Coil stock carrying vehicle

A technology for transporting vehicles and roll materials, applied in the direction of lifting devices, etc., can solve the problems of inconvenient paper roll handling, paper roll slipping, paper roll pressure loss, etc., to improve convenience and stability, and avoid excessive clamping force of roll materials big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

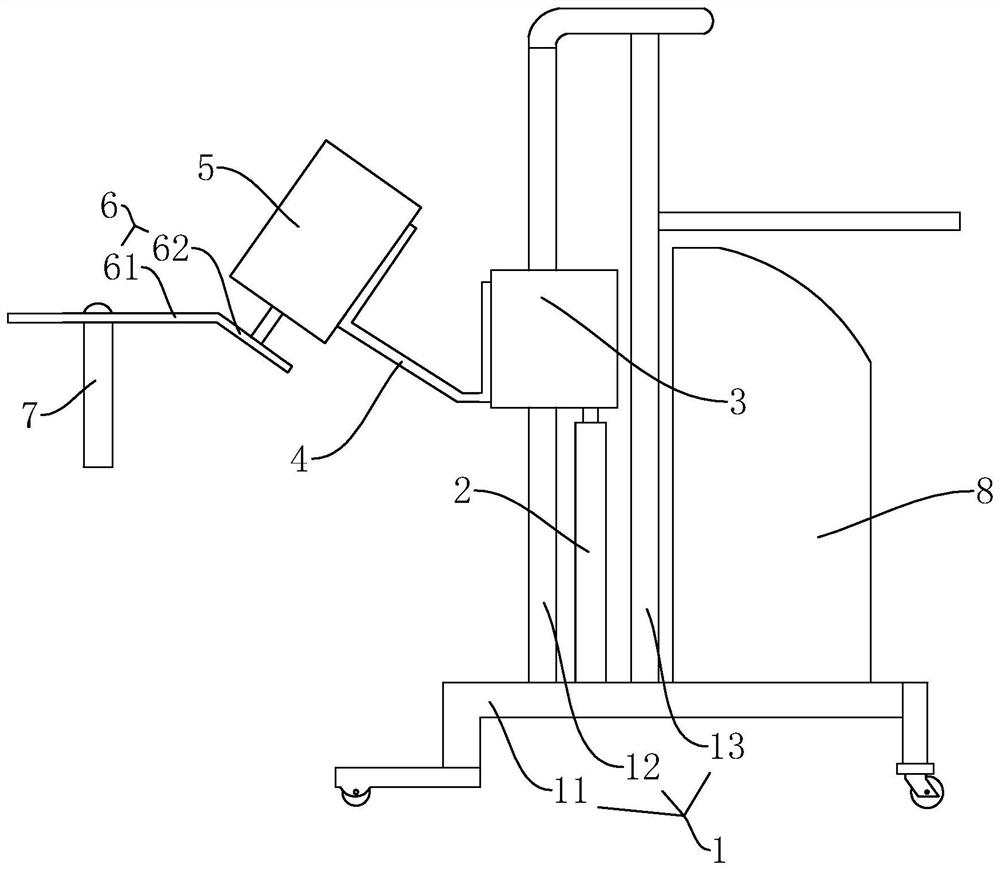

[0017] combine figure 1 The coil material handling vehicle of the present invention will be further described.

[0018] A coil material handling vehicle is characterized in that it includes a vehicle frame 1 , a lifting plate 3 , a turning part 5 and an expansion shaft 7 . The frame 1 has a base frame 11 with pulleys, an armrest frame 13 fixed on the base frame 11 and a control box 8 . The lift plate 3 is movably fitted on the vehicle frame 1, and is connected with a driving component 2 that drives the lift plate 3 to move up and down on the vehicle frame 1; On the lifting plate 3, a support plate 6 is connected to the output shaft of the turning part 5 to drive the support plate 6 to rotate, and the support plate 6 has a transport position and an upper and lower material position when rotating; the expansion shaft 7 is installed on the support plate 6. When the support plate 6 is in the upper and lower material positions, the expansion shaft 7 is located below the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com