A servo motor stator and rotor assembly tooling

A technology for assembling tooling and servo motors, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low assembly efficiency of stators and rotors, and achieve the effect of simple motor assembly process, convenient inspection, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

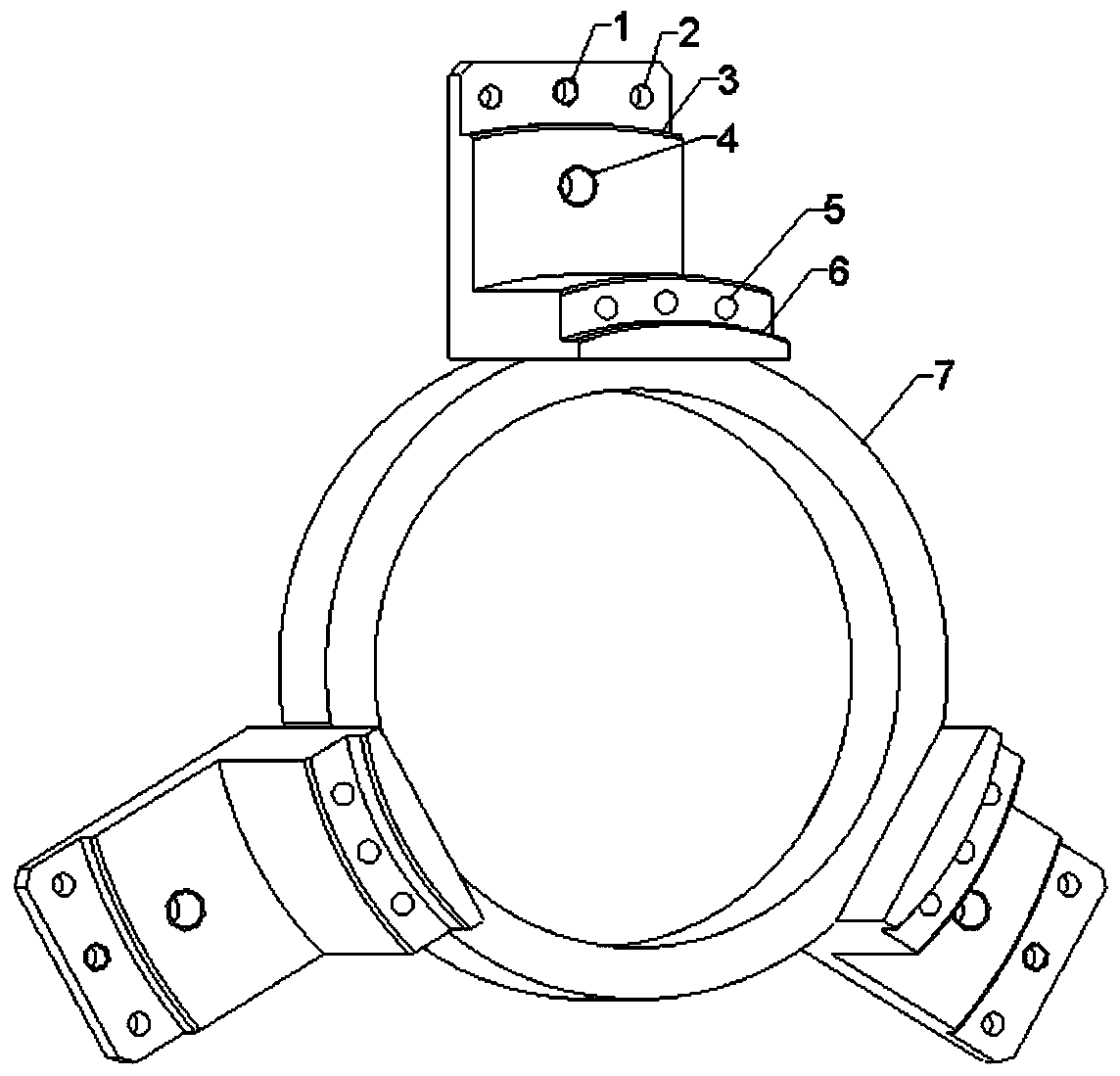

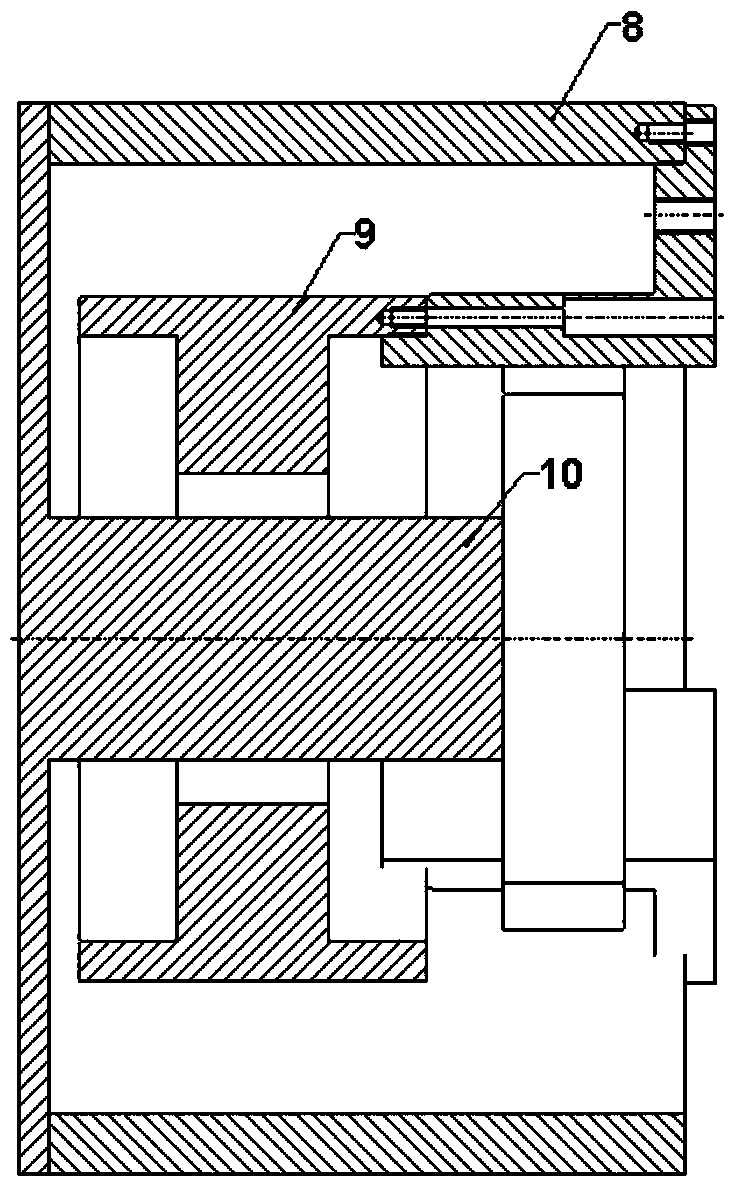

[0014] like Figure 1 ~ Figure 2 As shown, a stator-rotor assembly tooling is composed of an external connection structure, which is a three-block structure in this example, and an internal ring structure. This mechanism includes outer ring stator positioning hole 2, outer ring arc notch groove 3, inner ring fixed rotor positioning hole 5, inner ring arc notch groove 6, retraction threaded hole 1, hoisting hole 4, tooling support ring 7 . Use the positioning hole 2, the circular arc groove 3 of the outer ring to cooperate with the stator 8, the fixed rotor positioning hole 5 of the inner ring and the circular arc groove 6 of the inner ring to cooperate with the rotor 9, and the retreat threaded hole 1 is used when the tooling is disassembled. The hoisting hole 4 is used when lifting the motor or tooling, and the support ring 7 is used when the rotating shaft 10 and the rotor 9 are assembled.

[0015] During the assembly process of the stator and rotor, first use screws to lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com