Detection device for detecting durability of vehicle shock absorber sleeve assembly

A detection device and shock absorber technology, which is applied in vehicle testing, vehicle suspension/shock absorbing mechanism testing, measuring devices, etc., can solve the problems of delayed vehicle and shock absorber design and development progress, long test time, etc., to achieve Easy to build and maintain, simple and easy to use device, saving experimental time and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

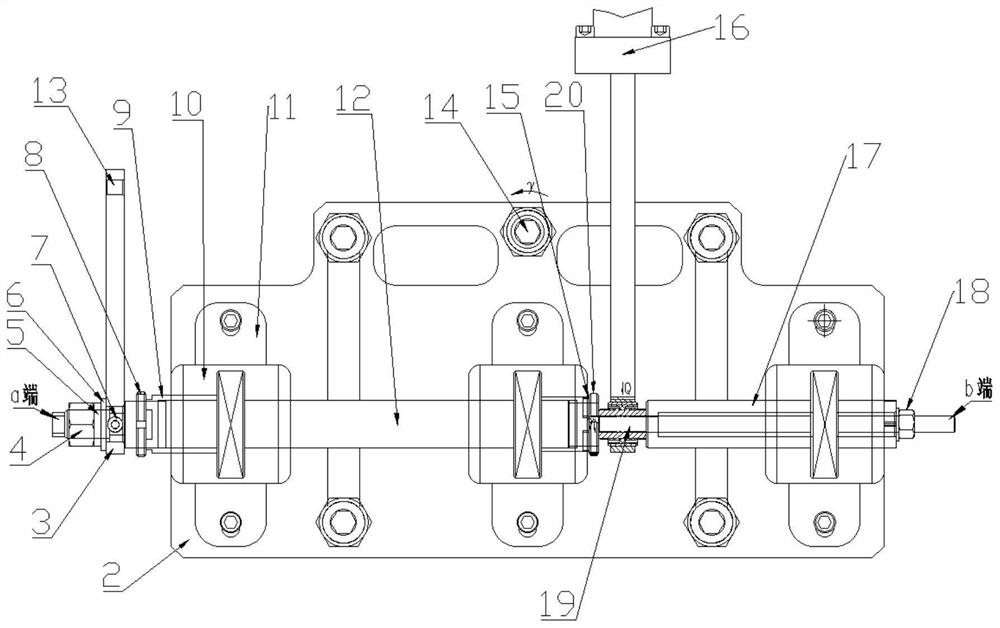

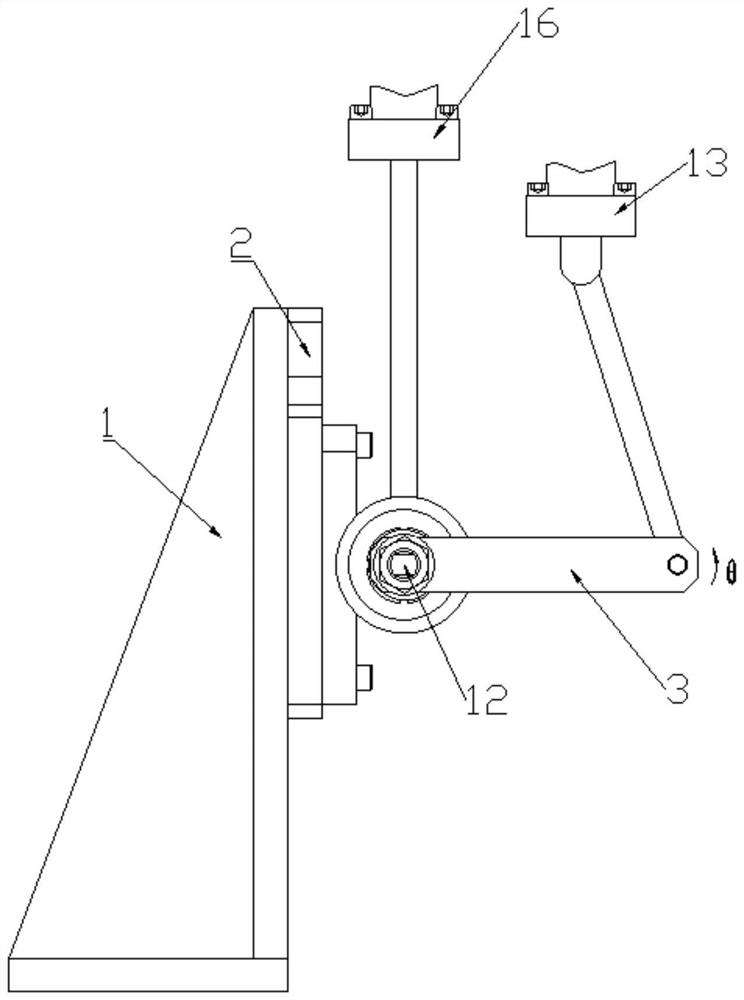

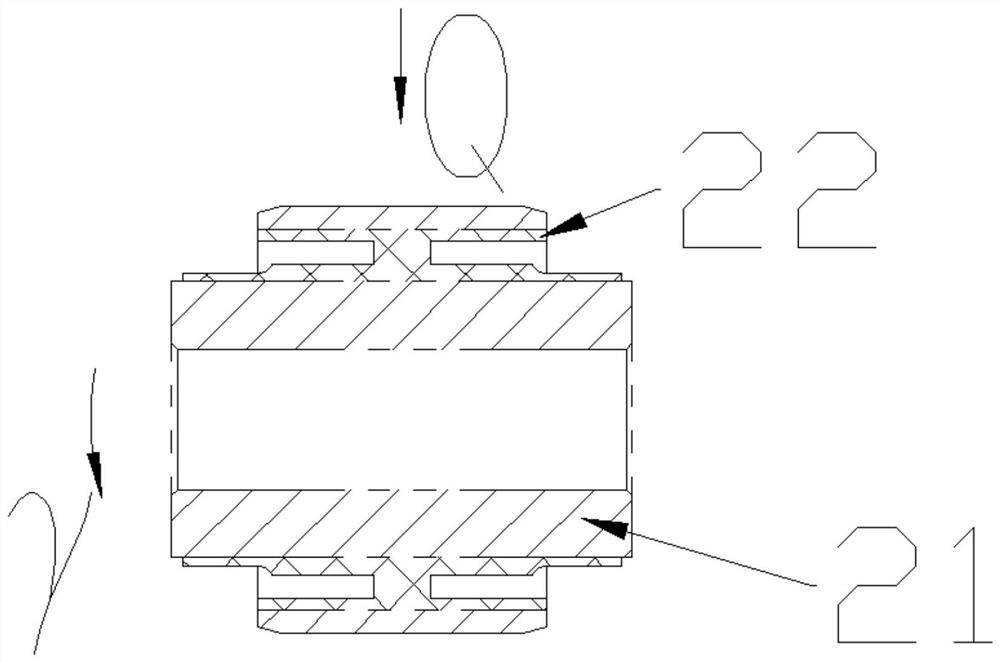

[0027] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a detection device for detecting the durability of a shock absorber bushing assembly of a vehicle, comprising: a bracket 1, a mounting plate 2, a first actuator 16, a second actuator 13, a first The bearing 10 , the second bearing, the third bearing and the torsion bar 12 , the mounting plate 2 is connected with the bracket 1 , and the contact surface of the bracket 1 and the mounting plate 2 is arranged vertically. The first bearing 10, the second bearing and the third bearing are all connected with bearing seats 11, the three bearing seats 11 are all connected with the mounting plate 2, the second bearing is located between the first bearing 10 and the third bearing, the torsion bar 12 Passing through the first bearing 10 , the second bearing and the third bearing, the end of the first bearing 10 away from the second bearing is mounted with the first bushing 9 , and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com