Assembly method of grate ring of diffuser assembly

An assembly method and diffuser technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of uneven heating of parts, long processing cycle, difficult to ensure the quality of parts and assembly requirements, etc., to avoid blades Extrusion deformation, the effect of ensuring the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

[0026] The method for assembling the grate ring of the diffuser assembly includes the following steps:

[0027] Step 1: Put the parts to be assembled into the heat treatment furnace for overall heating and heat preservation, the heating temperature is 300°C-400°C, the holding time is 1±0.25 hours, and the grate ring is kept at room temperature;

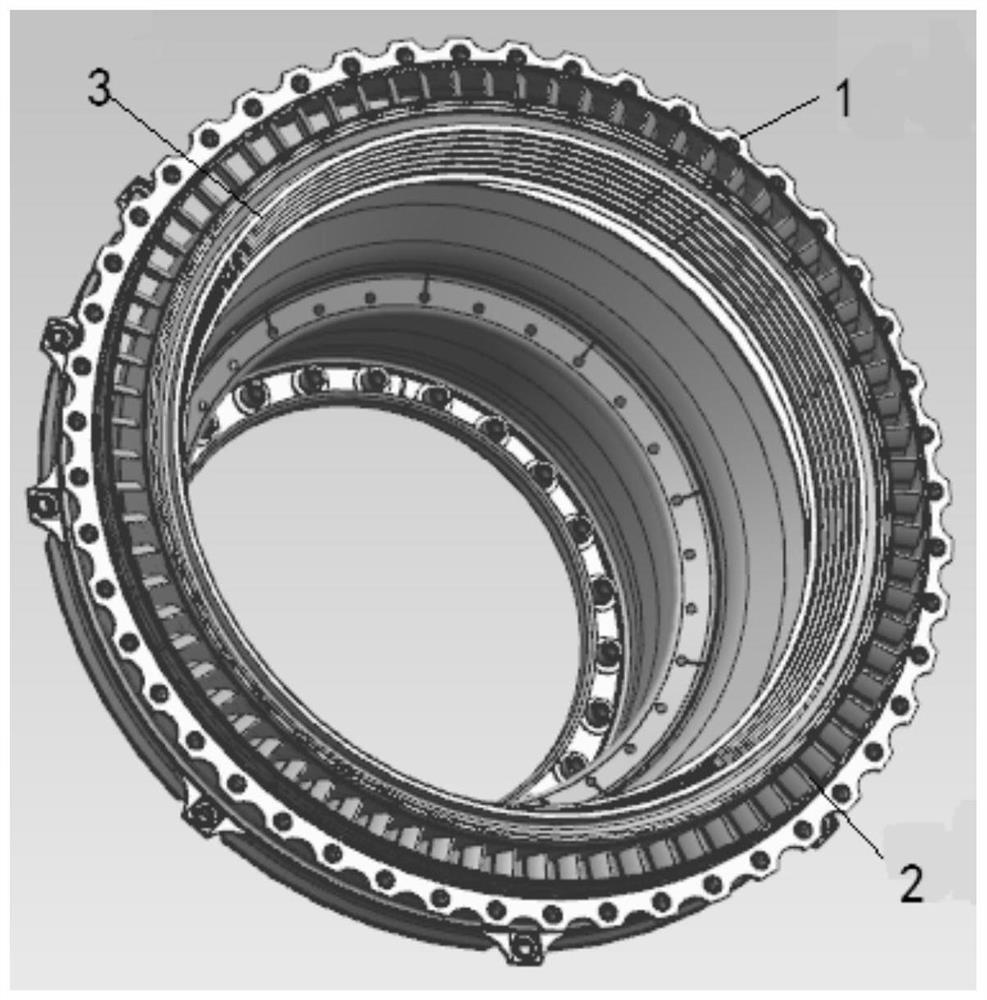

[0028] Step 2: When assembling the grate ring 3, place some gaskets on the bottom of the small end of the part close to the grate ring to be assembled;

[0029] Step 3: Put the grate ring 3 and the gasket under normal temperature into the integrally heated parts; the grate ring 3 is assembled in the installation groove on the inner surface of the inner ring, and the gasket is placed on the inner bottom surface of the installation groove and the grate ring 3 be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com