Energetic material filling device

A filling device and filling technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of charge quality defects, limited equipment adaptability, low filling density, etc., achieve continuous high-efficiency dense filling, and reduce charge quality defects , Improve the effect of packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

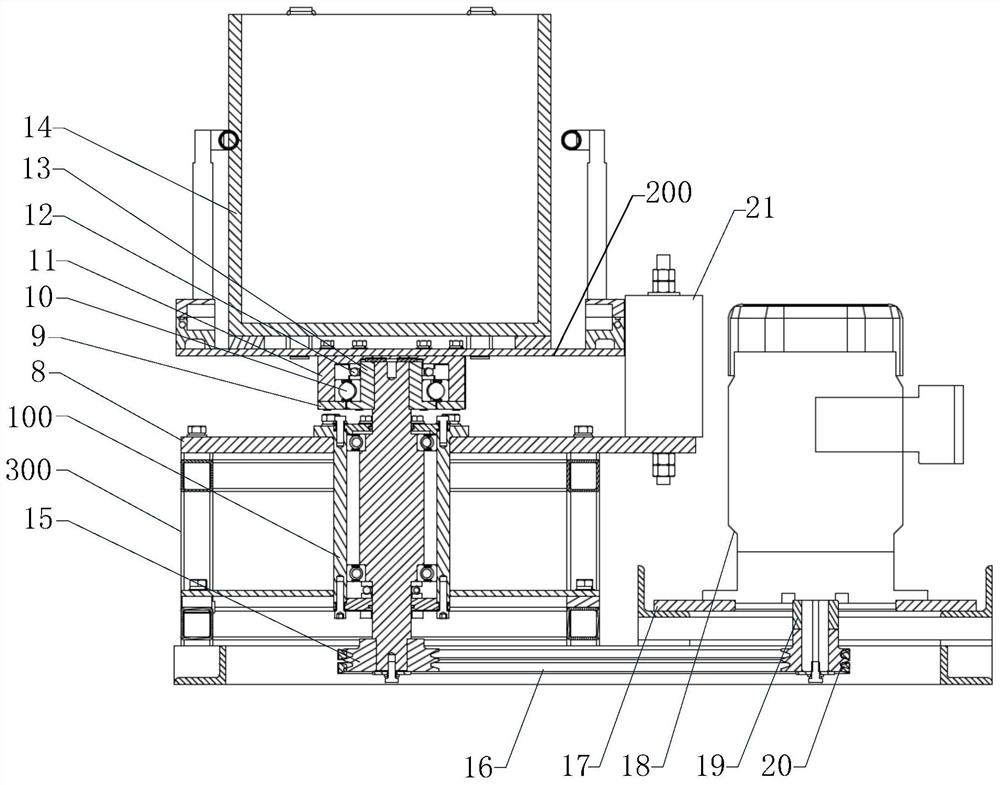

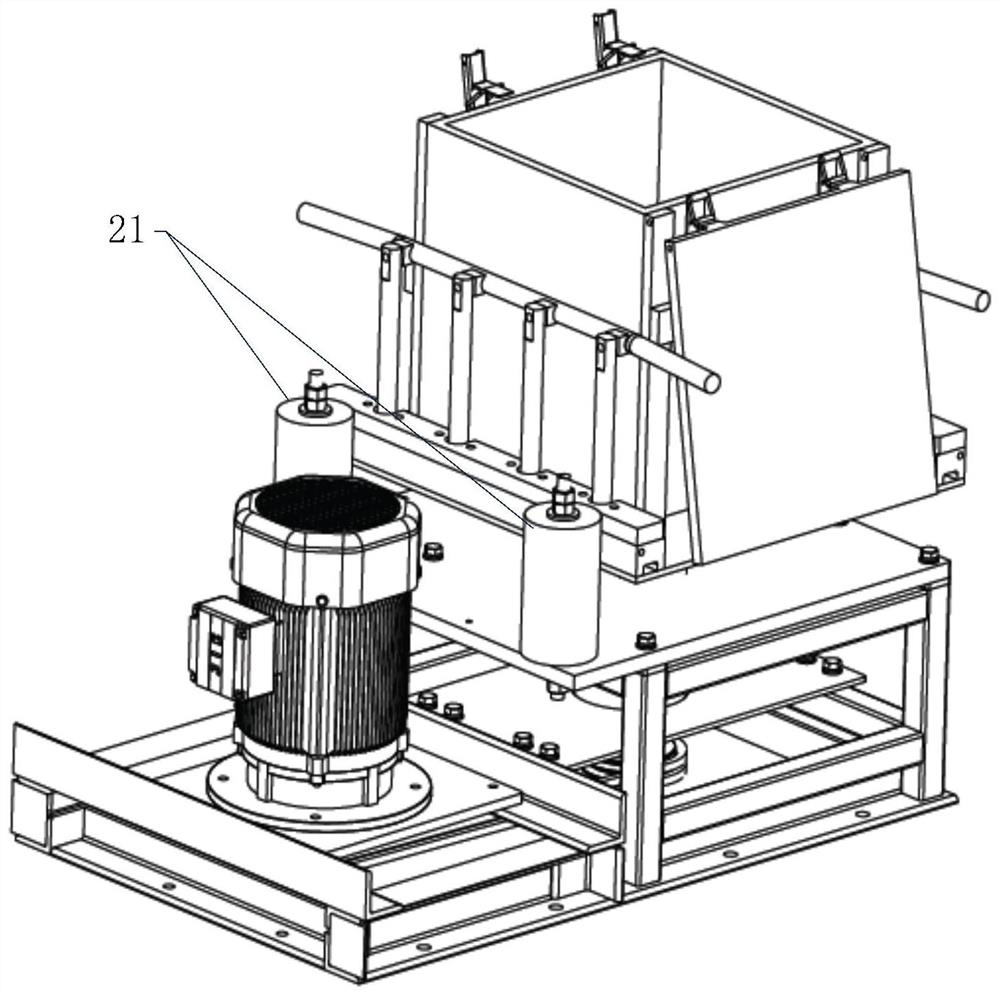

[0048] like Figure 1-Figure 4 As shown, an energetic material filling device includes a driving mechanism, a transmission mechanism 100, an eccentric block 13, a buffer column 21, a filling platform 200 and a frame 300:

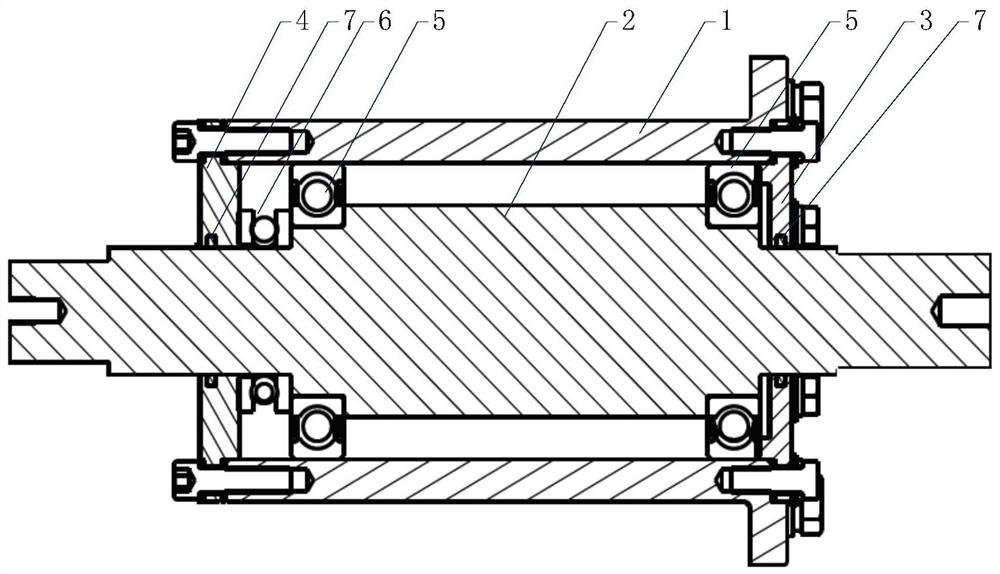

[0049]The transmission mechanism 100 includes a transmission shaft sleeve 1 and a transmission central shaft 2. The transmission shaft sleeve 1 is arranged outside the transmission central shaft 2, and both ends of the transmission central shaft 2 protrude from the transmission shaft sleeve 1. An upper flange cover 3 and a lower flange cover 4 are respectively provided between the transmission shaft sleeve 1 and the transmission center shaft 2 at both ends. The transmission shaft sleeve 1 and the frame 300 are detachably connected. Preferably, the transmission shaft The outer wall of the upper end of the sleeve 1 extends radially outward to form an annular convex edge, and the annular convex edge is connected with the transmission mechanism mounting plate 8 ...

Embodiment 2

[0061] This embodiment is based on Embodiment 1, and the difference from Embodiment 1 is:

[0062] The explosion-proof motor is replaced by an air motor, and the rotation speed of the air motor is controlled by an explosion-proof proportional pressure reducing valve, which is suitable for dense filling of energetic materials with high danger level and strong destructiveness.

Embodiment 3

[0064] This embodiment is based on Embodiment 1, and the inner side walls of the upper flange cover 3 and the lower flange cover 4 are both provided with a rotary sealing ring 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com