Bidirectional self-tightening hexagonal sleeve

A hexagonal sleeve and sleeve technology, which is applied in the manufacture of tools, wrenches, screwdrivers, etc., can solve the problems of not being easy to carry and store, occupying a large space, and high cost, so as to achieve easy carrying and storage, convenient adjustment and switching, and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

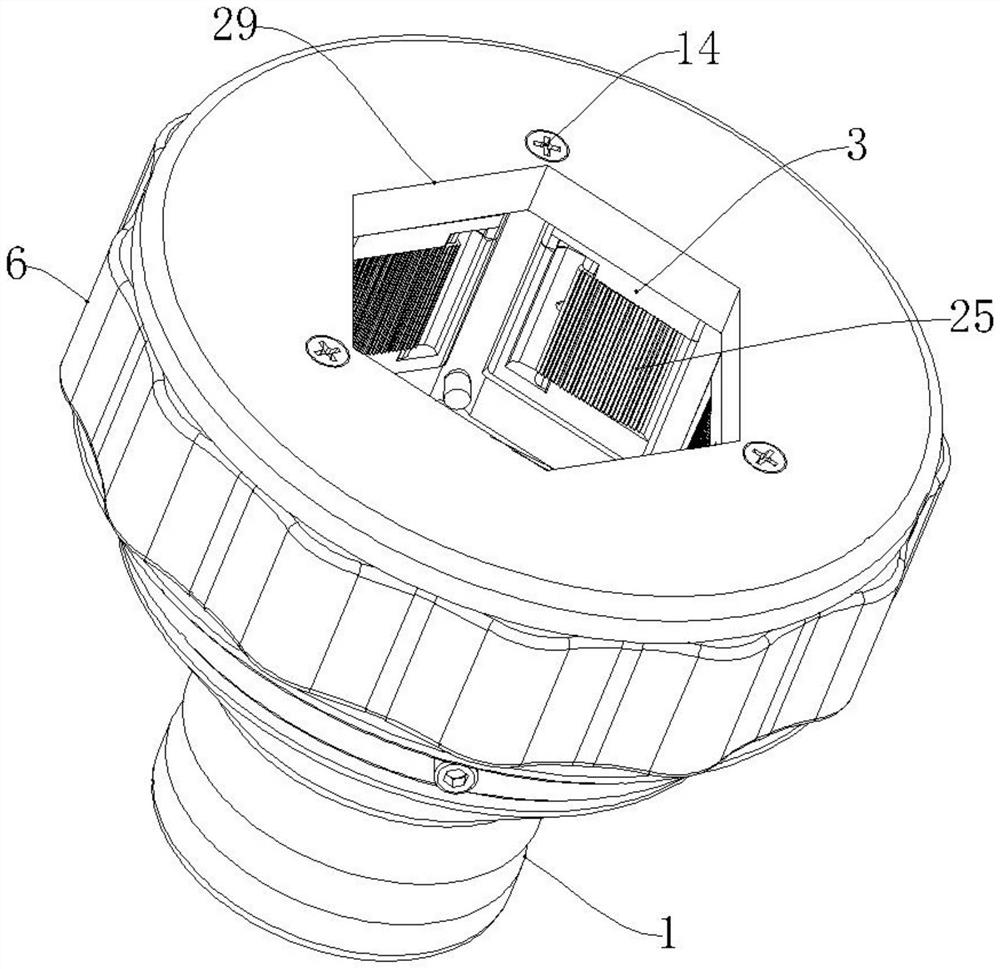

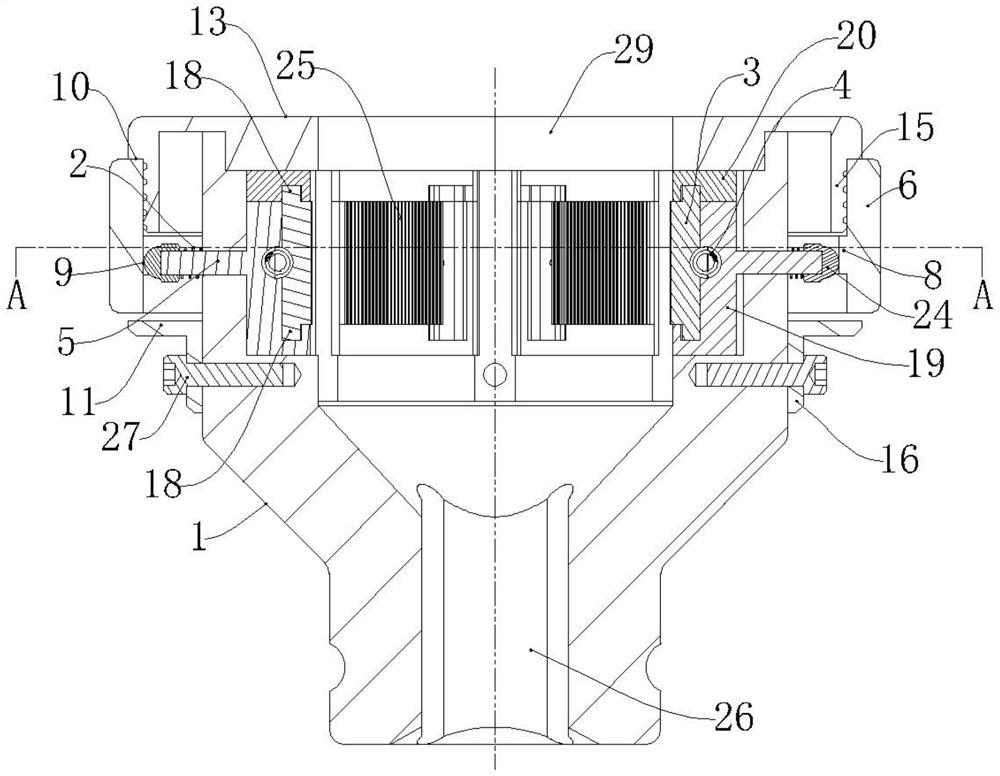

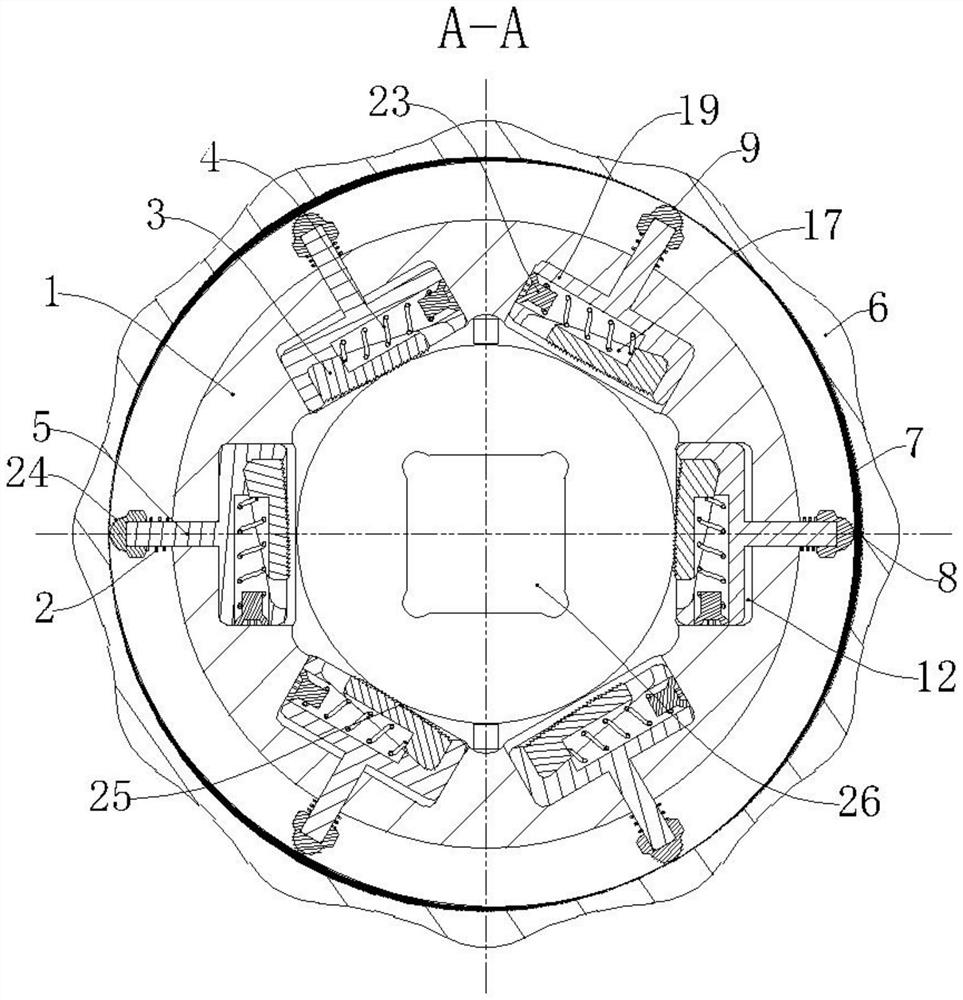

[0028] Figure 1 to Figure 7 Example 1 of the present invention is shown.

[0029] This embodiment provides a bidirectional self-tightening hexagonal sleeve, including a sleeve body 1, a self-tightening unit group and an adjustment mechanism.

[0030] The sleeve body 1 is mirrored with two sets of the self-tightening unit groups, each group of the self-tightening unit groups includes three self-tightening units uniformly distributed along the circumference of the sleeve body 1, and two sets of the self-tightening unit groups. 27 for tightening and loosening of threaded fasteners, respectively.

[0031] The self-tightening unit includes a radial slider, a slider spring 2 , a claw 3 and a claw spring 4 .

[0032] The radial slider is mounted on the sleeve body 1 and can slide along the radial direction of the sleeve body 1. Specifically, the sleeve body 1 is provided with a radial sliding groove 12 inside. The radial slider Sliding fit with the radial chute 12.

[0033] like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com