Gas turbine stationary blade insert installation method and application

An installation method and plug-in technology, which are applied to the installation method and application field of a gas turbine turbulent and stationary blade plug-in, can solve the problems of ineffective cooling, safety accidents, and shortened blade life, and achieve the effect of ensuring the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention is realized through the following technical solutions, a method for installing a gas turbine turbine vane plug-in, specifically comprising steps:

[0033] Calculate the relationship between the plug-in assembly gap and the cooling gas leakage to obtain the plug-in assembly gap; the plug-in assembly gap is 0-1.0mm;

[0034] The relationship between the calculation plug-in assembly clearance and cooling gas leakage; specifically refers to:

[0035] Through three-dimensional CFD calculation, the cold air leakage of the static blades under different installation clearances is obtained, and the corresponding assembly clearance is found according to the requirements of different blades on the cold air leakage;

[0036] Reserve cavity grooves in the inner cavity of the vane;

[0037] Plug-in orthopedics: orthopedize the completed plug-in, and the length of the exposed part of the plug-in is controlled at 3-20mm.

[0038] Orthopedics refers to the use of...

Embodiment 2

[0047] A method for installing a gas turbine turbine stator blade plug-in. The temperature of the first and second-stage stator blades of a gas turbine is very high, requiring efficient internal cooling, and the installation requirements for the plug-in are also relatively high. The specific installation method for the first and second-stage stator blade plug-ins The steps are:

[0048] In the manufacture of hollow stators, a cavity groove is reserved at the bottom of the inner cavity insert to facilitate the assembly of the insert;

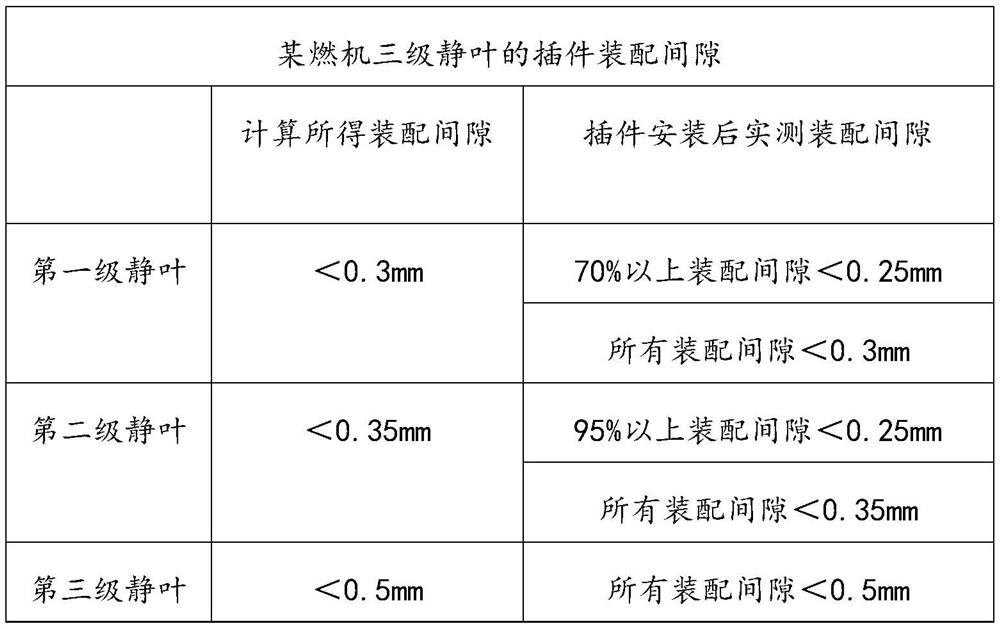

[0049] According to the internal structure of the blade and the cooling airflow conditions, the relationship between the plug-in assembly clearance and the cooling gas leakage is calculated, and a reasonable plug-in assembly clearance requirement is put forward. The theoretical analysis and full three-dimensional CFD calculation and analysis of the first and second stages of a certain gas turbine are carried out to evaluate the plug-in leakage fl...

Embodiment 3

[0054] A method for installing a gas turbine turbine stator blade plug-in. Although the temperature of the third-stage stator blade of a gas turbine is not as high as that of the first and second stages, internal cooling is still required. The specific steps for installing the third-stage stator blade plug-in of a gas turbine are as follows:

[0055] In the manufacture of hollow stators, a cavity groove is reserved at the bottom of the inner cavity insert to facilitate the assembly of the insert;

[0056] According to the internal structure of the blade and the cooling airflow conditions, the theoretical analysis and full three-dimensional CFD calculation and analysis of the third-stage stator blade of a certain gas turbine are carried out to evaluate the plug-in leakage flow, and it is concluded that the assembly clearance of the third-stage stator blade plug-in assembly is required to be 0.5mm.

[0057] Orthopedically improve the finished plug-in, reduce assembly interference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com