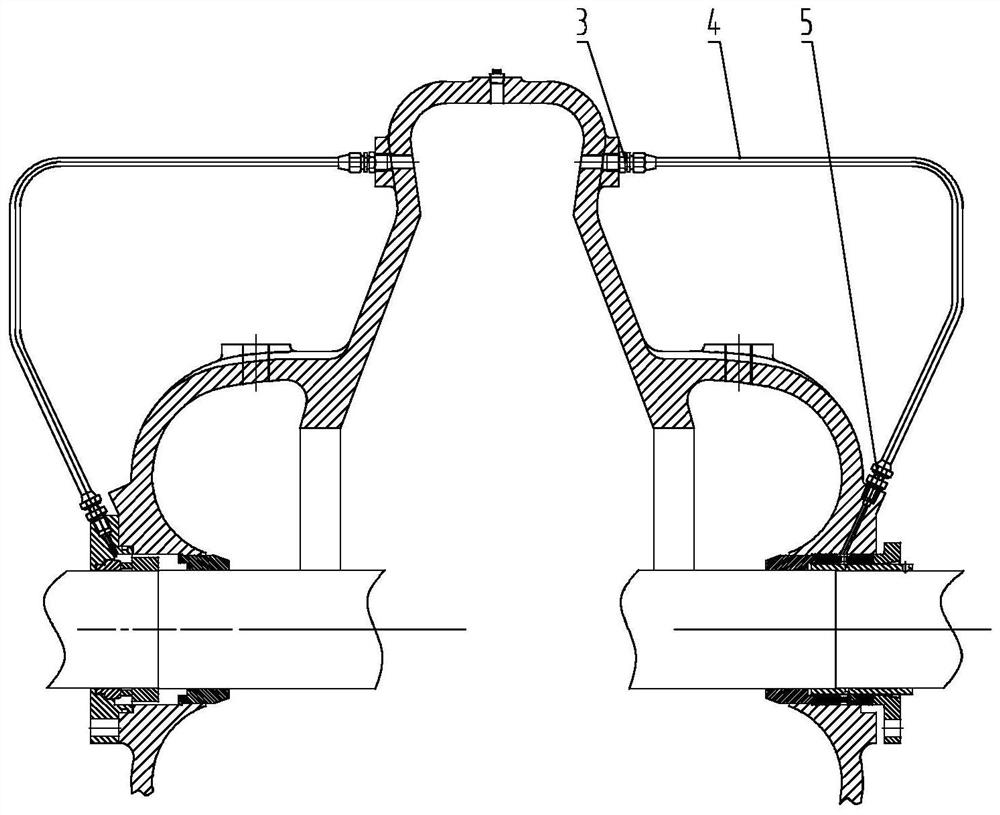

[0020] Picture 1-1 It is a schematic diagram of the sealing and flushing structure of the band throttle orifice of the present invention, Figure 1-2 for Picture 1-1 A partial enlargement of the . figure 2 It is a schematic diagram of the seal flushing structure without a throttle orifice plate of the present invention. As shown in the above figure: the throttling orifice provided by the present invention replaces the sealing structure of the valve, and the throttling orifice replaces the sealing structure of the valve and is installed in the double suction pump. The sealing structure of the throttling orifice replacing the valve includes: The flushing part, the seal flushing part includes the seal flushing pipeline and the seal flushing pipeline accessories matched with the seal flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com