Precision testing device for current-carrying friction pair of conductive slip ring of satellite

A technology of conductive slip ring and current-carrying friction, which is applied in the direction of measuring devices, testing wear resistance, and testing material strength by applying repetitive force/pulsation force, etc. problems, to facilitate measurement and characterization, ensure positioning accuracy, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

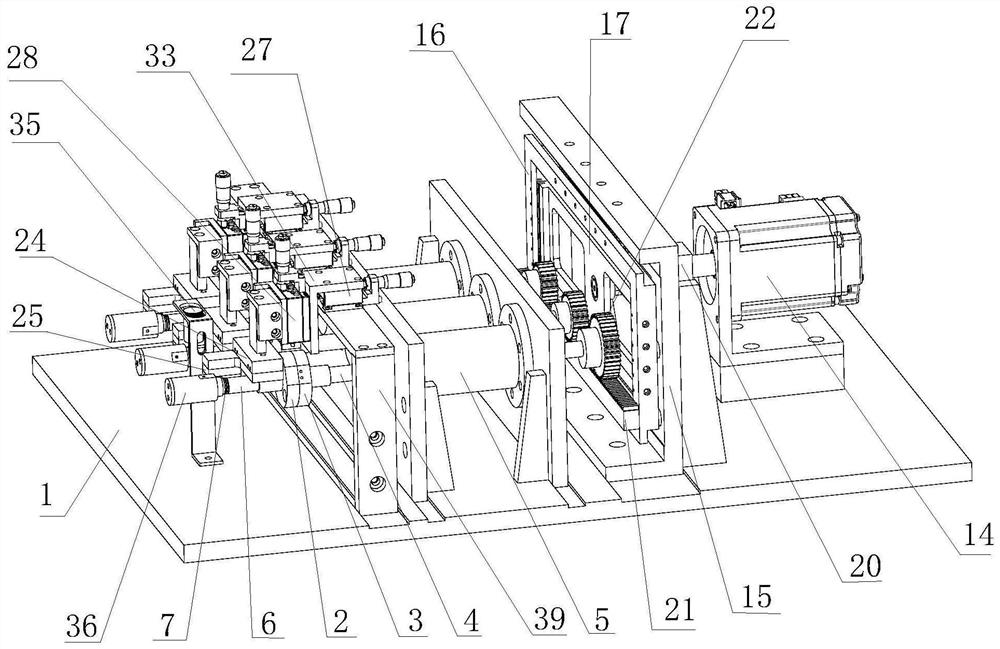

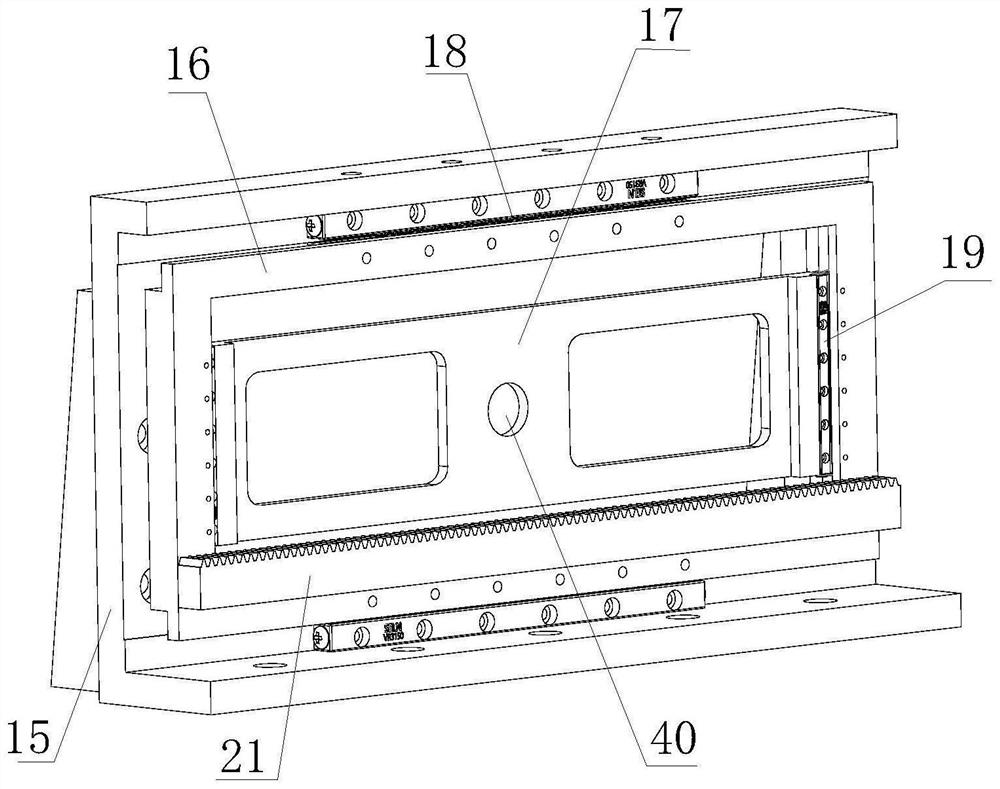

[0037] see Figure 1 to Figure 8 , this embodiment discloses a precision test device for satellite conductive slip ring current-carrying friction pairs, including a base 1, at least one set of test components is arranged on the base 1, three sets of test components are used in this embodiment, three sets of test components The components are arranged sequentially in the front-to-back direction. Each set of test components includes an upper sample loading and measuring mechanism, a lower sample detachable positioning mechanism, a temperature measurement module, and a water cooling module.

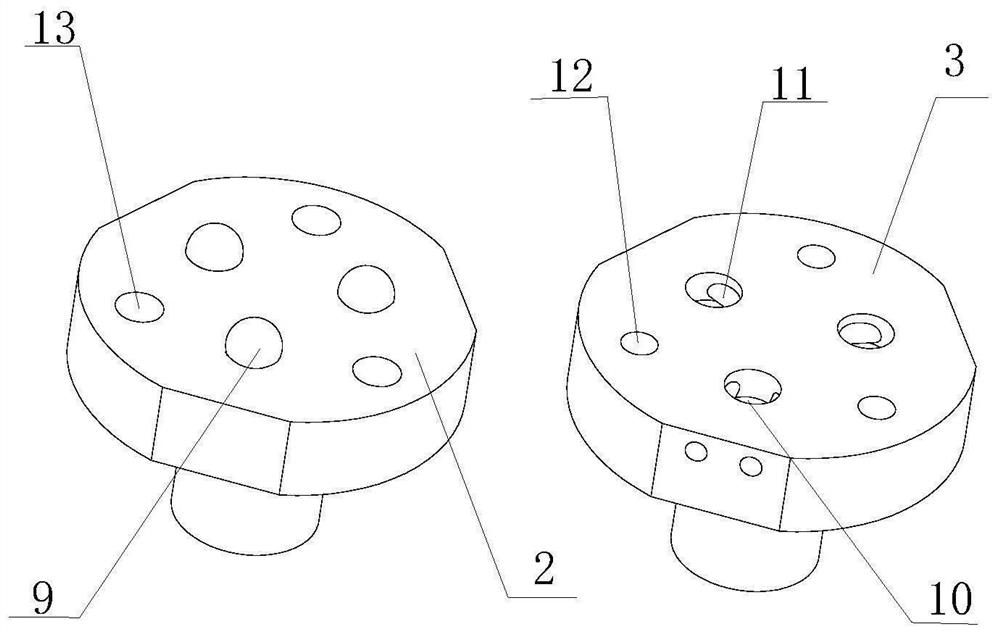

[0038] The detachable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com