Assembling and welding tool and method for U-shaped rib gasket of steel bridge

A technology for assembling welding tooling and pads, which is applied in the direction of auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of not being able to fit the U-shaped ribs well, difficult on-site operation, complicated manufacturing process, etc., and achieve the top-tightening effect Good, less difficult to operate, less construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

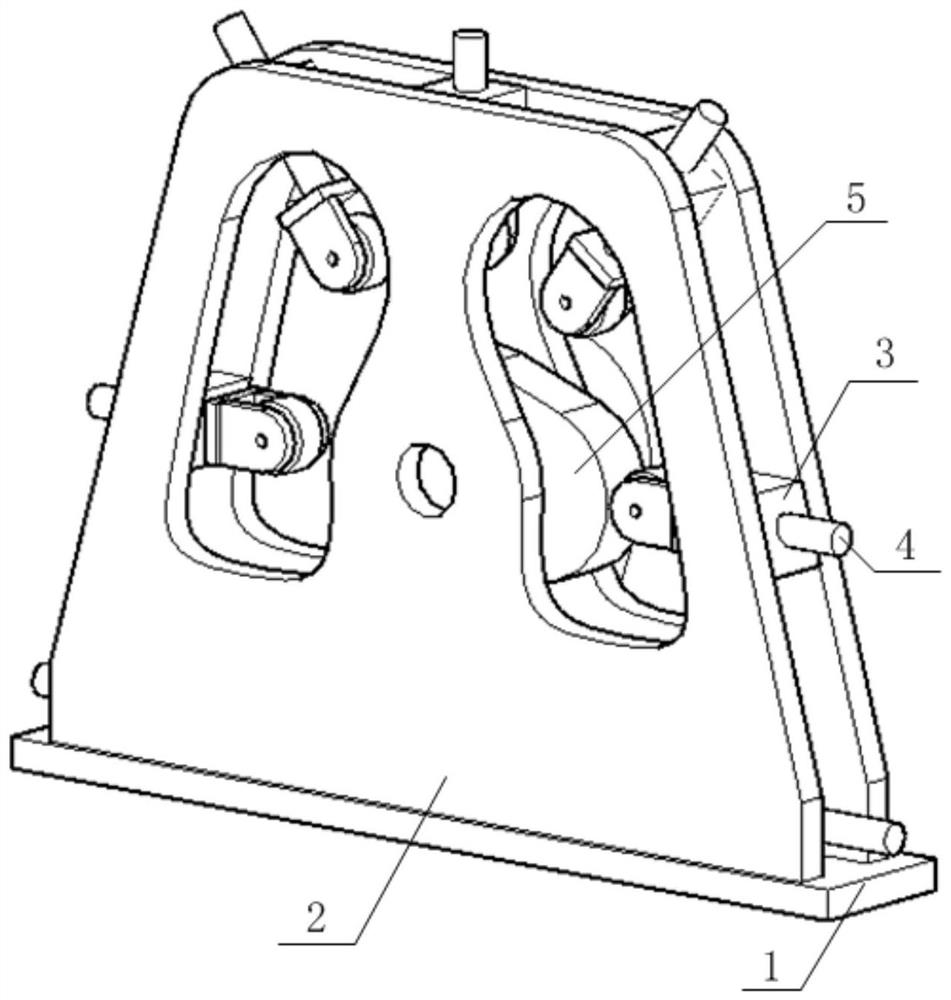

[0030] See also Figure 1 ~ Figure 3 , the embodiment of the present invention provides a steel bridge U-shaped rib liner assembly welding tool, which specifically includes: a bottom plate 1, two support plates 2, a first guide block 3, a first tightening rod 4 and a cam 5; wherein,

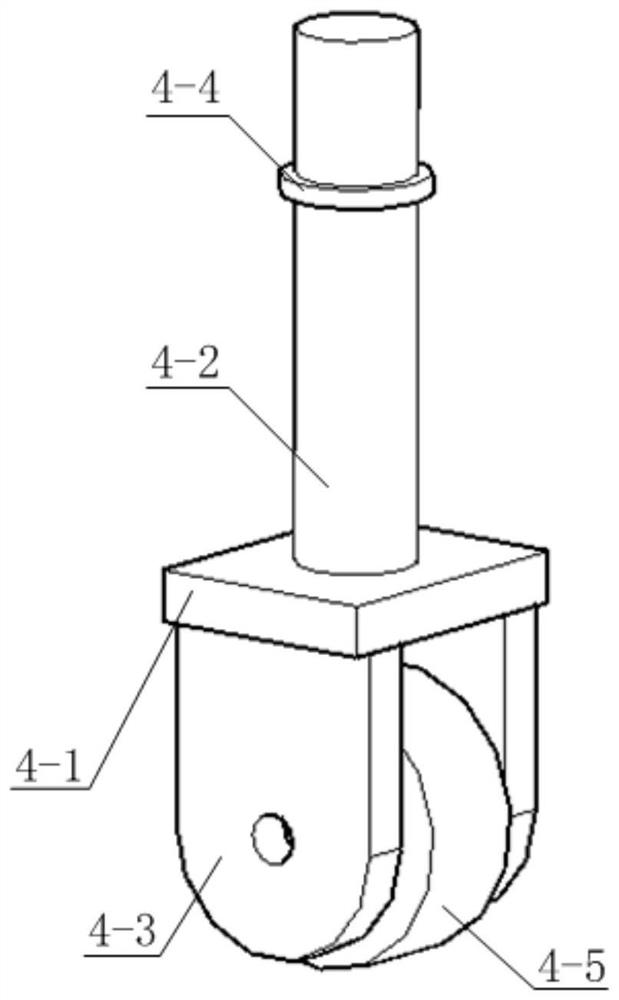

[0031] The two sides of the bottom plate 1 are respectively fixed with the support plates 2, and the first guide blocks 3 are fixed between the support plates 2, and the first tightening rod 4 is inserted into the first guide blocks. 3 and can move along the through hole; the cam 5 is installed between the centers of the support plates 2, and can perform circular motion in the cavity formed between the support plates 2, and When the distal end of the cam 5 rotates to contact with the inner end of the first tightening rod 4, the cam 5 pushes the first tightening rod 4 outward along the through hole on the first guide block 3 Move and tighten the steel liner 6 so that the steel liner 6 is close to...

Embodiment 2

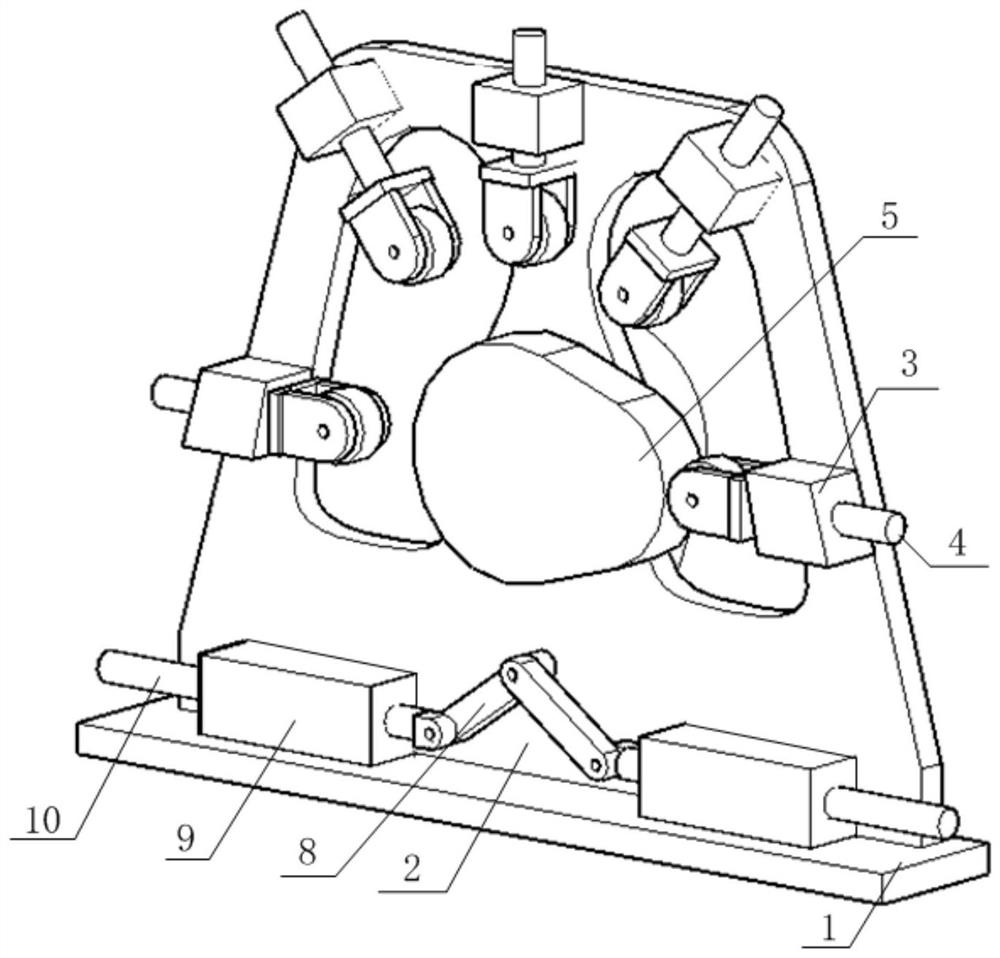

[0038] The embodiment of the present invention provides a method for assembling and welding the U-shaped rib liner of a steel bridge, which is realized by using the welding assembly described in Embodiment 1. Figure 4 ~ Figure 11 , including the following steps:

[0039]Step 1: Bending the steel liner so that its shape fits the shape of the box opening formed by the bridge deck and U-shaped ribs, and placing the bent liner in the box opening, and then the welder Put it into the steel liner formed by pressing and bending, and initially position it in the cavity formed by the bridge deck, and adjust the assembly welding tool to the initial state, such as Figure 4 shown;

[0040] Step 2: Rotate the cam to the vertical downward position, so that the distal end of the cam pushes the top of the double connecting rod to move downward, so that both ends of the double connecting rod move outward, and then push the second clamping rod to move outward to the clamping steel The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com